Holographic Thermal Transfer Laser Glitter Film Embossing Machine Sg1200

Longgang Xinxin Printing Machinery Co., Ltd. / 2022-06-27

- After-sales Service:Factory Service

- Warranty:1 Year Warranty

- Type:BOPP Pet Embossing

- Driven Type:Electric

- Color & Page:Single Color

- Usage:Card Printer, Paper Printer, Hologram Laser Embossing

=== Base Info ===

- Model NO.:SG1200

- Computerized:Computerized

- Automatic Grade:Automatic

- Application:Artificial Leather, Paper, Aluminum, Fabric, BOPP Pet

- Transport Package:Plastic Around Woodens Pallet

- Specification:3800x2200x3000mm

- Trademark:ret

- Origin:China

- HS Code:8420100090

- Production Capacity:2 Set,Month

=== Description ===

Basic Info.

Model NO. SG1200 Computerized Computerized Automatic Grade Automatic Application Artificial Leather, Paper, Aluminum, Fabric, BOPP Pet Transport Package Plastic Around Woodens Pallet Specification 3800x2200x3000mm Trademark ret Origin China HS Code 8420100090 Production Capacity 2 Set/MonthProduct Description

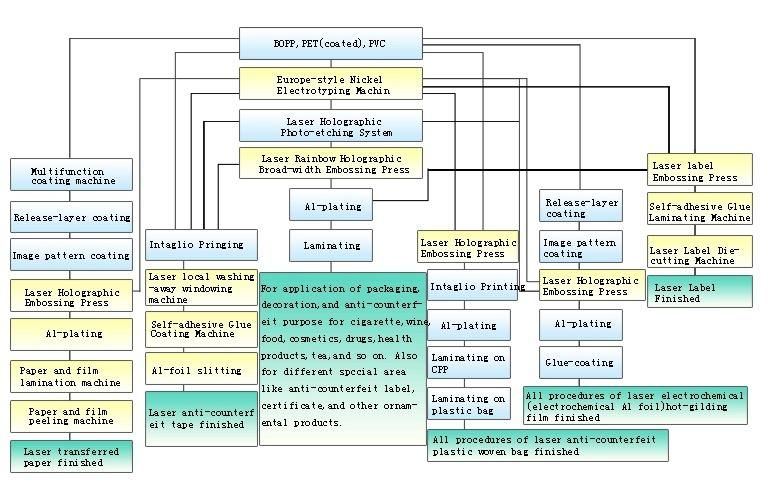

Bopp Pet Seamless Hologram Laser Embossing Machine

1. Description:

This machine is designed by introducing advanced technology of membrane press from abroad and combining with years of experience in membrane press production. This machine is suitable for holographic laser holographic laser high quality PET rainbow pigment mask, light column membrane, hot stamping film and transfer film. Glitter silky film,Lenticular film,Glitter pp film,Glitter brush film. The molding thickness is 12-200um. The working principle is to heat and transfer the holographic laser image and text copied on the nickel plate to the film material.

The machine can effectively solve the common black spot defect of plate stitching on the film surface, greatly improve the utilization rate of materials and reduce the production cost, and the continuous film pressure is stable and the laser vision effect is clearer.

1. Mitsubishi tension controller and Mitsubishi A700 series frequency converter are used to implement vector closed-loop control, and optical fiber sensor PID control is used to implement no plate gap control.

2. Adopt Panasonic PLC and vinylon HMI automatic control, convenient and practical operation.

3. The heating system is equipped with a set of wjd-36 external circulation heater. The machine is heated by oil temperature, and the conduction oil is closed for circulation.

4. Equipped with high-temperature heat conduction system, the temperature can be adjusted from 30-200 ºC (Fuji can only adjust the temperature), and the heating speed is fast (generally, it takes 20 minutes from 30-200 ºC).

5. Equipped with automatic oiling and oil blowing system to make the change roller simple and fast, save the time of change roller (generally 20 minutes) and improve the production efficiency.

6. Adopt roller type pulse counting touch screen, with high-speed and accurate electronic display.

2. Main Technician Specification:

| Model | JGLS-1200 |

| Speed | 65m/min Max.(40-60m/min for PET,BOPP coating film) |

| Raw Embossing Width | 1100mm |

| Raw Material Diameter | 1200mm |

| Thickness | 12-200um(BOPP,Laminating Film,Transfer Film) |

| Roller Diameter | 600mm(pattern plate 1500mm length,width according material) |

| Core Diameter | 76mm in,rewinding 0-50mm |

| Rewinding Diameter | 600mm |

| Power | 60kw(start & heating power ~35kw,working power ~25kw) |

| Pressure | Oil system Pressure adjust:7Mpa |

| Voltage | 380v 50hz |

| Cooling sytem | 7.5kw water cooling 5P |

| Heating system | ~200ºC Adjustable electric heating (90L heating oil input) |

| Overall Dimension | 3800x2200x3000mm |

| Electric Box Dimension | 1050x750x1920mm |

| Heating Box Dimension | 1550x850x1900mm |

| Cooling Diamension | 1200x560x1320mm |

| Weight | 6800kg |

- Embossing machine(two parts)

