Pet Plastic Recycling Washing Machine Used for Dealing with Waste Pet/HDPE Bottle

Taizhou Shangzheng Hydraulic Tools Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. PET-500; PET-1000; PET-1500; PET-2000 Control PLC Contactor Schneider Frequency Changer ABB Final Product Clean Pet Falkes Capacity 300-2000kg/H Machine Color Optional Transport Package Plastic Film and Wooden Case Specification PET-500 Trademark sevenstars Origin China HS Code 84778000 Production Capacity Depend on The Customer ′s Special RequirementProduct Description

Pet Plastic Recycling Washing Machine Used for Dealingwith Waste Pet/HDPE Bottle

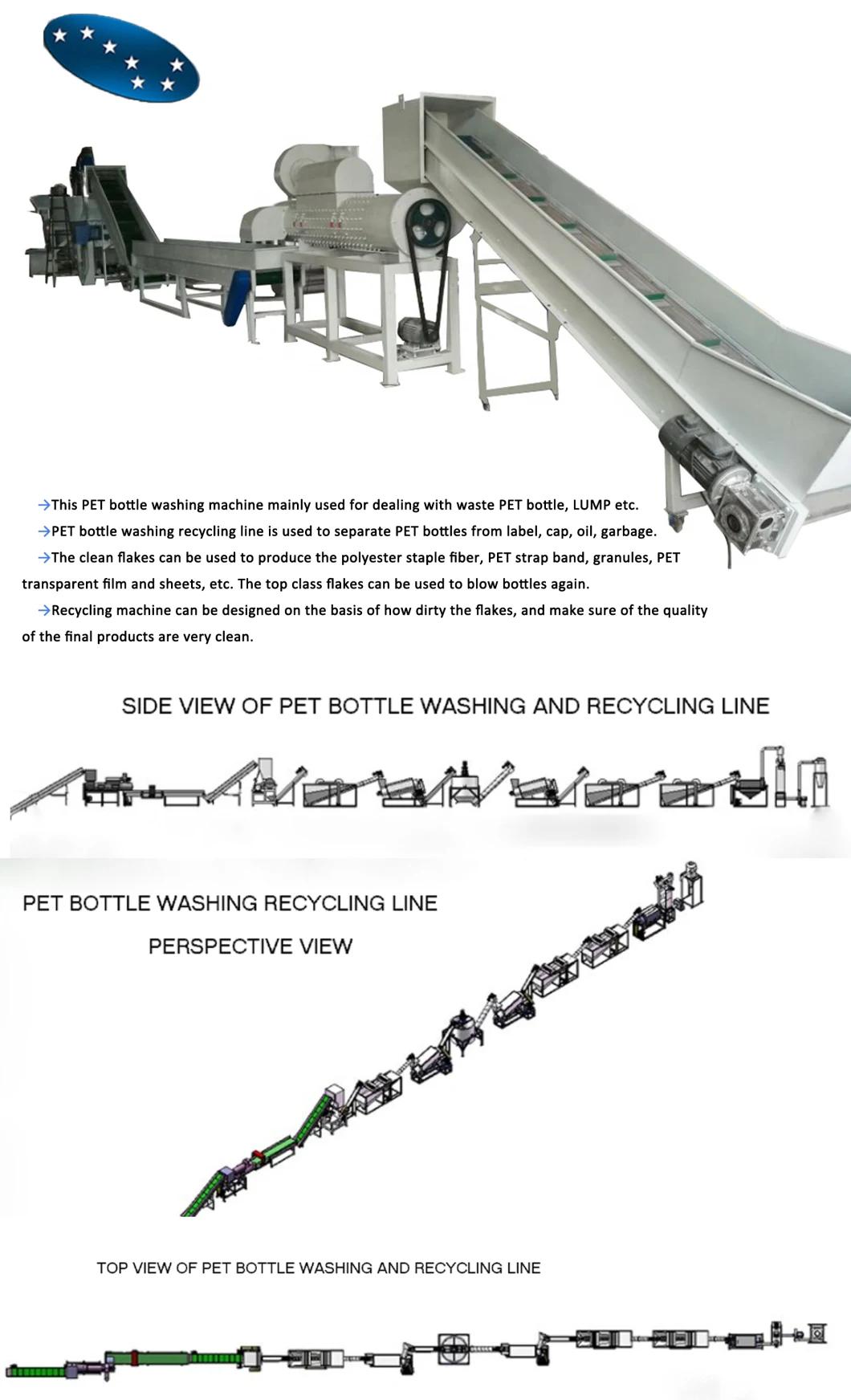

This PET bottle scrap washing line mainly used for dealing with waste PET bottle, HDPE Bottle, LUMP, PP barrel etc.

To separate PET bottles to flakes from PE/ PP label, cap, oil, garbage, protect the environment, avoid white pollution.

This PET bottle washing machine is composed of separator, crusher, cold & hot washing system, dewatering, drying, packing system, etc.

This PET bottle flakes crushing, recycling and washing production line can easily wash and recycle waste PET bottle flakes. Waste and dirty PET bottle flakes can be treated step by step by this facility. It is special for washing PET bottles flakes. We can help to attach equipment at the end of the washing line so that the completely dry flakes can be collected and packed directly after be washed.

Work flow of plastic bottle recycling machine

Conveying raw material--Crushing with water-- Feeding --No. 1 Rising washer--Feeding --Agitating washer--Feeding--Horizontal frication washer --No. 2 Rising washer --Feeding--No. 3 Rising Washer--Feeding--Dewater machine--Pump conveying system--Hopper

| Input capacity | 500kg/h | 1000 kg/h | 2000 kg/h |

| Workshop(M*M*M) | 42 (L)×10(W)×6(H) | 55(L)×15(W)×6(H) | 70(L)×18(W)×6(H) |

| Ancillary staff | 6Persons | 8 Persons | 12 Persons |

| Installation power | 156KW | 307KW | 420KW |

| Water Consumption: | 2Ton/h | 3.5Ton/h | 5 Ton/h |

