Pet Bottles Waste Plastic Recycling Crushing Washing Machine

Fujian Nanan Xin Pulifei Diamond Tools Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. 500-3000kg/h Computerized Computerized Certification ISO9001:2008, CE Recycling Machine Output 500-3000kg Machine Pet Bottles Plastic Recycling Crushing Washing Mac Material Pet Bottles Control Cabniet PLC Final Flakes Moisture < 0.9% Total Impurity < 80 Ppm Washing Chemical Can Offer Formula Flakes Packing 500kg/1000kg Ton Bag Flakes Size 10-18mm(Customizable) Voltage Customizable Transport Package Wood Base and Wood Case Specification 500-3000kg/h Trademark DEEDO Origin Jiangsu, Chian HS Code 84778000 Production Capacity 5 Lines Per MonthProduct Description

PET Bottles plastic recycling crushing Washing Machine1.This line output: 500kg/h-4000kg/h

2. PLC control

3. Machine material for high-quality 304 stainless steel; Ensure no second pollution to flakes.

4. Purity

a) Specifications Normal: Polyester staple fibers, Stripes purity: < 200ppm

b)High-quality: Food-containers, POY-yarn, PET sheets purity: < 100ppm

c)Perfect: bottle to Bottle, Granulation purity: < 50ppm Flake Quality Reference - Food Grade

5. Moisture : < 0.9%

PET Bottle Wash Line,

PET plastic bottle washing line,

PET Plastic flake produce line

Description:

The Process is used to recycle 500kg/h-4000kg/h capacity and stable quality raw material, especially for PSF manufacturer and recycled POY manufacturer with big capacity.

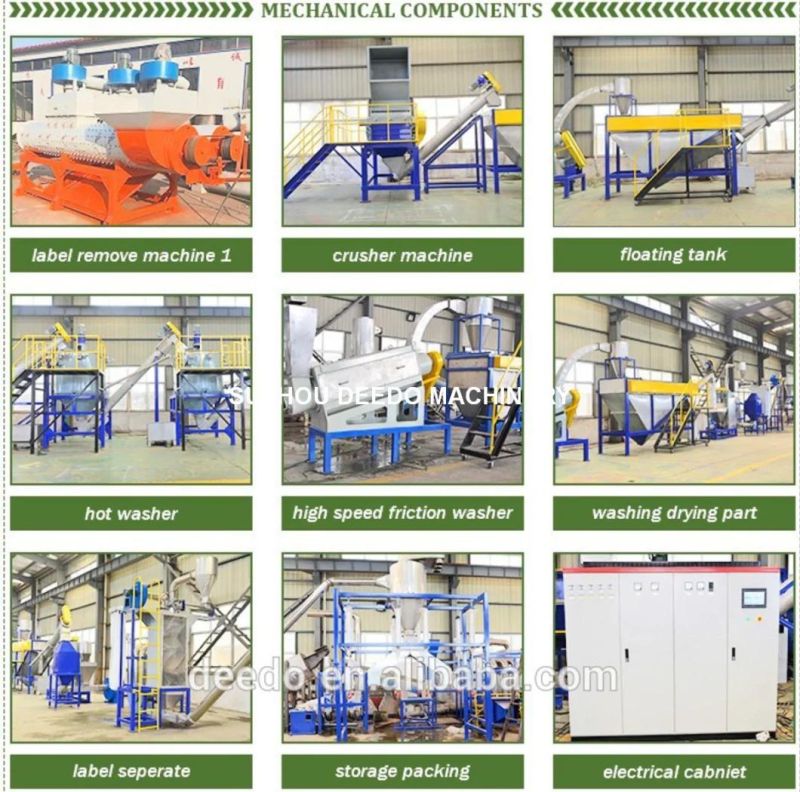

Process Flowchart:

De-baling----- Label Scrapping------ Label Separation------- Bottle Pre-washing--------Manual Sorting and Metal Detecting-----Wet Grinding-------Gravity Separation-------Chemical Washing for PET Flakes-------Rinsing--------Drying--------Packing

Composition of PET Bottle Bale:

| Description | Recycling machinery |

| PET Containers | One-way bottles |

| Colors Fraction | PET bottles should be pre-sorted by color. If the percentage of color bottles is higher than 30%, we suggest customer to install the automatic color bottle sorting machine to achieve efficiency. |

| Base Cups | Included, if any, and should be PP or PE plastic. |

| Labels (shrunk or glued) | The production line is designed for removing label mechanically. All type of labels will be removed by mechanical action. It includes paper, BOPP, PET, PVC, etc. |

| Caps | PP, HDPE |

| Caps seals | EVA, PP ( floatable material ) PVC or rubber seals are not separable. |

| Glue | Hot melt, water borne. |

| Contamination | Mixed with the bottles could be present contaminations coming from the collection and storage of the postconsumer bottles or made by consumer. These contaminations include mud, sand, soil, glass, organics, paper, residual liquid, etc. Total contamination content should not exceed 10%. |

| Total Non-PET Containers | Non-PET containers max 2% of which |

| PVC Container | 0.5 -1% max |

| Polyolefins Container | 3 % max. It will only affect the output volume but not quality of end product. |

| Wrong PET Colors and Opaque | 1-2% max |

| Glass and Ceramic (metals excluded) | 0.5 -1% max |

| Magnetic Metals | 0.5 - 1% max |

| Aluminum and Non Magnetic Metals | 0.5 - 1% max All kind of metal will be separated before crushing |

If u want to know more details ,pls fell free to contact with us

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23