Double Piston Self-Cleaning Backflush Melt Filter /Screen Changer with 4 Screen Cavities ...

Quanzhou Easy Light Stone Tools Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Over all dimension

Heating power

(KW))

Output

(kg/h)

Sippment and service

Optional choice

Adpters

support stands

down stream equipments: suach as Gmach melt gear pump

filter mesh/screen

vacuum cleaning furnace

Tips for customers

How to choose a most suitable type of screen changer for your extrusion line ?

After the equipment supplier making a size recommendation and then you should perform your own analysis to confirm appropriate sizing. That way, you will have the advantage of independent analyses and, best of all, there is no additional cost.

Learn the difference between price and cost. Be sure to take into consideration all of the variables and look at all the factors to determine the real cost of ownership for the screen changer. Some of the hidden variables to consider may be:

Product quality.

Maintenance, time and cost of parts.

Process downtime and cost.

Life expectancy for the equipment and amortized cost of ownership.

Cost and availability of filtration media.

Pressure loss and effect on line output and product quality.

Operator safety.

Required operator intervention and labor cost.

If all of these and other factors are taken into consideration, you can choose the most suitable solution, and then you can expect a much better return on investment.

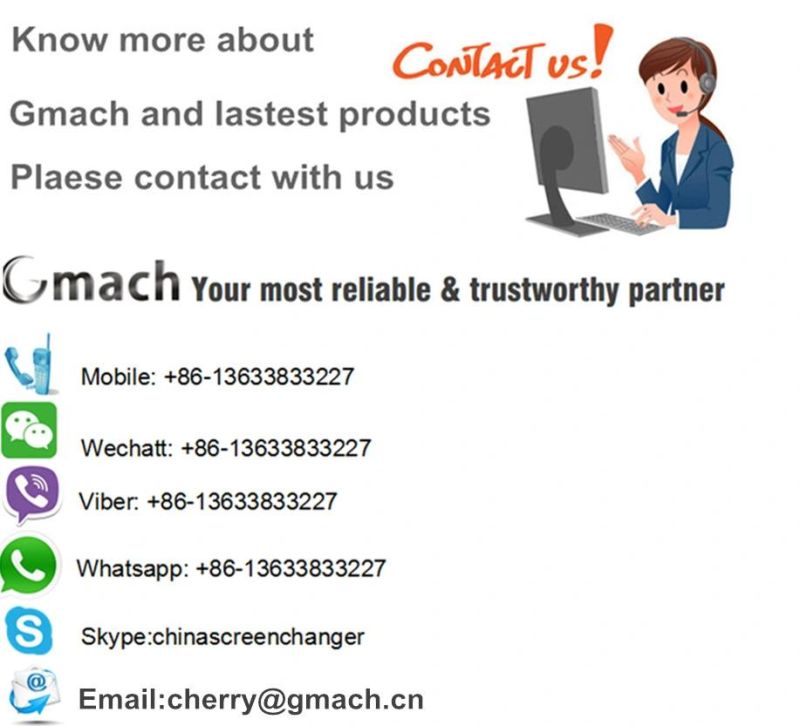

Details information , please contact with us

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23