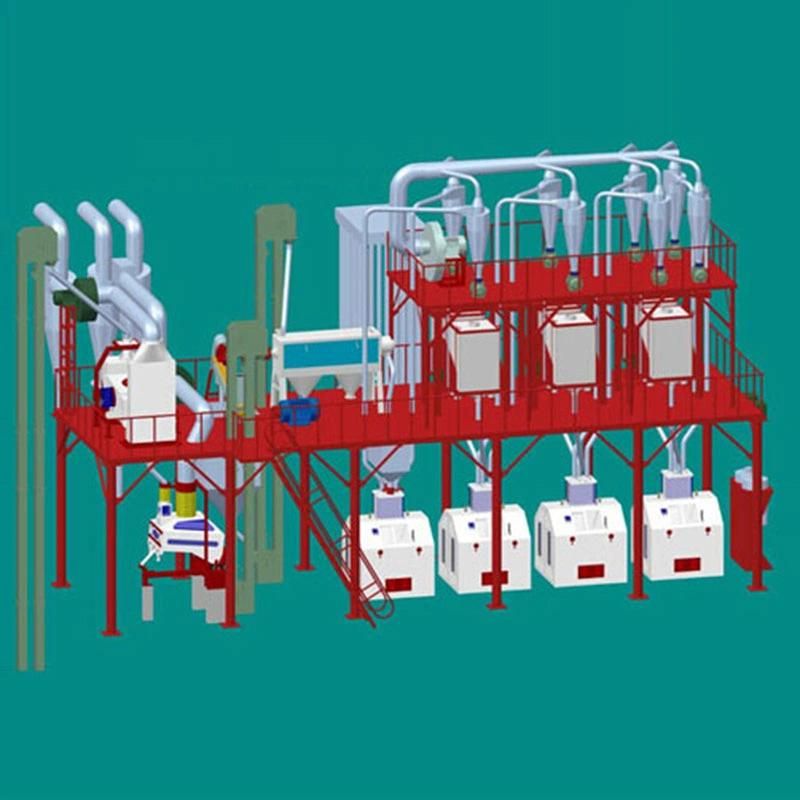

50t Per Day Corn Flour Processing Machine

Heshan Jile Industrial Co., Ltd. / 2022-07-05

- Application:Corn, Maize

- Customized:Customized

=== Base Info ===

- Model NO.:flour mill

- Certification:ISO9001

- Power Source:Electric

- Automatic Grade:Automatic

- Structure:Steel Frame Structure

- Capacity:50t,D

- Condition:New

- Voltage:380V,50Hz

- Transport Package:Mill Standard Package Suitable for Sea Transport

- Specification:30000*9000*7200 mm

- Trademark:MOLE

- Origin:China

- HS Code:84378000

- Production Capacity:20 Sets Per Month

=== Description ===

Basic Info.

Model NO. flour mill Certification ISO9001 Power Source Electric Automatic Grade Automatic Structure Steel Frame Structure Capacity 50t/D Condition New Voltage 380V/50Hz Transport Package Mill Standard Package Suitable for Sea Transport Specification 30000*9000*7200 mm Trademark MOLE Origin China HS Code 84378000 Production Capacity 20 Sets Per MonthProduct Description

50T/D Maize Milling MachineMain Equipment

1. storage (silos, or warehouse)

2. cleaning system (sifter, destoner, seprater, magnet, scourer, etc)

3. dampening (dampener, conditioning silos, etc)

4. milling system (roller mill, plansifter, purifier, impact detacher, etc.)

5. Flour pressure and blending system (if need)

6. flour packing and stacking

CLEANING SYSTEM

> Pre-cleaning section

1. Pour the pre-clean maize into the storage tank.

2. Clean out some big impurity to protect the discharge outlet not to block up when feed to flour mill and also protect the following equipment working safely.

3. Remove dust in the maize. To be more pure in the work shop, the flour milling machine can remove 90% big impurity and 95% dust.

> Cleaning Section

Further to clean out the middle and small impurity from maize, dust, stone, magnetic material, maize was bitten by insect and so on. After cleaning section, grains reach food standard.

In the cleaning process, maize will be added right moisture that suitable for next step - milling. After dampening, the final flour will be good.

MILLING SYSTEM

1. Adopt roller mill to mill. Automatically adjust roller distance according to stock quantity and stock variety.

2. We use suitable plansifter, bigger sieve area, which can improve products' quality.

3. With purifier, less bran residual, increase flour whiteness.

PACKAGE AND TRANSPORTATION

Our packing machine is fully automatic weighting and packing. The precision is more than 99.8%. Like 25kg/bag, the weight is not less than or no more than 50g.

Finished products

Maize flour, maize grits (meal),maize germ, bran and animal fodder.

Packing & Shipping

1.We will pack flour mill machine by the protect film inner,water-repellent plastic outside.

2.The wood packing is necessary if send by less than a container.

3.The flour mill machine will fixed by steel rope in the container.

Make sure it is in good condition when arrived destination.

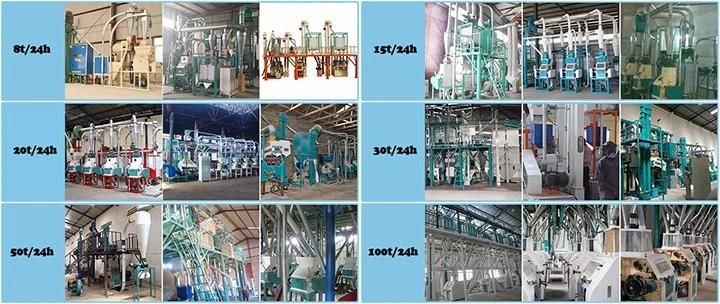

Related products

FAQ

1.Q: Which kind flour mill you can processed? And the output?

A: We can offer wheat flour mill and maize/corn flour mill with the capacity 5T/24H ----1000T/24H

2.Q: What is the basic processing step?

A: Full automatic line :

Cleaning the raw material------Milling the material into flour--------Packing the flour into bags.

3.Q: Which kind final products we can get from the maize / corn flour mill?

A: Maize flour, maize grits (meal),maize germ, bran and animal fodder .

Contact information

MOLE Machinery

Contact person: Emma

Website: molemachinery.en.made-in-china.com

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23