Fully Automatic Bubble Film Extruder

Hengshui Koster Hardware Products Co., Ltd / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. PE-1000 Engagement System Full Intermeshing Screw Channel Structure Deep Screw Automation Automatic Computerized Computerized Transport Package Film Specification 6000*1400*1850mm Trademark Ruifeng Origin China HS Code 847780000 Production Capacity 20psc/MonthProduct Description

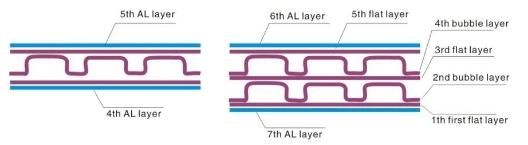

PE-1000 7 layer Bubble Film Extruding Machine

Features:

This aircrew adopts the disposable shaping craft. It is our factory that draws domestic and international advanced technology extensively, through a large number of production practices in having ordinary equipment originally, develop, designing, can produced polyethylene compound bubble(cushion) membrane in succession. Designs science, practical. Rational in structure of the machine.

Application:

The bubble film is made of LDPE material. It can be used for various packaging purposes such as moisture proving, dust proving, shock proving, and static prevention. It can also make into laminated films with aluminized film, foamed PE sheet, and paper are the applications of sun shading, heat insulation, and packaging.

Sample:

Main technical parameters:

Part 1: parts of the main extruder No.1

1,Reducer Model :Hardened reducer

2,Screw rod diameter:70mm

3,Long and diameter proportion:32:1

4,Screw rod material tube material quality:38CrMoALA nitrogenization treatment

(zhoushan city,zhejiang province,china)

5,Actuation form: 18.5kw Made in China

6,the way of Adjustable speed:KEWO Inverter/CE approved( frequency control)22kw

7,heating section: digital temperature control in Four districts

8,heating power: 10.8kw

9,tee heating :one area

10,heating power:2.5KW

11,Auto loader *1set

Part 2,Die head

1,shape: T-Die head

2,number of the extrusion sheets: two tiers

3,max. making width:1020mm

4,heating section: four area

5,heater: cast aluminum heater

5,heating power: 15.8KW

Part 3,parts of the main extruder No.2

1,Reducer Model :Hardened reducer

2,Screw rod diameter:70mm

3,Long and diameter proportion:32:1

4,Screw rod material tube material quality:38CrMoALA nitrogenization treatment

(zhoushan city,zhejiang province,china)

5,Actuation form:Made in China18.5kw

6,the way of Adjustable speed:KEWO Inverter/CE approved( frequency control)22kw

7,heating section: digital temperature control in Four districts

8,heating power: 10.8kw

9,tee heating :one area

10,heating power:2.5KW

11,Auto loader *1set

Part 4,Die head

1,shape:T-die head

2,number of the extrusion sheets: two tiers

3,max. making width:1020mm

4,heating section: four area

5,heater: cast aluminum heater

5,heating power: 15.8KW

Part 5,Formation mold

1,Max. making width:1020mm

2,way of the molding: vacuum pressure

3, way of the cooling water: cooling water

4,shape of the driving: Inverter (Ruian,Zhejiang)

5,the way of Adjustable speed: Inverter/Ruian,Zhejiang

6,Reducer: Cycloidal reducer

7,driving power :1.5kw 6Grade

8,bubble size: Φ10mm*4mm

Part 6:Pull

1,diameter of the flattened stick:200mm

2,material of the flattened stick: steel chromeplate

3,number of the flattened stick:5 twigs

4,number of the slip stick: 8 twigs, diameter of 80mm

5,shape of the driving: 1.5kw

6,the way of Adjustable speed:Inverter/Ruian,Zhejiang

7,Reducer:Cycloidal reducer

Part 7,Vice extruder

1,Reducer Model: Hardened reducer

2,Screw rod diameter:55mm

3,Long and diameter proportion:32:1

4,Screw rod material quality: 38CrMoALA nitrogenization treatment

(zhoushan city,zhejiang province,china)

5,Actuation form: Made in China

6,driving power:11kw

7,The way of adjustable speed: KEWO Inverter/CE approved( frequency control) 18.5kw

8,heating section: digital temperature control in four districts

9,heating power: 10.8kw

10,Tee heating power: 2kw

Part 8,Vice extruder's die head; thickness of chromium plating:50um

1,shape: T-Die head

2,number of the extrusion sheets: one tiers

3,max. making width:1020mm

4,heating section: four area

5,heater: cast aluminum heater

5,heating power: 15.8KW

Part 9.Automatic Rolling /Winding

1,Electrical machinery:Inverter motor

2,Auto winding and Auto changing: 1.5kw

(1),PLC frequency control

3,Winding tension:5Kg Magnetic Tension *2set

4,Cutting Cylinder:25mm*1150mm(Imported)

5,Cutting lifting Cylinder:85mm*500mm(2 Twigs)

6,Winding reel:72mm*1150mmz(2 Twigs)

7,Computer Control:DELTA PLC

8,Diameter of the rolling:φ1200mm (standard)

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23