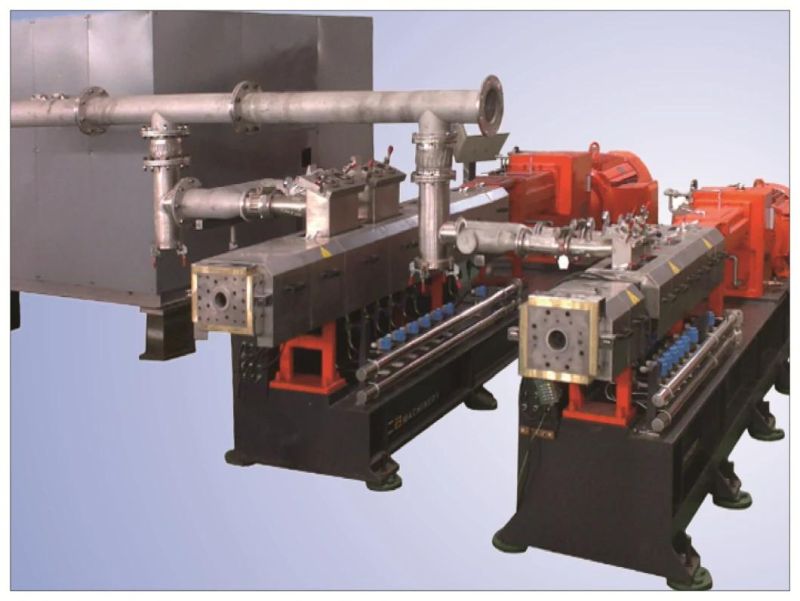

Jwell Twin Screw Dryer-Free Vented Pet Sheet Extrusion Machine with Ce Certification

Jiangsu YiCheng Fluid Equipment Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

product introductionThe double screw dry-free exhaust PET sheet production line launched by Changzhou Jinwei has the characteristics of low energy consumption, simple process and convenient maintenance of equipment. Its unique screw combination structure effectively reduces the viscosity of PET resin, symmetrical thin-walled roller improves cooling efficiency, productivity and sheet quality, multi-component feeding device reasonably controls the proportion of new material, recycling, color masterbatch, etc. The sheet produced by the device can be used in the fields of plastic absorption, printing and packaging.

JWELL company Jwell machinery was established in 1997. As the vice president unit of CPMIA, Jwell Machinery is one of the largest manufacturers of plastic extrusion machinery in China. The production bases of Jwell company are consisted with 5 parts, which are located in Jiading district of Shanghai , Zhoushan City of Zhejiang Province, Taicang City and Liyang City of Jiangsu Province and Dongguan City of Guangdong Province with total area nearly 1000mu(about 67 hectares). Company head office locates in Shanghai Jiading. Nowaday, we has about 3000 employees with about 480 technical and management staff. We supply more than 2000 set of advanced plastic extrusion line and chemical fiber spinning equipment every year.

Company has independent intellectual property rights system with nearly 400 authorized patents including 35 invention patents. NATIONAL HIGH AND NEW TECHNOLOGY ENTERPRISE, SHANGHAI FAMOUS BRAND, NATIONAL KEY NEW PRODUCT and other honors have been continuously awarded to Jwell since 2010.

Certification

CertificationISO:9001

CE certification of extruder

CE line-auxiliary equipments

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23