600kg Large Scale Industrial Vacuum Lyophilizer Machine Freeze Dryer

Shenzhen Fango Technology Co., Ltd. / 2022-07-05

- Type:Dryer

- Voltage:380V

=== Base Info ===

- Model NO.:GZL-60

- Power:130kw

- Customized:Customized

- Product Name:600kg Large Scale Industrial Vacuum Lyophilizer Ma

- Model:Gzl-60 Freeze Dryer

- Freeze Dried Area:60 M2

- Capacity:600 Kg

- Shelf Dimensions:1500*2000 mm

- Ice Collecting Capacity (Kg/Batch):1200 Kg,Batch

- Heating Method:Electric Heating

- Ultimate Vacuum:<5 PA

- Cold Trap Temperature (°c):-75

- Defrosting Mode:Spraying + Soaking

- Dimension(L*W*H):9000*2400*4500 mm

- Certification:CE

- Key Selling Points:High Safety Level

- Material:SUS304

- Cooling Mode:Water Cooling

- Transport Package:Plywood Case Package

- Specification:9000*2400*4500mm

- Trademark:LABOAO

- Origin:China

- HS Code:8419399090

- Production Capacity:10 Set,Month

=== Description ===

Basic Info.

Model NO. GZL-60 Power 130kw Customized Customized Product Name 600kg Large Scale Industrial Vacuum Lyophilizer Ma Model Gzl-60 Freeze Dryer Freeze Dried Area 60 M2 Capacity 600 Kg Shelf Dimensions 1500*2000 mm Ice Collecting Capacity (Kg/Batch) 1200 Kg/Batch Heating Method Electric Heating Ultimate Vacuum <5 PA Cold Trap Temperature (°c) -75 Defrosting Mode Spraying + Soaking Dimension(L*W*H) 9000*2400*4500 mm Certification CE Key Selling Points High Safety Level Material SUS304 Cooling Mode Water Cooling Transport Package Plywood Case Package Specification 9000*2400*4500mm Trademark LABOAO Origin China HS Code 8419399090 Production Capacity 10 Set/MonthProduct Description

600KG Large Scale Industrial Vacuum Lyophilizer Machine Freeze DryerFreeze dryer is widely used in medicine, pharmacy, biology research, chemical industry and food production ,etc. After the freeze

drying process, a long term preservation for products is much easier. They can be restored to the original state and maintain their

chemical and biological characteristics after being watered.Feature1. The clapboard is made of professional technology, with high pressure resistance, high flatness and good temperature uniformity.

2. High-efficiency mixed refrigerant medium, low freezing point and high boiling point, high heat exchange efficiency.

3. The drying curve optimization control algorithm can control the product heating rate and vacuum value during the drying stage.

4. Professional gas diversion design and control technology, strong water catching capacity and high drying efficiency.

5. During the drying operation, the vacuum degree is adjusted to avoid foaming and blowing of special substances and improve the

drying efficiency.

6. Industrial-grade embedded touch screen + dedicated SH-HPSC-IV modular controller, the system is stable and reliable, and the

control accuracy is high.

7. The professionally designed LYO-CONTROL control system can save multiple sets of process recipes, and can adjust the

process in real time during the drying process to improve the process optimization rate.

8. Flexible manual + automatic control mode, manual for exploring the process, automatically for mass production.

9. User level and password can be set, decentralized operation management.

10. Optional powerful LYO-MEGA host computer control system, which can record and save operating data, curves and alarm

records for up to ten years to improve the traceability of the product; at the same time, it is convenient for observation, operation

and fault diagnosis.

11. Non-standard customization can be made according to user needs.

Specification

Specification| Model | GZL-60 |

| Drying area (m2) | 60 |

| Input capacity (10mm thickness) (L) | 600 |

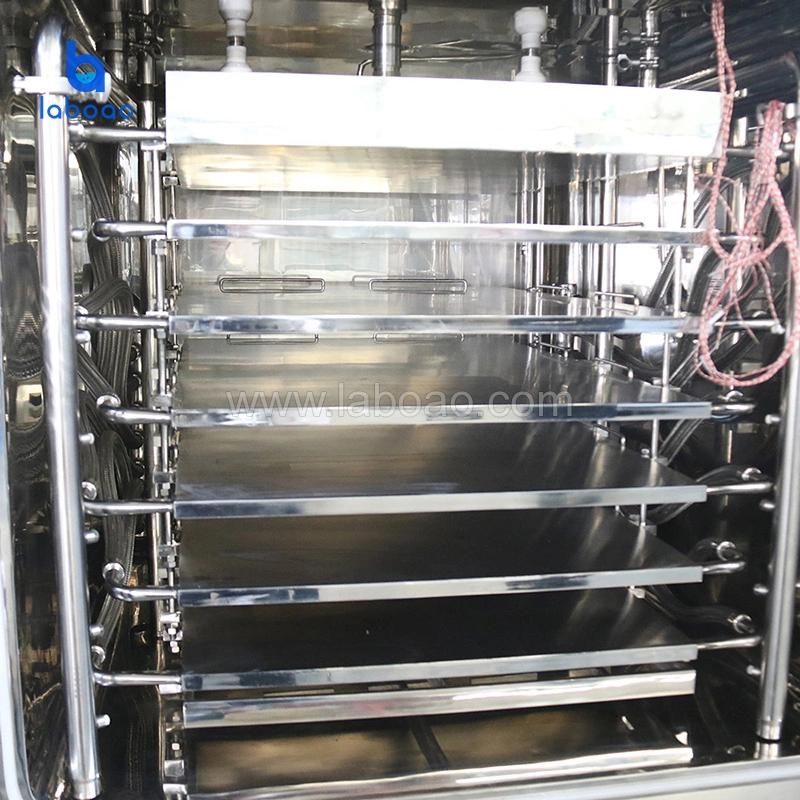

| Shelf number (Layers) | 20+1 |

| Shelf size (mm) | 1500*2000 |

| Shelf space (mm) | 80 |

| Temperature range (°C) | -50~+80 |

| Water vapor condensation (Kg/D) | ≥1200 |

| Cold trap temperature (°C) | ≤-75 |

| Cooling mode | Water cooling |

| Defrost mode | Water immersion |

| Vacuum (Pa) | ≤5 |

| Power (KW) | 210 |

| Size (L*W*H) (mm) | 9000*2400*4500 |

| Weight (kg) | 30000 |

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23