330 Moulds Chocolate Bar Making Machine Production Line Chocolate Moulding Line

Gd Julong Electric Co., Ltd. / 2022-07-05

- Certification:CE

- Power Source:Electric

- Process:Cocoa Bean Processing Machinery

- Automatic Grade:Automatic

- Application:Peanut

- Customized:Customized

=== Base Info ===

- Model NO.:LFM

- Transport Package:Wooden Packing

- Specification:customized

- Trademark:Longer

- Origin:China

- Production Capacity:100-1000kg,H

=== Description ===

Basic Info.

Model NO. LFM Transport Package Wooden Packing Specification customized Trademark Longer Origin China Production Capacity 100-1000kg/HProduct Description

Introduction of Chocolate Moulding Line

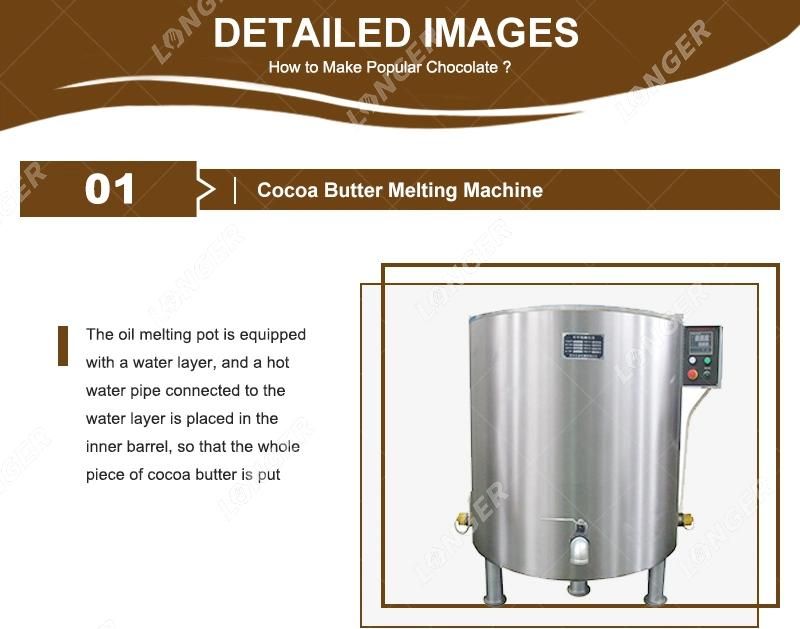

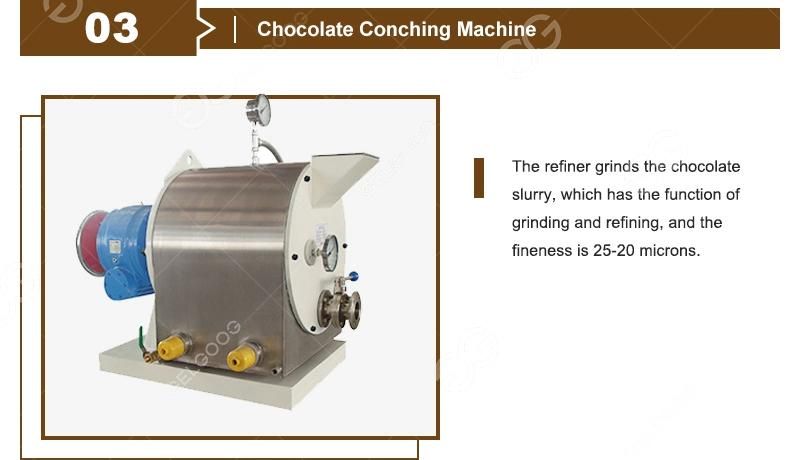

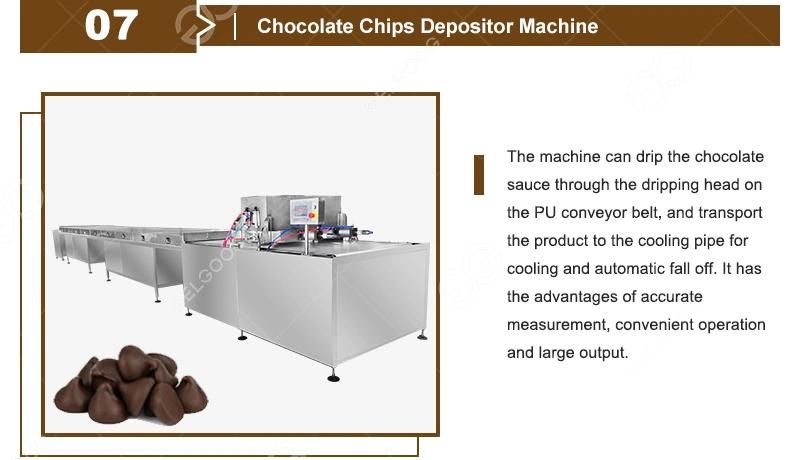

1.The chocolate moulding line includes cocoa butter melting machine, cocoa powder grinding machine, conching and refining machine,storage and heating machine, tempering machine, chocolate chip depositing machine, chocolate packing machine and so on.

2.Chocolate bunch type packing machine is mainly used for packing chocolate peanuts with diameter less than 35mm and in hemispherical shaped, heart-shaped, cube-shaped.

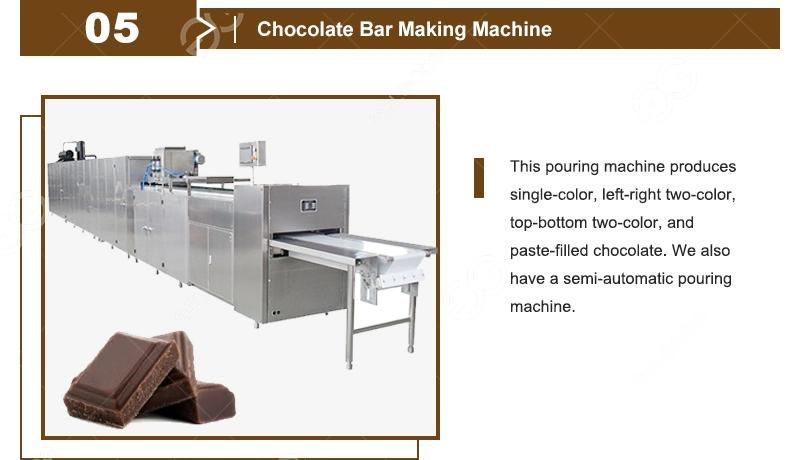

