Tex77 High Torque Milling Spline Extruder Shaft

Hebei Dechuang Chemical Equipment Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Imported Material

WR Material

Domestic Material

1.Made in Germany

2.Made in Janpan

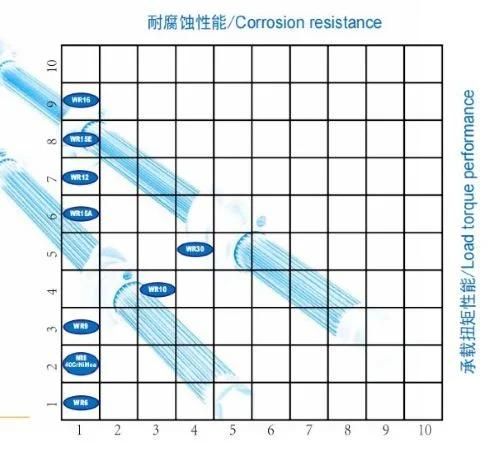

WR6 WR12 WR8 WR9 WR15A WR15E WR10 WR30

40CrNiMo is a kind of alloy constructional steel.

a. WR9 with special treatment and involute form can be used under the circumstances of high torque, high torsion andhigh load. b. Nitrogen bearing Martensite stainless steel ,WR15E and WR30 can also be applied to make good toughnessand machine performance available. The performance parameters similar to the imported shaft but with more costefficient, the machining process is under accurate controlling to make sure the accuracy of groove depth anddistance, the smoothness of the surface, toughness and durability as well.

4. Torque of spline shaft

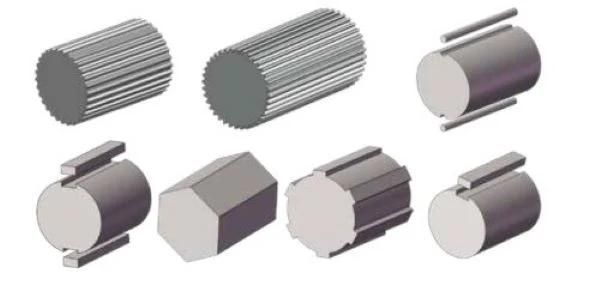

5. Types of shaft to choose:

Single keyway

Square keyslot

High torque key button

Dual keyslot

Involute inner spline

Round keyslot

Rectangle spline

Client requirements available

6. Our factory is state-of-the art and spans over 20,000 square meters. The factory houses more than 130 sets of different domestic and foreign high precision production equipment, with the degree of numerical control up to 95%.

All shafts must be ajusted by hydraulic straightening machine.

7. Packaging:

According to your order quantities and products sizes to choose the number of wooden boxes.

a. Rust-proof oil processing,

b. Oiled paper packages,

c. Bubble wrap package,

d. Special foam packaging,

e. Packing,

f. Sealing.

8. Why choose us?

(1) Total solution of highly wear-resistance and corrosion-resistance problems;

(2) Expert of engineering design and consulting,

(3) Advanced manufacturing capabilities and technology,

(4) Lean production management

(5) Top quality products with high cost performance

9. FAQ:

1.Q: Are you trading company or manufacturer?

A: We are factory.

2.Q: Where is your factory located? How can I visit there?

A: Our factory is located in Chengdu, Sichuan Province, China, 1) You can fly to Chengdu Airport directly. We will pick you up when you arrive in the airport; All our clients from domestic or abroad are warmly welcome to visit us.

3.Q: What makes you different with others?

A: Our Excellent Service For a quick, no hassle quote just send email to us we promise to reply with a price within 24 hours - sometimes even within the hour. If you need an advice, just call our export office at +86 19150954315, we will answer your questions immediately. 2) Our quick manufacturing time For Normal orders, we will promise to produce within40 working days. As a manufacturer, we can ensure the delivery time according to the formal contract.

4. Q: What is your terms of payment ?

A: 1) T/T 2) L/C;

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23