| Final product | Moisture: max 1% Bulk density: 0.3G/CM 3 Particle size: 14-18mm Metal content: max.20ppm Floatable contamination: less than 200ppm Total impurity: 100-320ppm | Moisture: max 1% Bulk density: 0.3G/CM 3 Particle size: 14-18mm Metal content: max. 20oom Floatable contamination: less than 200ppm Total impurity: 100-320ppm | Moisture: max 1% Bulk density: 0.3G/CM 3 Particle size: 14-18mm Metal content: Max. 20ppm Floatable contamination: less than 200ppm Total impurity: 100-320ppm |

Zhangjiagang sevenstars is located in Zhangjiagang city, China, a beautiful and famous city for all kinds of plastic machine.

We have 17000 square meters land and new modern workshop, we mainly development, design, manufacture and marketing plastic pelletizing machine, plastic recycling machine, pet bottle recycling machine, PVC pipe making machine, PE pipe making machine, PVC foam board production line, plastic granulator, plastic shredder, plastic pulverizer, Plastic agglomerator, single shaft shredder, double shaft shredder, plastic crusher and so on. By the several years developing, we grown up to a middle scale company in China plastic industry.

As one of the reliable supplier in China, We have keeping improved our management and technology level. Up to now, we have earned good reputation in domestic and abroad market. And our products have been exported to many countries, like mexico, America, Argentina, Chile, Brazil, Russia and so on.

Quality and honest is our foundation, customer satisfactory is our job, to get "Win-Win" is our main targe. We always focus on improving our quality. And we have buit up a professional after-sale services team with rich-experienced in machine commissioning and installation. We believe our quality and service will bring success to each customer.

Welcome final users and distributors from all the world contact with us and create success.

With your support and our effort, we deeply believe that the tomorrow of sevenstar will be much better.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23