Diamond Sapphire Crystal Magnetic Artificial Gemstone Multi Wire Sawing Cutting Machine

Guangzhou Yongjia Iron-Printing and Tin-Making Co., Ltd. / 2022-06-27

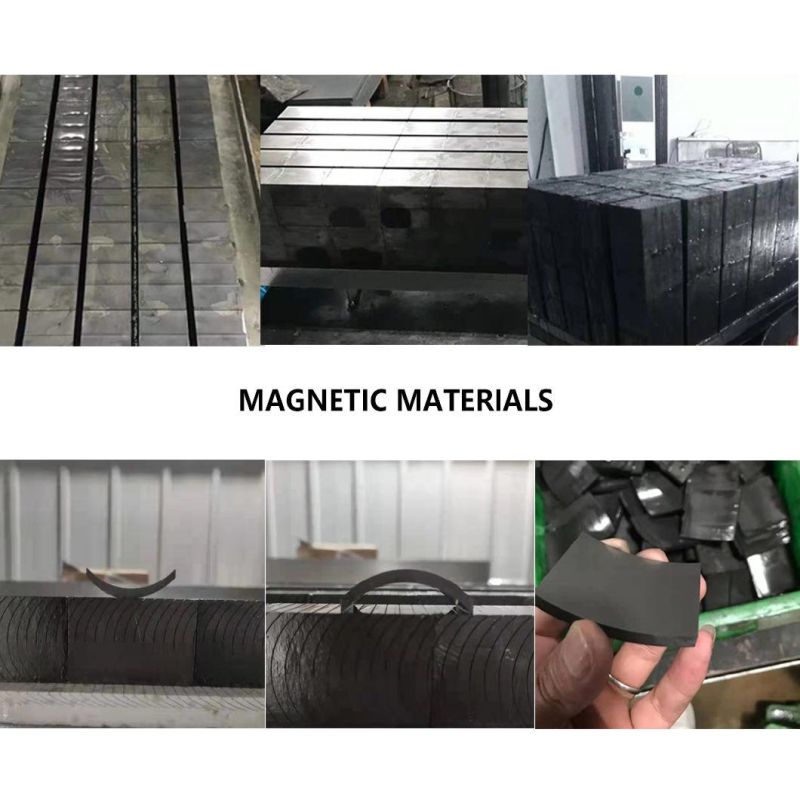

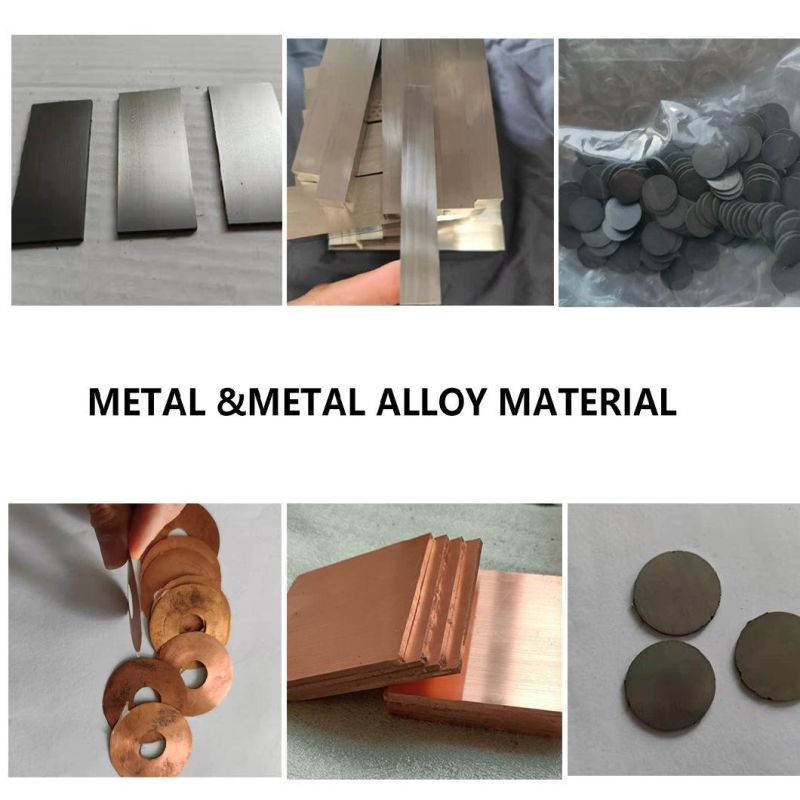

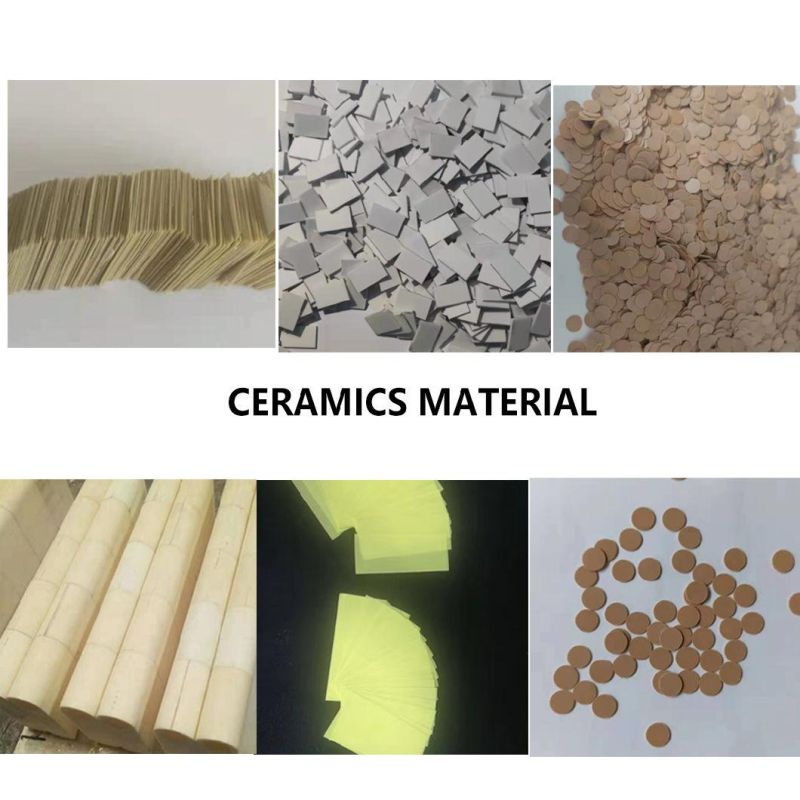

- Application:Magnetic Material

- Type:Multi Wire Sawing Machine

- Maximum Work-Piece Size:300*220*150mm

- Cutting Wire Diameter:Diamond Wire: φ0.12-φ0.20mm

- Cutting Accuracy:Plus - Minus0.01mm

- The Most Thin Slice:0.25mm

=== Base Info ===

- Model NO.:CHTXQ-XZ490

- Worktable Feed Stroke:up to 180mm

- Transport Package:Non Wooden Case

- Specification:length 1800* width 1500* height 1850 (mm)

- Trademark:SUBIT

- Origin:China

- HS Code:8464109000

- Production Capacity:50

=== Description ===

kw

Main functions of CHTXQ-ZX490 multi-wire cutting machine:

1. Rotary tool holder function:

The top roller can be rotated, which changes the running track of the steel wire, reduces the rubbing of the steel wire on the roller groove, improves the service time of the roller and reduces the two jumps when the steel wire passes the top roller, so the cutting accuracy is improved.

