New Design Milk Dairy Processing Machinery for Turn Key Project

NINGBO HAISHU JUDIN PACKING PRODUCTS CO., LTD. / 2022-07-05

- Process:Thermal Processing

- Power Source:Electric

- Certification:CE, ISO9001

- Automatic Grade:Automatic

- Application:Milk, Yogurt, Milk Powder, Cheese

- Customized:Customized

=== Base Info ===

- Model NO.:KQ Series

- Name:New Design Milk Dairy Processing Machinery for Tur

- Applications:Milk ,Yogurt,Cheese ,Ice Cream Plant

- Material:Stainless Steel 304 ,316

- Capacity:100L-15000L,Hour

- Type:Turn Key Project

- Milk Packing:Tera Package ,Plastic Bag , Bottle

- Motor:ABB,Siemens ,China Brand

- Voltage ,Hz,Phase:Make Them Based on Your Order

- Warranty:One Year or Two Years

- Pipe Fittings:Available

- After-Sales Service:Yes

- Working Life:More Than 10 Years

- Install and Adjustment:Available

- OEM/Customized:Yes

- Milk Life:6 Days ,90-180 Days

- Transport Package:Wooden Box

- Specification:300L------15000L,Hour

- Trademark:Kaiquan

- Origin:China

- HS Code:8479820090

- Production Capacity:50 Lines , Year

=== Description ===

Basic Info.

Model NO. KQ Series Name New Design Milk Dairy Processing Machinery for Tur Applications Milk ,Yogurt,Cheese ,Ice Cream Plant Material Stainless Steel 304 /316 Capacity 100L-15000L/Hour Type Turn Key Project Milk Packing Tera Package ,Plastic Bag / Bottle Motor ABB/Siemens /China Brand Voltage ,Hz,Phase Make Them Based on Your Order Warranty One Year or Two Years Pipe Fittings Available After-Sales Service Yes Working Life More Than 10 Years Install and Adjustment Available OEM/Customized Yes Milk Life 6 Days ,90-180 Days Transport Package Wooden Box Specification 300L------15000L/Hour Trademark Kaiquan Origin China HS Code 8479820090 Production Capacity 50 Lines / YearProduct Description

New Design Milk Dairy Processing Machinery For Turn Key Project1. Introduction :

Product Application

This milk production line capacity is 1T/H-20T/H, it can produce several types of flavored pasteurized milk products, i.e. whole milk, skimmed milk and standardized milk of various fat contents, meanwhile with options to produce yogurt, cheese, cream and butter etc.This milk production line raw milk can be fresh milk or powder milk or both, this small milk production line milk normally stored at low temperature about 4-5 degree, which can maintain the nutrition at maximum.

End product package of this small milk processing line can be plastic pouches, plastic cups, plastic bottles, glass bottles, roof top box etc. For this dairy production line according to different end product and package type, the production technology is differently designed but commonly include the following steps.

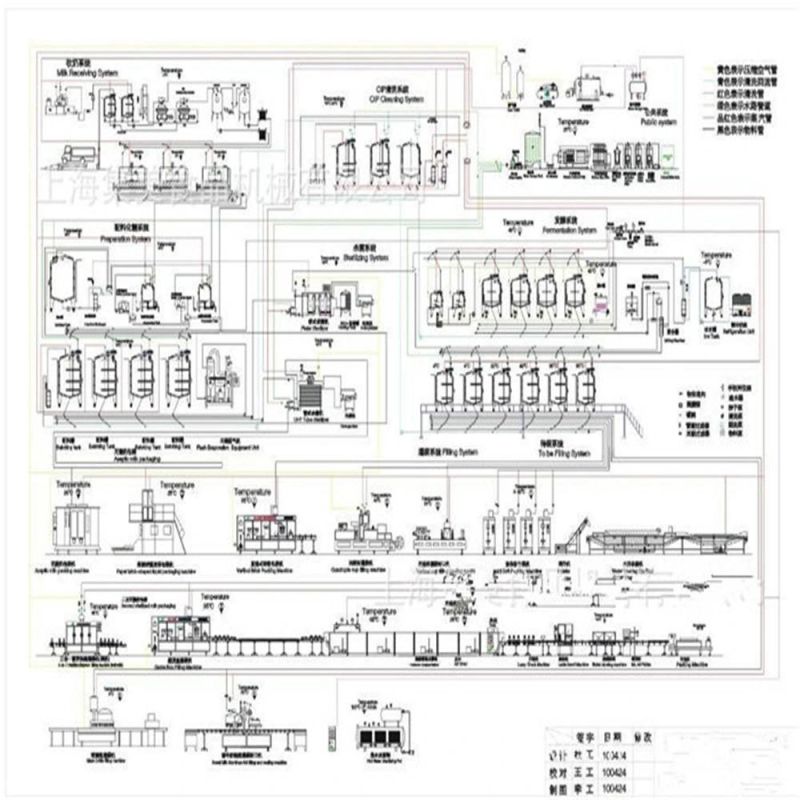

The whole milk production line including the following machines:1.Water treatment system.

