Ce Snack Food Chocolate Machine Energy Bar Bottom Coating Machine

SHANTOU DAFU PLASTIC PRODUCTS FACTORY CO., LTD. / 2022-07-04

- After-sales Service:Online Support

- Warranty:1 Year

- Certification:CE, ISO9001

- Power Source:Electric

- Process:Concentration and Dry

- Automatic Grade:Automatic

=== Base Info ===

- Model NO.:TYJ600

- Application:Ice Cream, Candy, Chocolate, Popcorn, Chips, Biscuit, Donut

- Customized:Customized

- Name:Chocolate Enrober

- Mesh Belt Width:550mm

- Conveyor Belt Width:600mm

- Cooling Tunnel Length:16000mm

- Cooling Tunnel Temperature:0-10ºC

- Material:SUS304

- Coating Type:Full Coating,Bottom Coating

- Weight:2300kg

- Total Power:24.44kw

- Transport Package:Standard Export Wooden Case

- Specification:600mm

- Trademark:Gusu Machinery

- Origin:China

- HS Code:8348200000

- Production Capacity:5000 Sets,Year

=== Description ===

Gusu New Designed Chocolate Enrober Advantages

Gusu New Designed Chocolate Enrober AdvantagesMachine appearance is similar to European equipment which is well-looking and more hommization.

Cover and closing board are designed simple and elegant which is easy for operate and maintain.

Chocolate Paste Hopper can be pushed and pulled very flexible. Easy to clean and leaving no dead angle.

The fan cover has a streamlining design to make the cooling more efficient and sufficient. The evaporator is specially designed(gained patent) to reduce the humidity of cooling tunnel effectively and make high quality chocolate.

This enrober can produce fully coated and half coated chocolate products. The thickness of coating area is controlled by fan speed and vibration.

The food grade PU conveyor belt has a automatic correction device and the whole line is controlled by PLC.

The length of the whole enrober line can be adjusted according to customer's requirements.

Combinatorial Arrangements

Automatic feed mechanism which can reduce operation staffs to improve production efficiency.

Patterns decorator which can make different colors of curve patterns coated on the surface to improve product level.

Material Spreader which can spread crushed peanut, sesame or other nuts granules on the chocolate surface to enhance flavors

