Cold Press Peanut Oil Production Line

Shenzhen Xiangfeizhu Technology Co., Ltd. / 2022-07-05

- Type:Oil Equipment

- Application:Vegetable Seed

- Voltage:220V

- Appearance:Vertical

- Press Materials:Peanut

- Press Series:First

=== Base Info ===

- Model NO.:Huatai -peanut

- Condition:New

- Customized:Customized

- Capacity:10tpd-1000tpd

- Transport Package:Bulk

- Specification:Specific

- Trademark:no

- Origin:China

- HS Code:84792000

=== Description ===

MODEL

Capacity ..

Overall Dia.

(mm)

Weigh

t(Kg)

Motor

(Kw)

6YL-80A

100kg/h

1420*635*1480 &1135*530*520

680

5.5+0.55

6YL-95A

150kg/h

2270*1100*1950

780

7.5+1.1

6YL-120A

250kg/h

2202*1285*2220

880

11-15

6YL-130A

500kg/h

2302*1585*2820

1280

15+2.2

6YL-160A

800kg/h

2502**1680*2900

1350

22+2.2

The oil yield ratio of oil press

Oil Materials

Oil Extraction Rate%

Residue

Oil Quality

Consumption

Oil of Cake

Hot Press

%

Impurity

Water

Acid

KW.H/T

%

%

Value%

Peanut

≥91

≤8.0/6.0

≤0.20

≤0.20

≤0.40

≤35.0

Rapeseed

≥80/85

≤8.0/7.0

≤0.20

≤0.20

≤0.40

≤35.0

Soybean

≥65/70

≤7.0/6.0

≤0.20

≤0.20

≤0.40

≤52.0

Cottonseed

≥75/82

≤7.5/6.0

≤0.20

≤0.20

≤0.40

≤55.0

Sesame

≥91

≤8.0

≤0.20

≤0.20

≤0.40

≤35.0

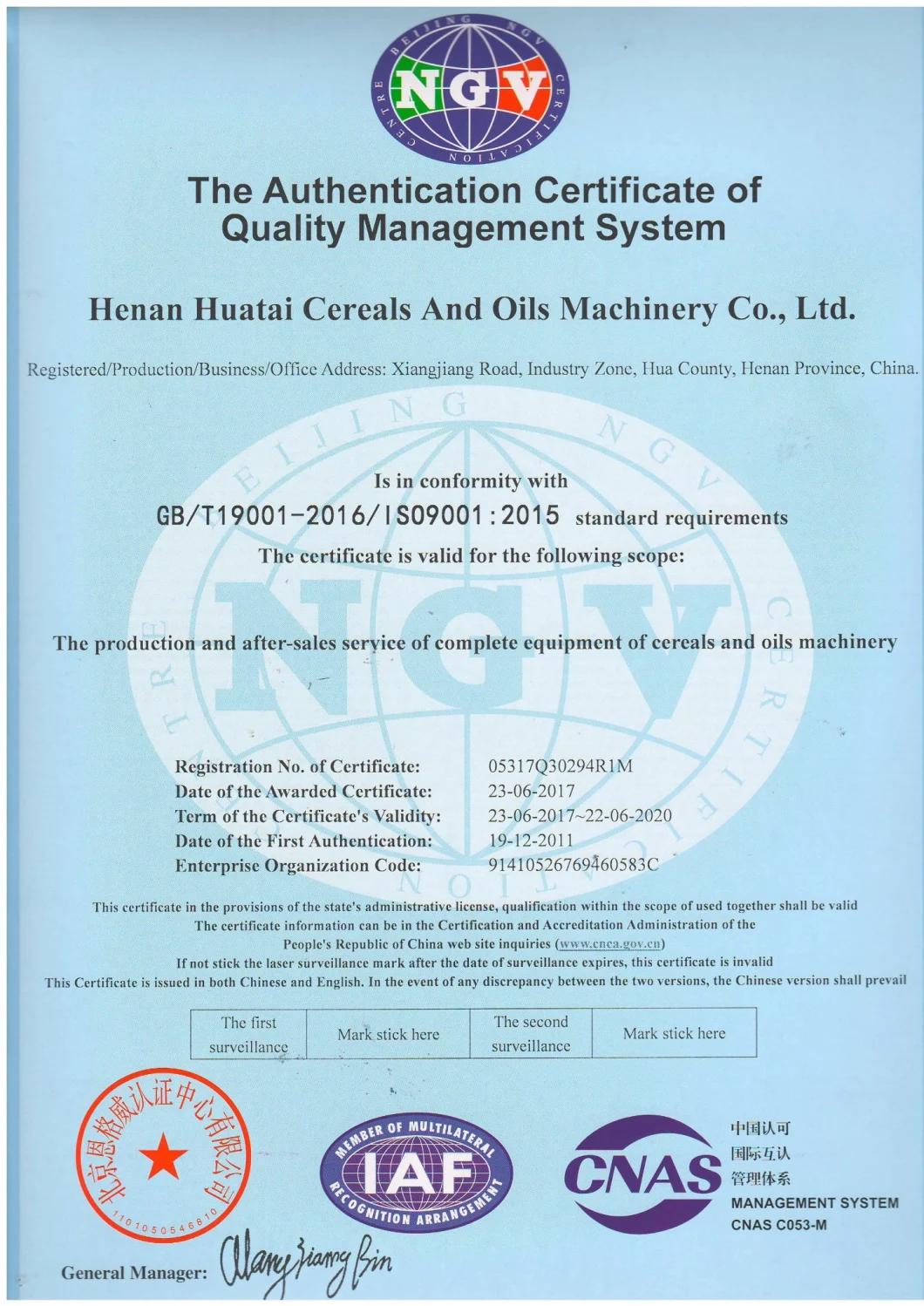

Our Company

Henan Huatai Cereals And Oils Machinery Co.,Ltd. was founded in 1950,whcih is a large-scale oil machinery manufacturing enterprise integrating R & D, design, manufacture and installation as one of the major grain and oil machinery manufacturing enterprises in China.Our company headquartered located in Huaxiang County Industries,Henan Province,China,covering 100,000.00 square meters.

Henan Huatai is committed to develop into a modern international oil machinery goal.Our company was named the outstanding member of the Chinese Cereals and Oils Association, the provincial contract and trustworthy enterprises, the provincial enterprise technology center.Huatai machinery has the rights of import and export, passed ISO9001: 2008 quality system certification.Now,the company is adhering to the scientific management of modern enterprises, precision manufacturing, innovation, and the rapid rise of a domestic grain and oil machinery manufacturing leader deserved.

Henan Huatai Cereals And Oils Machinery Co.,Ltd is committed to R&D of new efficient oil machines, manufacturing customer oriented oil machines, and leading the development direction of the world's most advanced grain processing machines and oil processing machines. We are reply on technology and innovation, constantly developing new type oil machines and equipment in order to achieve worlds advanced level.

