Wood Plastic Composite Doors Board Panel Making Machine Production Line PVC WPC Door Frame ...

Ningbo Easyget Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

electromagnetismInstall power 95kw 120kw

3,Wood Plastic Mixer

SHR series Plastic mixer is suitable for mixing,drying and coloring PVC/WPC etc material.

ModelModel SRL200/500 SRL-300/600 SRL-500/1000 SRL-800/1600 SRL-1000/2000 Total volume 200/500 300/600 500/1000 800/1600 1000/2000 Effective volume 120/300 180/360 300/600 480/1000 600/1200 Mixing time 8-15min 8-15min 8-15min 8-15min 8-15min Cooling time 10-15min 10-15min 10-15min 12-18min 12-18 Hot mixer motor power 30/42kw 40/55kw 47-67kw 90KW 110kw

4,WPC door making processing machines

This WPC door manufacturing process machine is used for making WPC door panels from PVC and wood powder, the WPC hollow panel can be used either inner and outer door panel, partition, windowsill etc.it centralizes the characters of both plastic and wood, and also overcomes the shortage of wood, such as water -proof, corrosion resisting, anti-moth, anti-aging, static-free, and flame retarded.

PVC door panel making machine UPVC door sheet machine WPC door production line

This WPC PVC door production line is applicable to the continuous extruding of WPC/PVC door panel, clapboard 'elbow board. Proper double screw extruder, specially used for extruding wood plastic products, should be chosen in accordance with the panel section, application, and product specific gravity. Also the corresponding auxiliary machines such as vacuum calibrating platform, hauling off machine, cutting off machine, material reversing platform,etc. are equipped. Products of diversified specification can be produced with different dies.

Relate machines

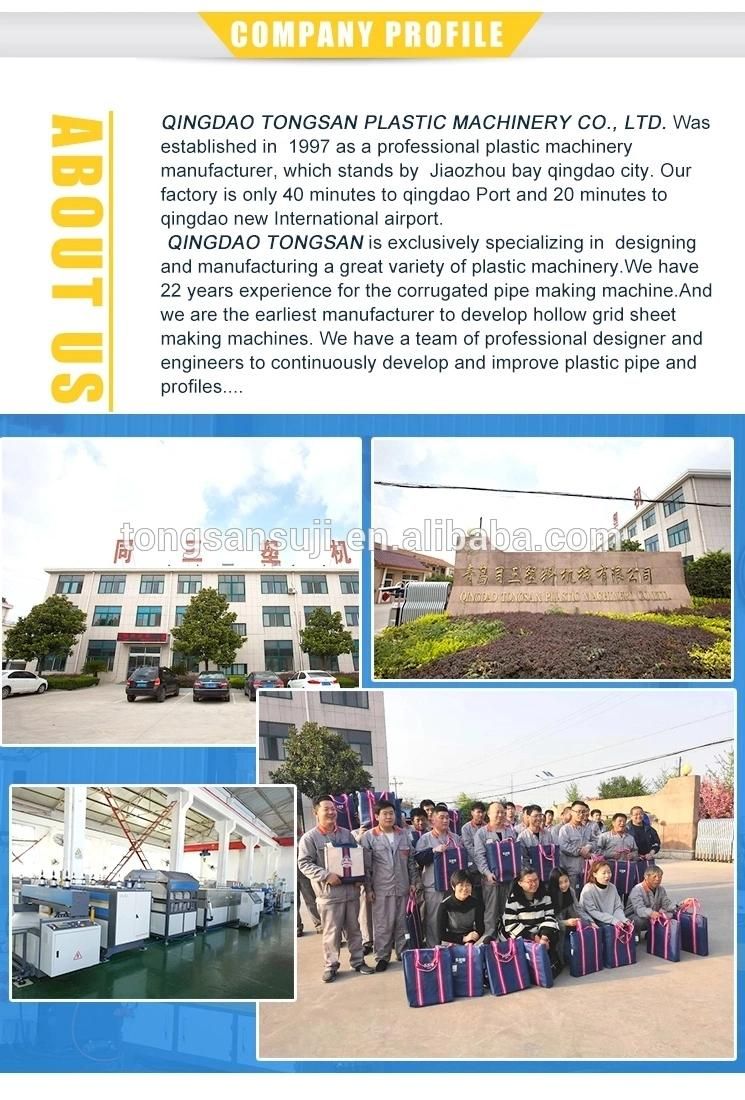

Qingdao Tongsan Plastic Macxhinery CO.,LTD is professional for the Whole WPC production line with turnkey Project Service since 1997.We have all the WPC machines in factory stock and can be tested at anytime.

We have different type of WPC machines to make different WPC products from different raw material,

1, PVC WPC profile machine:

Material: 50%PVC+20% wood+20% caco3+ Chemical additives.

Product: WPC door frame, WPC wall panel, WPC decoration profiles indoor.

2, PVC WPC door machine:

Material:50% PVC+20% wood+20% caco3 +Chemical additives.

Product: Hollow Door panel, Cabinet Door, and other big profiles

3, PVC WPC board machine:

Material: 60% PVC+10% wood +20% CaCo3+ Chemical additives.

Product: Solid door panel, Furniture board, partition wall panel, decoration solid panel.

Model SJMSB-80/156 SJMSB-80/173 SJMSB-92/188 Board thickness 5-18mm 3-30mm 20-40mm Board width 1220mm 1220mm 1220mm Max extrusion capacity 350-380kg/h 420-450kg/h 500-550kg/h Motor power 75kw 90kw 110kw

4, PP PE WPC granulating machiner

Material: recycled 30% PP/PE+70% wood powder+chemical additives.

Product: WPC decking, WPC wall cladding, WPC fence, WPC pergola..Model L/D ratio Max.capacity Motor power Suitable material Max.rotating speed Wood powder percentage SHMS-65 40:1 200-220kg/h 75kw Pe+wood powder 500r/min ≤75% SHMS-75 40:1 300-350kg/h 90kw Pe+wood powder 500r/min ≤75% SHMS-90 40:1 500-600kg/h 132kw Pe+wood powder 500r/min ≤75%

5,PP PE WPC profiles machine

HGMSE series PP/PE WPC profile production line can continuously produce PP/PE WPC profile. The WPC profile adopts two -step production process. The granulating machine make WPC pellets using PP/PE recycled materials, wood powder and auxiliary agent. Then use this production line produce WPC profile.Customers can choose embossing machine for the production line to achieve 3D pattern performance.Customers can also make PE WPC single color or double color co-extrusion profile by adding extruders.The profile produced by this production line can be sanded and brushed by sanding machine and brushing machine.

Model HGMSE-65 HGMSE-80 Extruder model SJMS65/132 SJMS 80/156 Motor power 37kw 75kw Mac.Extrusion capacity 140-160kg/h 220-250kg/h Co-extruder(Optional) SJ35/28 SJ45/28

Be Our Client:

Why Choose Us?

FAQ:

More questions please send the massage to me.^-^

Looking for hear from you.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23