Patent No. 2019101085419, 2019201875583, 2019103970784, 2019206822277

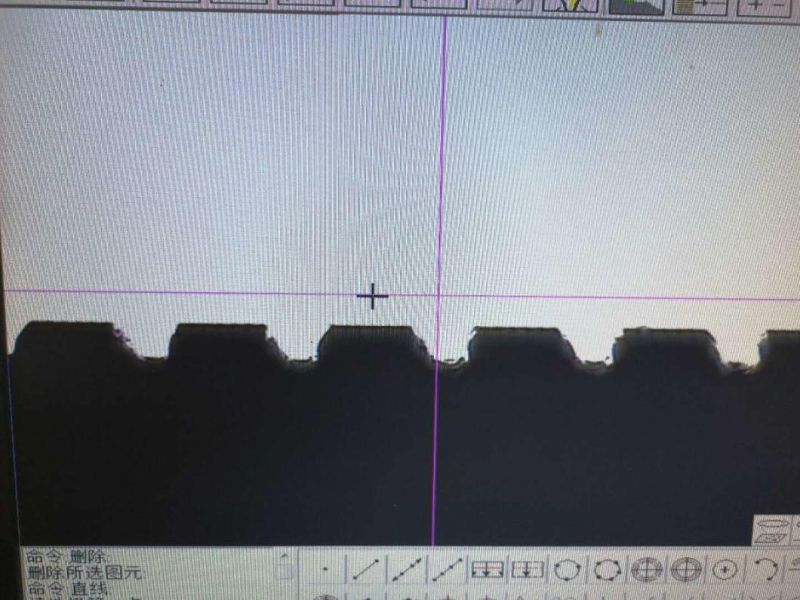

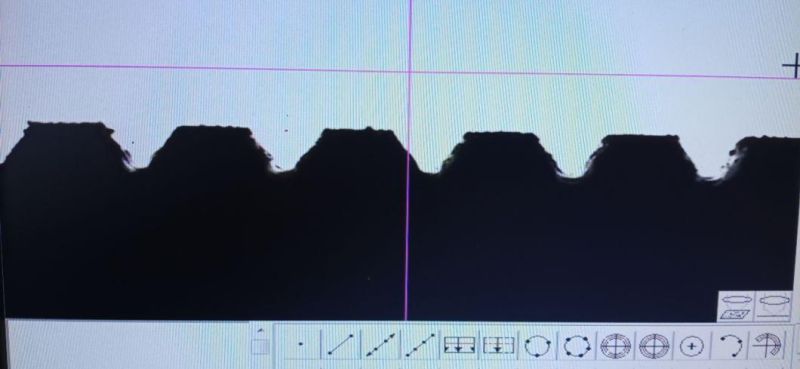

USE EFFECT COMPARISON IMAGES

Image1: Without rotary function

Image2: With rotary function

By using the manufacturer's comparison experiment on the rotation and non-rotation of the tool holder, the same slot distance is 3.2, the service life of the non-rotating roller is 7 days (24 hours of working), and the service life of the rotating roller is 12 days (24 hours of working) ) At the same time, it is found that the steel wire that does not rotate the roller is more likely to be coiled and even broken, the tension is not too large, and the cutting time is 15 minutes longer than that of the rotating roller.

2. Large width winding function:

The winding width of the three rollers can exceed 30mm.

CHTXQ-XZ490 multi-wire cutting machine performance

1. Casting body, so that the overall structure is not deformed, and the high-speed operation is more stable

2. The spindle accuracy is less than or equal to 0.01mm, and it is easy to disassemble and assemble.

3. The lower worktable, the material is cut from the bottom to the top, and the loading and unloading is convenient.

4. The three motors are directly connected to the three rollers, so that all the three rollers become the driving shaft, which reduces the wear of the steel wire on the rollers and improves the service time of the rollers.

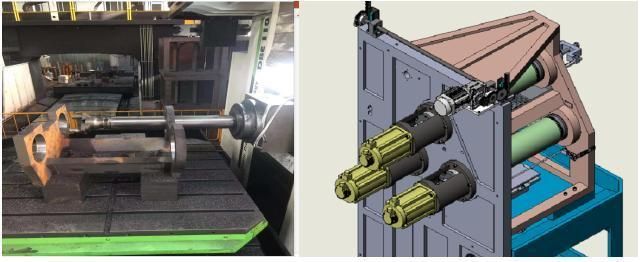

The mounting hole of the roller bracket is processed and formed at one time with a machining center to ensure the coaxiality of the spindle installation.

5. The rotary tool holder adopts a split design, the angle can be adjusted as needed, and the running track of the steel wire can be adjusted to ensure the cutting accuracy.

