Automatic Corn Flakes Puff Snacks Core Filling Inflating Cheese Ball Making Machine

QINGDAO BAIXI INDUSTRY CO., LTD. / 2022-07-04

- After-sales Service:Best Services

- Warranty:12 Months

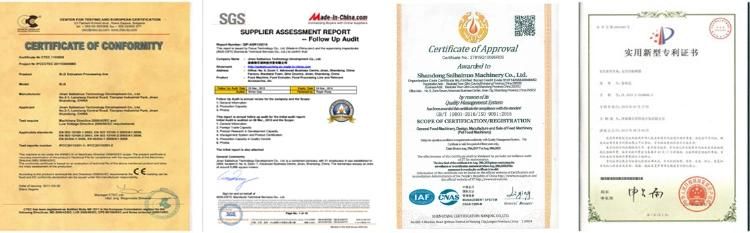

- Certification:CE, ISO9001, BV

- Power Source:Electric

- Process:Concentration and Dry

- Automatic Grade:Automatic

=== Base Info ===

- Model NO.:SLG65,70,85

- Application:Popcorn, Chips, Biscuit, Corn Flakes, Breakfast Cereals,Bugles,Corn Chips

- Customized:Customized

- Motor Brand:Siemens or ABB

- Raw Materials:Corn Flour, Rice Flour or Other

- Machine Material:Stainless Steel 304

- Capacity:100kg,H~150kg,H. 200kg,H~250kg,H,400kg,H~500kg,H

- Transport Package:Wooden Case

- Specification:CE

- Trademark:SBN

- Origin:Jinan Shangdong China

- HS Code:8438800000

- Production Capacity:100kg,Hr~600kg,Hr

=== Description === 1. Series of Twin-screw Extruder mainly consist of feeding system, extruding system, cutting system,heating system, lubricating system and controlling system.

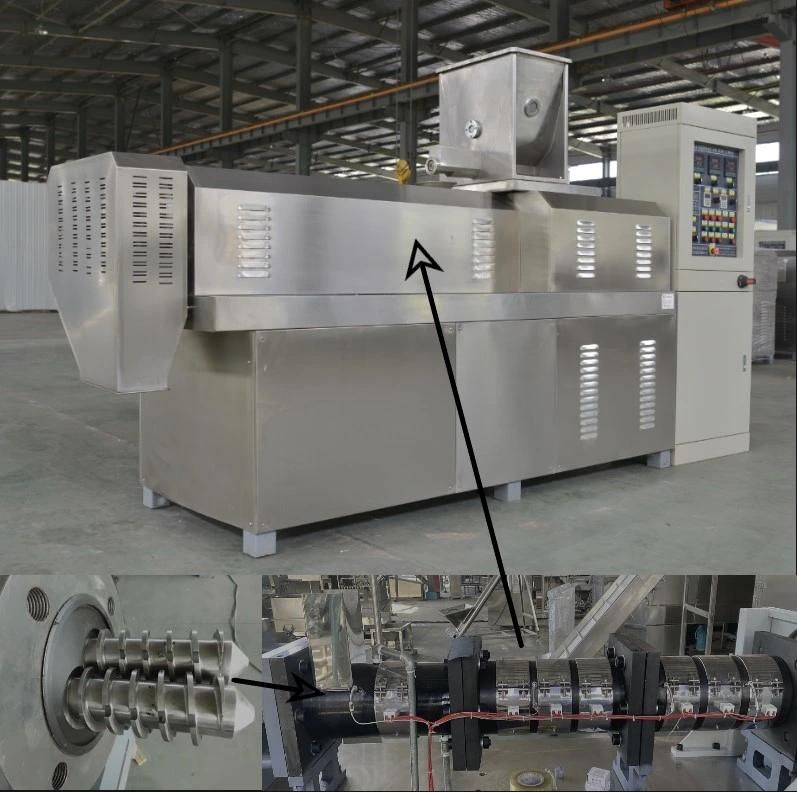

1. Series of Twin-screw Extruder mainly consist of feeding system, extruding system, cutting system,heating system, lubricating system and controlling system.

2. Automatic lubricating and forced cooling make sure that extruder performs safely and extends using life.

3. Feeding system,extruding system and cutting system all adopt frequency conversion timing to gain powerful drive, stable perform, and electricity saving.

4. Screws are made of alloy and processed bu special technique to possess high intensity, abrasion resistant resistant and longer using life.