.3.This chocolate moulding line series can be used to produce single flavor, two flavors, triple flavors, pastes central filling, nuts central filling, and other kinds of chocolates according to different configurations of the machines. This series has two major machine types; semi- automatic and fully automatic and its configurations can be customized according to production needs.

Parameters Of Chocolate Line Productio

| 1:Cocoa Fat Melting Tank | Material:Stainless Steel Capacity:600L Pump power:0.2KW Electric heating power:6KW Dimension:2000×1000×900mm |

| 2:Sugar Grinding Machine | Capacity:250kg/h Total Power:9KW Dimension:1100×750×1800mm |

| 3: Chocolate grinding machine | Capacity:1000L Main motor power:22KW Regulating motor power:1.5KW Electric heating power:6KW Dimension:2970×1320×1790mm |

| 4: Chocolate storage tank | Material:Stainless Steel Capacity:1000L Main motor power:2.2KW Electric heating power:4KW Dimension:1220×1850mm Net weight:1000kg |

| 5: Continuous chocolate tempering machine | Capacity:250L/h Total power:7.1KW Dimension:1130×880×1910m Net weight:580kg |

| 6: Chocolate moulding machine | Capacity:50-150kg/h Temperature of cooling tunnel:5-10ºC Cooling time:18-30min Quantity of mould:280×200×30mm Net weight:2500kg Dimension:11000×1000×1800mm |

| 7: Chocolate pump | Material:Stainless Steel Dimension:780×390×350mm Net weight:120kg |

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23