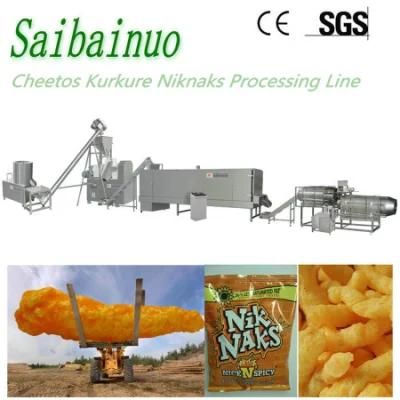

Jinan Saibainuo Single Screw Cheetos Kurkure Making Machine

Yuyao Mingbang Spray Packing Co., Ltd. / 2022-07-05

- Certification:CE, ISO9001

- Power Source:Electric

- Process:Thermal Processing

- Automatic Grade:Automatic

- Application:Chips, Cheetos; Kurkure; Niknaks

- Customized:Customized

=== Base Info ===

- Model NO.:DLG

- Product Name:Cheetos Kurkure Machine

- Capacity:100kg,H, 200kg,H, Higher

- Motor:ABB,Siemens

- Inverter:ABB, Delta

- Guarantee:1 Year

- Machine Materials:Stainless Steel

- Raw Materials:Corn Grits

- Transport Package:Wooden Box

- Specification:Stainless Steel Food Grade Materials

- Trademark:Saibainuo

- Origin:China

- HS Code:84388000

- Production Capacity:50 Sets,Month

=== Description ===

Basic Info.

Model NO. DLG Product Name Cheetos Kurkure Machine Capacity 100kg/H, 200kg/H, Higher Motor ABB/Siemens Inverter ABB/ Delta Guarantee 1 Year Machine Materials Stainless Steel Raw Materials Corn Grits Transport Package Wooden Box Specification Stainless Steel Food Grade Materials Trademark Saibainuo Origin China HS Code 84388000 Production Capacity 50 Sets/MonthProduct Description

Jinan Saibainuo Single Screw Cheetos Kurkure Making MachineryThe Cheetos Kurkure Making Machine is divided into fried and dried. The latest squeezing technology makes the product crispy and delicious.

Introduction for Cheetos Kurkure Making Machine :

Cheese Corn curls Kurkure is a kind of extruded snacks, very crunchy and great in taste. cheese curls Kkurkure is made by extrusion process. The corn grits are moisturized in a vertical mixer with water, oil then feed to the Rotary Head Extruder. In the extruder, due to excess heat and pressure from the screws the meal gets heated and the moisture content gets reduced. The meal passes through the die and gets cut by the cutting knifes into required lengths. The nik naks kurkure is fried in cooking oil and then cooled before flavoring. Seasonings are sprayed on the nik naks to improve their taste.

Cheetos Rotary Head Extruder has the following Features:

1,The Cheetos Nik Naks Making Machine is divided into fried and dried.

2,The latest squeezing technology makes the product crisp and delicious.

3,Design an exquisite and precise control system.

4,the key components of brass casting, with good abrasion resistance.

5,Vibrating feeding makes the feeding evenly and adjustable.

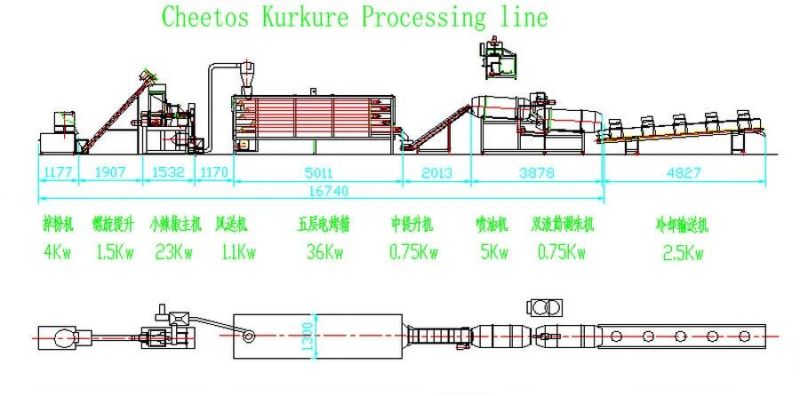

Production Flow for Cheetos Kurkure Nik Naks Making Machine :

Baked cheetos kurkure processing line

Flour Mixer → Cheetos Extruder → Conveyor → Rotary Sifter → Elevator → Oven → Oil Spray Flavoring Line

Fried cheetos kurkure processing line

Flour Mixer → Cheetos Extruder → Conveyor → Rotary Sifter → Elevator →Fryer → Flavoring Line → Packing

Flow chart for Cheetos Kurkure Nik Naks Making Machine:

We can design the cheetos kurkure curls making machine layout according to the dimension of customers' factory.

Final product photos of cheetos kurkure snacks:

Technical parameters for Kurkure Nik Naks Cheetos Production Line:

| Model Parameter | Installed Power | Power Consumption | Output | Size |

| DLG 76x1 | 120kw | 84kw | 120-150kg/h | 18x2x4m |

| DLG76x2 | 150kw | 105kw | 240-300kg/h | 22x2x4m |

| DLG 76x3 | 190kw | 133kw | 400-450kg/h | 26x2x4m |

Kurkure Cheetos Production Machine Line in Factory

Welcome come to visit us, our company is in Jinan City,Shandong Province,China.

If any need or any questions for our machines, please send inquiry to us.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23