- Electric box

- Heating box

- Cooling box

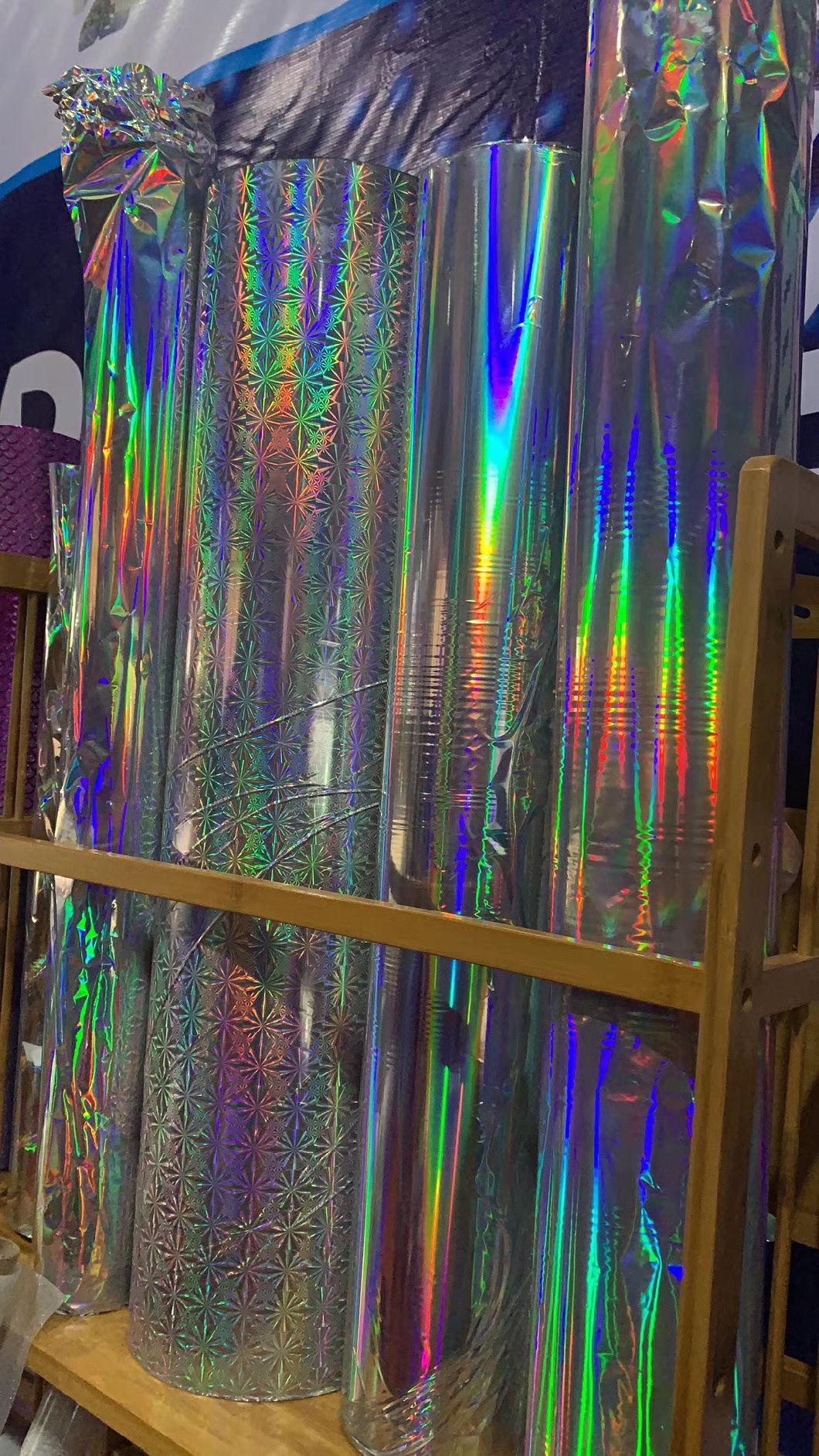

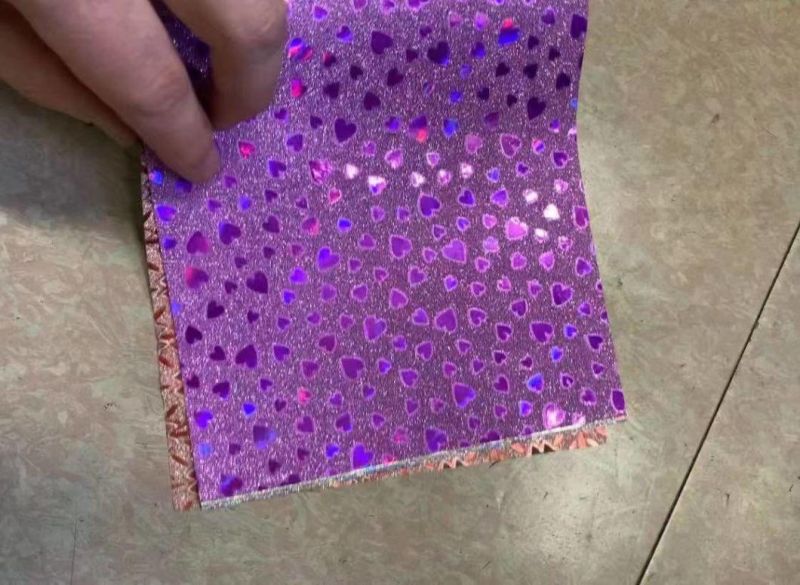

Sample photos:

Machine photos:

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23