Henan Huatai oil processing equipment sold in more than 30 provinces and cities in China and exported to the United States, Sweden, Japan, Korea, Bolivia, Sudan, Kazakhstan, Tajikistan, Russia, Malaysia, Indonesia, Bangladesh, Myanmar, Vietnam, Thailand, Rwanda, Nigeria, more than 130 countries and regions.Henan Huatai Cereals And Oils Machinery Co.,Ltd constants on the goal of Chinese leading food and oil machinery engineer, leading on advancement of oil industry. We are ready to meet all challenge and opportunities with full confidence and energy.Huatai machineryhas developed into a large-scale oil machinery manufacturing base in China.

Quality and Service Commitment

Our company always put the interests of customers and product quality to the first place, and always adhere to the"no best, only better" as our purpose. We will be commitment to provide high quality products with perfect site services and after-sale service.

Now the specific commitments are as follows:

1.Ensure to timely provide complete sets of equipment and accessories.

2.Ensure that one-time installation debugging acceptance.

3.To provide high quality material with preferential price.

4.Priority to provide customer our new craftworks and products.

5.Free training technological operator to ensure the trained staff can operation independently.

6.In the installation process,we will appoint a installation supervision staff on the spot.

7.we will offer an experienced project manager, organize a good installation team for the work of field installation debugging.

8.After the equipment field assembly and installation, we will be also responsible for the single equipment debugging, online debugging and Feeding trial operation,to ensure that equipments can normal operate in full load conditions. We will provide all kinds of information and records according to the requirements of the bid. The qualified completion files will be provided to customers according to their requirements

within one month after acceptance.

9.In the warranty period, all because of the quality of products has caused the damage or failure of equipment, suppliers will take the responsibility for the free repair and replacing spare part.

Due to the damage caused by the customer,we only charge material costs for repair and replacement.

After the receipt of customers notice,we will suggests the method to solve problem within six hours,or send specialist to the site to solve the problem within twenty four hours.

Contact us

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23