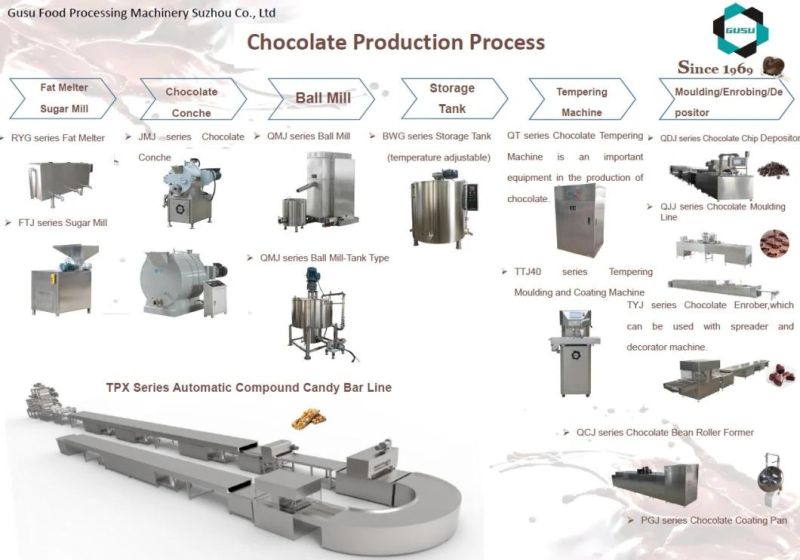

Chocolate Production Process

About Gusu

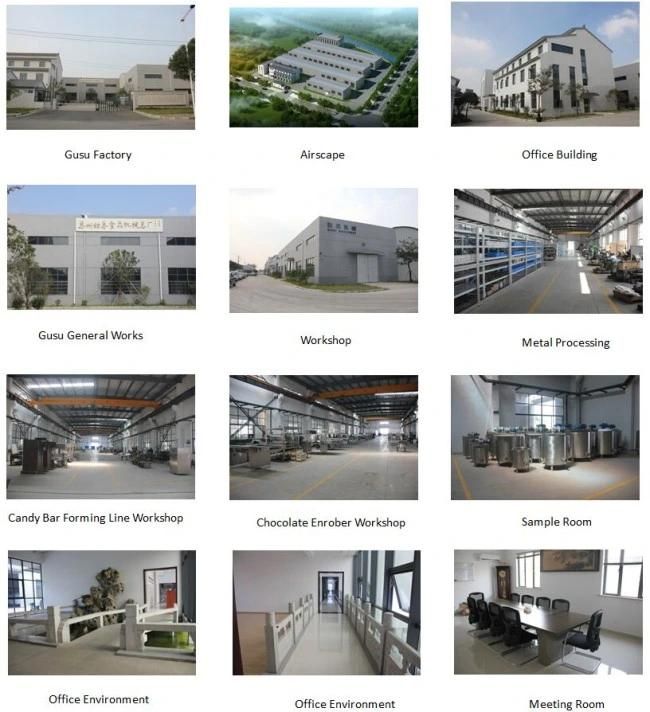

Over 40 years, Gusu insists on a corporate philosophy of people-oriented, be loyal to customers and credit management, we aim at the first class equipments and technologies worldwide in the industry, we connected with the food industry, scientific and technological enterprises and universities to make continuous improvements, innovations and development of the products in order to provide better service to customers. Products are sold all over China and more than 80 countries and regions.

Gusu Food Processing Machinery Suzhou Co.,Ltd., formerly known as Gusu General Works of Food Processing Machinery Suzhou, founded in 1969, is also the first enterprise making complete sets of chocolate machinery in China and honored as "the Mother of Chocolate in China".

Gusu expanded and moved to the new factory in 2014 which covers more than 30,000 Square Meters with beautiful environment and convenient transportation, "Suzhou Food Engineering Research Center" was founded in our new factory. Gusu has certified by ISO9001:2008 and CE, with a number of national patents.

Gusu expanded and moved to the new factory in 2014 which covers more than 30,000 Square Meters with beautiful environment and convenient transportation, "Suzhou Food Engineering Research Center" was founded in our new factory. Gusu has certified by ISO9001:2008 and CE, with a number of national patents.The purpose of Gusu is daring to scale the heights and striving for industry pioneer, we will continuously work on scientific research and innovations, provide customers with better and better service. We warmly welcome customers worldwide to Gusu to conduct and consult.

1 How to Order

1. Customer send us an inquiry.

2. Confirmmachine type, order quantity, price, lead time, payment term etc.

3.Our sales send the Proforma Invoice with company seal.

4. Customer make the payment for deposit and send us Bank receipt.

5. Inform the clients that we have got the payment,and will arrange the production according to yourrequest, inform the estimated time

6. Production products photos will send to you for approval.

7. Clients make payment for balance and Ship the goods .

8. Order is finished when you receive the goods and satisfy with them .

9. Feedback to us about Quality , Service, Market Feedback & Suggestion.And we can do better

2 About after-sell service

Usually machine guarantee time is about 1 year . Within guarantee time . Machine breaking caused bymachine itself design defect , we are responsible for it .we can provided free charge breaking part .If machine breaking caused by humane factor , user need take responsibility for it , we will providedtechnical support .

3 About goods shipping

We have long time working shipping forwarder. We can do our best to send machine to your port safe and quickly.

4 About our online Service

24 hours online to solve any problem .

Your email will be reply within 12 hours .

Your satisfy is our pursuit .sincerely hope our cooperation

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23