This part including water filter and reverse osmosis puriffication system for pure water.

2.Water supplying system.

This part including constant pressure system,electric control system,water storage tank.

3.Milk collection system.

This part including the milk receiving tank,milk separator,filter,flowmeter,etc.

4.Mixing system.

This part including the plate heat exchanger,water-powder mixer,mixing tank,emulsifying tank.

5.Sterilization system.

This part including plate type sterilizer,high pressure homogenizer,300s warm holding tank.

6.Fermentation system.

This part including the seed tank,fermentation tank.

7.Filling system.

If your package is carton,this part including cup filling machine.

If your package is bottle,this part including bottle filling machine,auto sleeve labeling machine,inkjet printer

8.Low air compressed system

This part including the air compressor,air filter,air dryer,air storage tank.

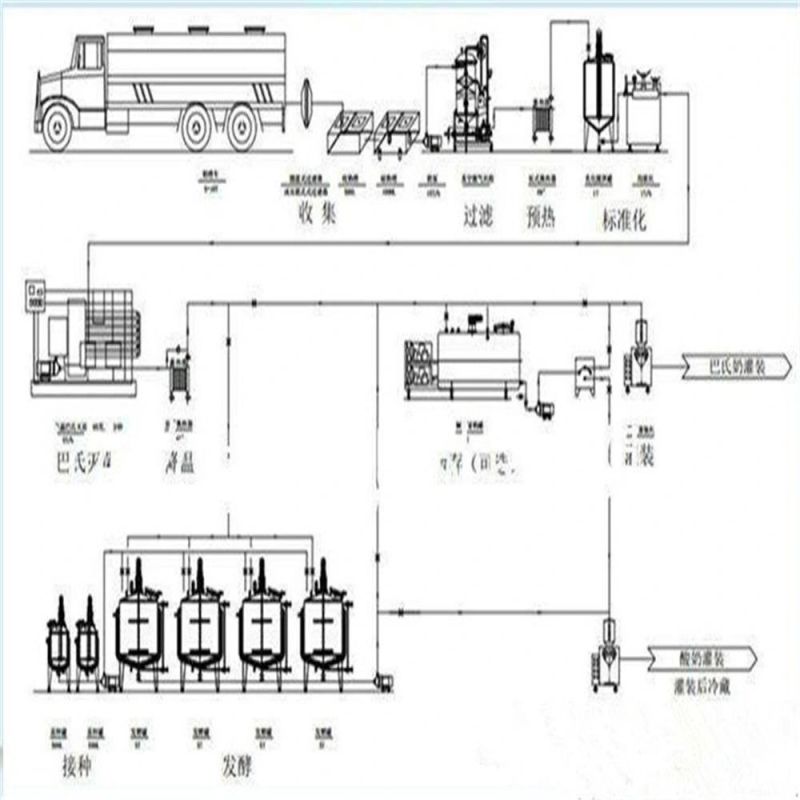

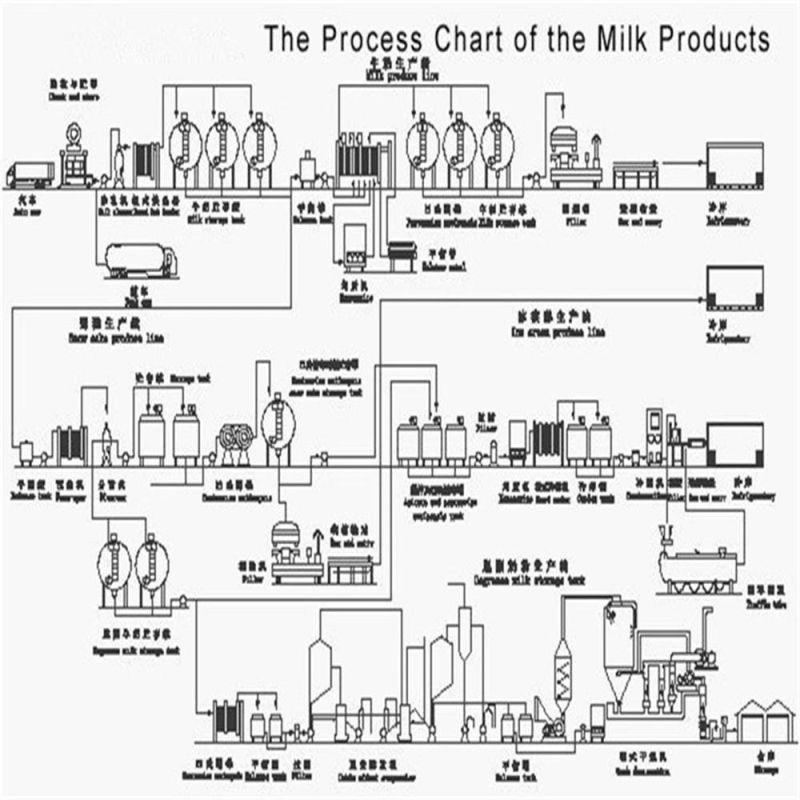

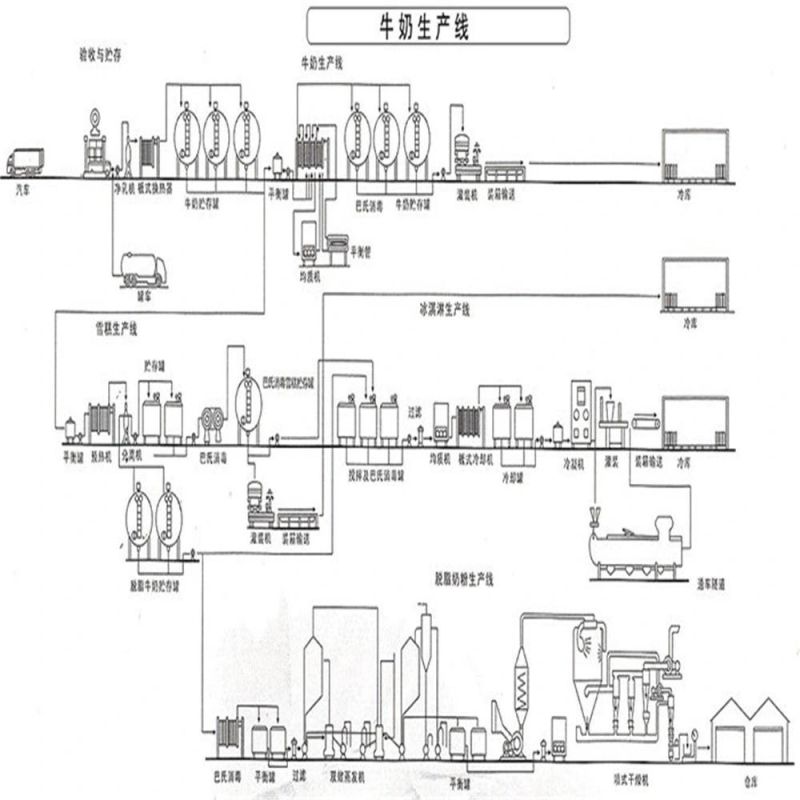

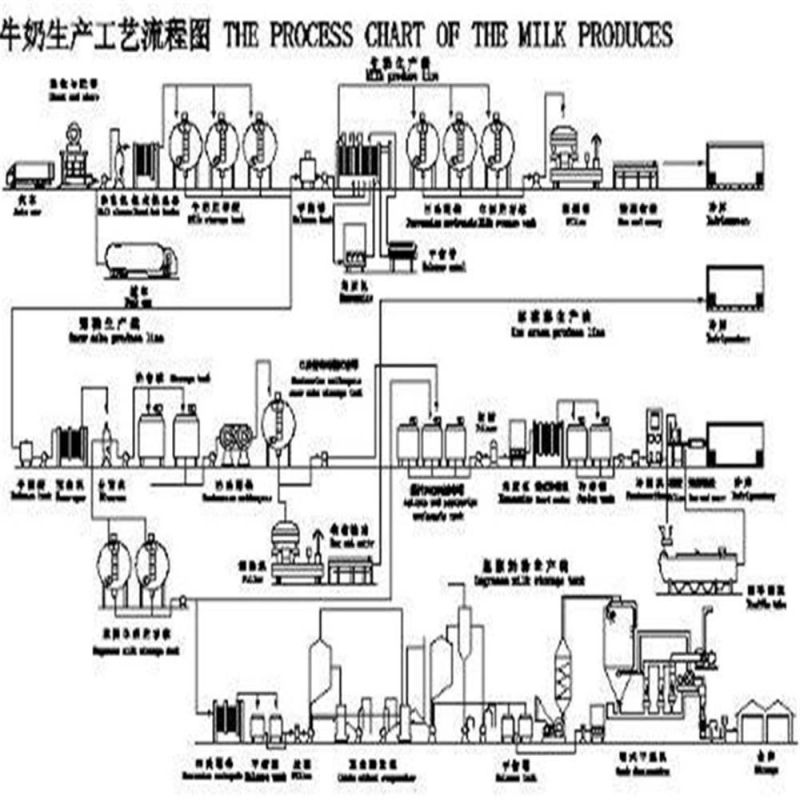

2. Milk Plant Drawing :

New Design Milk Dairy Processing Machinery For Turn Key Project

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23