Turbo Vacuum Mixer with Cosmetic Agitator /Stainless Steel Liquid Mixing Tank/Vessel

Yuyao Jingdu Sprayer Co., Ltd. / 2022-07-04

- Certification:CE, ISO9001

- Power Source:Electric

- Process:Thermal Processing

- Warranty:One Year After Commissioning

- After-sales Service:Yes

- Automatic Grade:Automatic

=== Base Info ===

- Transport Package:Strong Seaworthy Wooden Cases

- Power:7.5kw-45kw

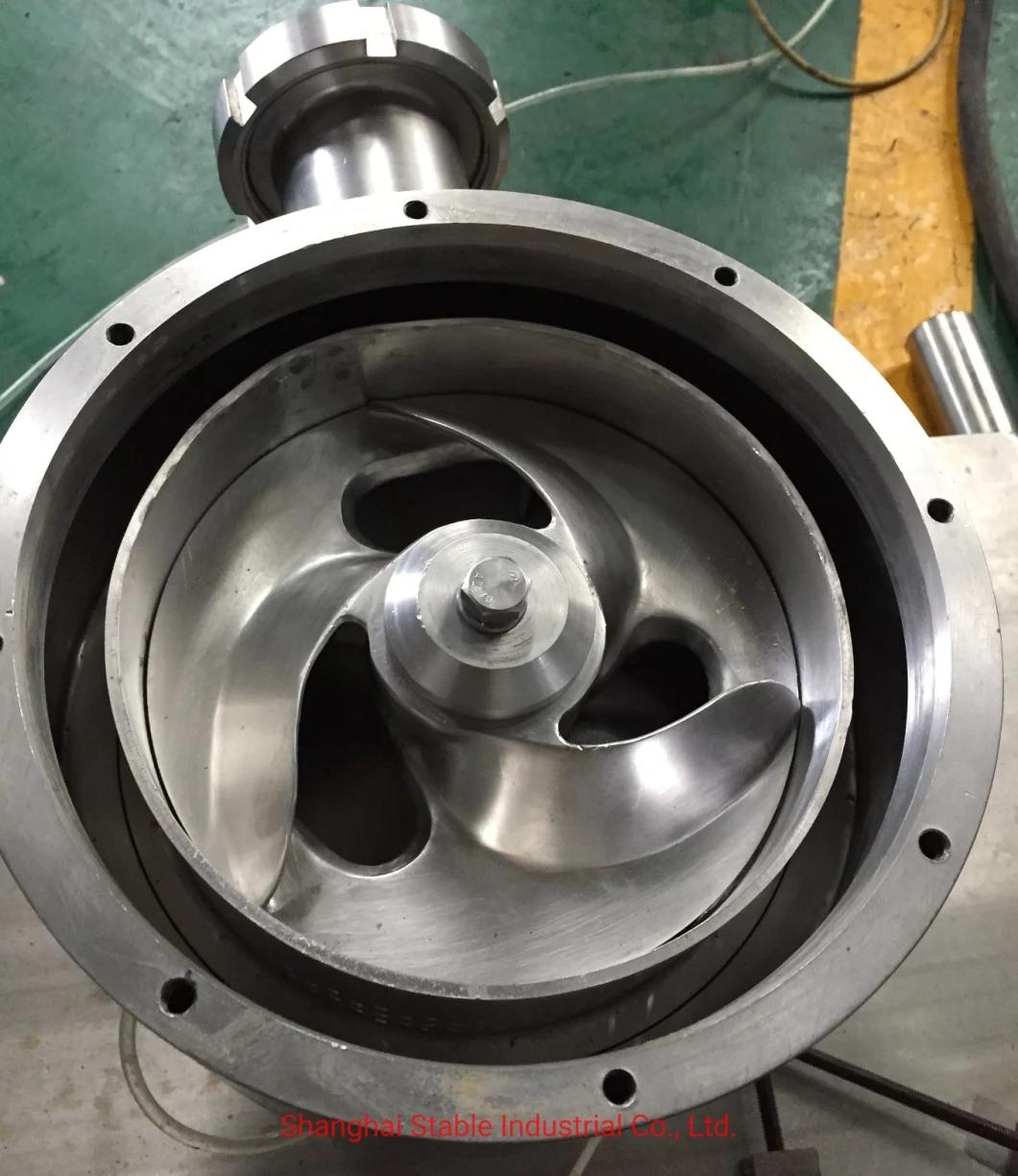

- Function:High Shear, Mixing

- Name:Vacuum Mixer,Blender

- Capacity:5000L,H-400000L,H

- Customized:Customized

- Application:Milk, Yogurt, Milk Powder, Cheese

- Model NO.:STB-tank

- Specification:can be customized

- Trademark:STB

- Origin:Shanghai

- HS Code:8438200000

- Production Capacity:5sets,Month

=== Description ===

PVA ,dyestuff, detergent, ceramics, Ferrite, various chemical goods

- Foods

Cheese products, ice cream, liquid foods, baby foods, dressings, seasonings

- Pharmaceutics

Chinese medicines, digestive medicine, inhalation, Filler and coating for tablets

- Cosmetics

Beauty creams, facial cleansing creams

Direct steam injection

Outlet

Stators of various design specification

Knife / propeller

Funnel

Insulation

Agitator / stirrer with scraper

Automatic valve system

Operation monitoring system

PLC control system

Explosion - proof design

Advantage

- No dusting

Since powder materials are fed to Turbo Mixer below liquid level under the vacuum, no dusting during the powder charging process.

- No foaming

Vacuum condition in the Turbo Mixer prevents the foaming during the mixing process. Therefore, this allows to produces de-aerated product.

- Reduced mixing time

Liquid and powder materials are efficiently brought into contact and it resulting in significantly reduced mixing time.

- All-in-one mixing process

Products / ingredients can be dissolved, dispersed, homogenized and cooled / heated.

- Available for high viscous products or materials with high solid content (up to 80%).

- It offers accurate mixing, dispersion and emulsification.

- It can be used with existing processes without any modification.

- Automatic processes are also available.

- Sanitary execution.

- It can be equipped with a scraper and CIP system

The unit is normally supplied according to the requirements of the food industry. The unit is made in AISI 316, Ra ≤0,8 μm on all surfaces in contact with product and other surfaces in AISI 304.Other surfaces and materials are available on request.The tank is normally constructed for 100% vacuum and certified pressure vessels are available up on request. For the food industry the machines can be supplied as a sterile mixer with sterile barriers.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23