6. There are few guide wheels, and the guide wheels are reduced to 6

7. Large loading area, respectively: 220mm*490mm*160mm

8. It is easy to operate and use, automatically lift the shield, and the worktable is fully deployed, which is convenient for material loading and unloading and roller loading and unloading.

9. High efficiency and low consumption, the equipment does not need air source, and the power consumption of the whole machine does not exceed 16kw.

CHTXQ-XZ490 multi-wire cutting machine training program

This model is designed to emphasize that people who have never operated a wire cutting machine can immediately operate on the machine after quick training, so all operation buttons, operation handles, and equipment screens are in accordance with the Simple, practical, safe and reliable concept to design and assemble.

lAfter the training courses and other contracts are signed, the equipment enters the factory, and at the production site of your company, we provide customers with training in two aspects:

- Explanation and training of machine operation, troubleshooting, daily maintenance and repair.

- According to the characteristics of the customer's products, train and guide the cutting process for the customer.

Application Case

After sale service:

1)Machine warranty period: within 18 months from the date of installation.

2)Spare parts and components would be provided on free in warranty period but except for the parts broken by mistakingly operation.3)Technical supporting for whole lifetime.4)Any questions will be responded within 24 hours by email, phone call or Whatsapp.

Company Profile

Yutian County changtong Electronics co.LTD was incorporated in 1998,Set up a branch office in 2008 in Yantai. the two companies have a total of 22.000 square meters of land. plant 12.000 square meters registered capital of 10 million yuan, fixed assets of 90 million yuan, headquartered in Tangshan City, Bohai Economic circle. in 2001 the company was recognized as a high-tech enterprise in Hebei Province. in 2014 was named as a science and technology-based small and medium-sized enterprises in Hebei Province, in2016 was recognized as a national high-tech enterprises. In 2017, the company successfully passed the IS09001 international quality management system certification

The company is mainly engaged in multi-line cutting machine equipment, mechanical parts processing quartz crystal frequency chip research and development, design and production, has formed a set oi research and development in use, but also in the use of transformation. three products support each other's mature business model, really from customer demand. in order to create maximum value for customers as the goal, it not only reduces the cost of product development, but also improves the cost-effective product.

Companies continue to increase investment in research and development, in innovation spare no effort, has worked closely with several universities, scientific research units, the use of the advantages oi cooperation between industry and research, to promote industrial innovation, improve product quality. The company's existing "a device for wire cutting processing material placement," two guide wheel multi-line cutting machine and other three invention patents. "a double-loading multi-line cutting machine and other10 utility model technology patents, two software registration rights, a trademark registration right, improve product market competitiveness, the company's production and development of "two guide wheel multi-line cutting machine"

Can be called "the world's smallest guide wheel multi-line cutting machine, in 2017 by the Sino-Tech Enterprise Development Evaluation Center "Certificate of Scientific and Technological Achievements."in order to meet the needs of technology research and development and production, the introduction of CNC gantry milling. CNC processing center, all kinds of CNC processing lathes, microscopes, imaging measuring instruments, and other advanced equipment at home and abroad, the use of technology research and development. production capacity and other aspects of close cooperation with the United States AB,Taida.Huichuan,etc

Products quartz crystal frequency tablet HC-49S. SMD has accumulated production and sales of more than 6 billion pieces. supporting Japan KDS, as well as Indonesia, South Korea, Taiwan and other domestic companies, is China's piezoelectric industry crystal materials well-known brands.

Company history

- 1998 Established in Yutian county.Research and development, design and production of quartz crystal frequency chips

- 2001 Awarded High-Tech enterprise of Hebei Province.

- 2008 Set up a branch office in Yantan city,passed the IS09001 international quality management system certification.

- 2014 Ranked as a science and technology small and medium-sized enterprise in Hebei Province

- 2016 Awarded National High Tech enterprise.

- 2017 Self-invented multi-wire cutting machine with minimum guide wheel.

- 2018 Self-R&D wire saw process center,Set up a machining workshop.

- 2019 Independent R&D of the world's first wire saw machining center.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23