5. By means of designing different structures and slenderness ratios according to needs of products, screw extruding system can meet different technology demands.

6.According Twin-screw extruder machine, we develop some processing line:Puff snacks,core filling Processing Line.

Corn Flakes,Breakfast Cereals Processing Line,Crispy Chips,Sala,Bugles Processing Line , Bread Crumb Processing Line.etc.

The main processing line

Cheese Ball ,Puff Snacks Core filling processing line This process line is a new type of extruding food machine studied and developed by ourselves on the basis of learning from advanced technology in the world so that its technical performance and quality of products both reach to the most advanced in the world.This line will finish mixing,extruding,shaping,core-filling,cutting,spraying and producing in one-pass operation automatically.This line features lots of types,flexible collocation,extensive applied materials,various products and easy operation.

This process line is a new type of extruding food machine studied and developed by ourselves on the basis of learning from advanced technology in the world so that its technical performance and quality of products both reach to the most advanced in the world.This line will finish mixing,extruding,shaping,core-filling,cutting,spraying and producing in one-pass operation automatically.This line features lots of types,flexible collocation,extensive applied materials,various products and easy operation.

Food symbol

Technical Parameter

Machine Picture

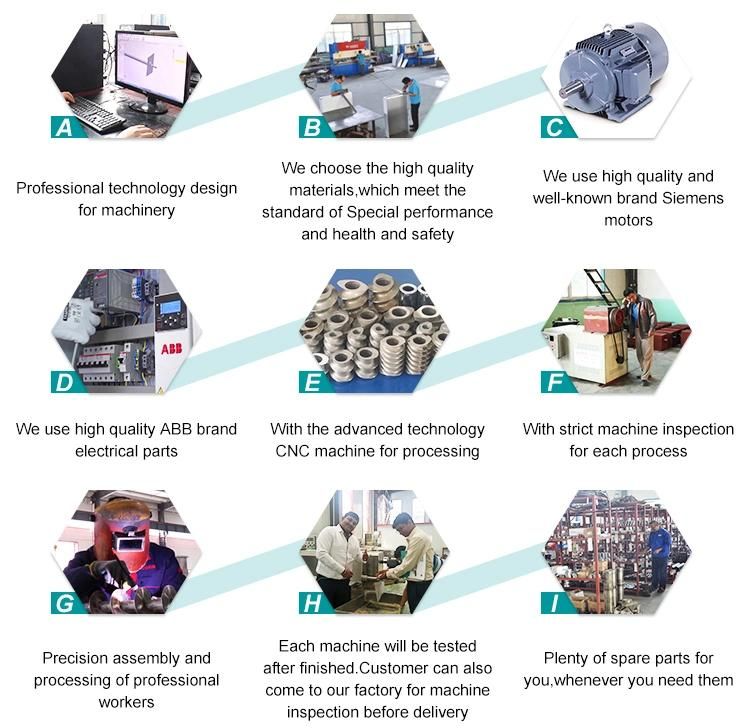

Equipment Strength

Work shop

Work shop

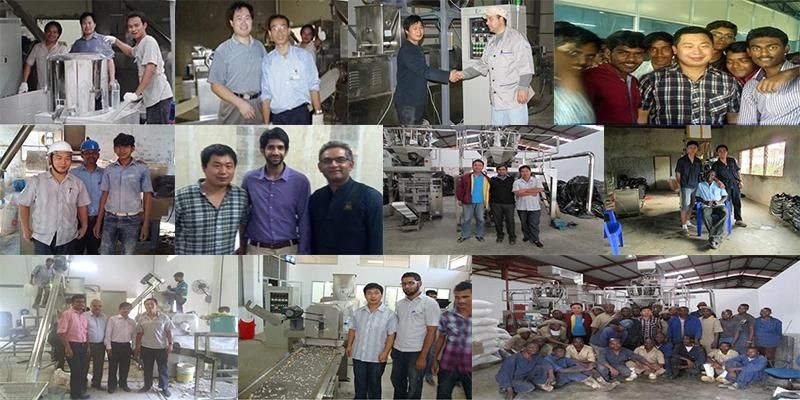

After-sales Service

Company qualification

Jinan Saibainuo Technology Development Co,.Ltd is a professional food &feed machine manufacturer. With our many years' research and study, snack machine have been widely used in many fields. We can also provide special designing puff mini snack machine according to clients' special requirements. Free formula, local installation, workshop design, machine inspection service are provided, any need will be met if inquiries.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23