Perfect Laser Fabrics Laser Engraving and Cutting Machine

Zhangpu Guangguang Plastic Products Co., Ltd. / 2022-06-23

- After-sales Service:Online Support

- Warranty:1 Year Warranty

- Application:Leather Industry, Domestic, Carpentry, Printing & Packaging, Advertising Industry

- Cooling System:Air Cooling

- Technical Class:Continuous Wave Laser

- Automatic Grade:Automatic

=== Base Info ===

- Model NO.:PEDK-160100S

- Applicable Material:Nonmetal

- Type:Flat-Plate

- Laser Classification:Free Electron Laser

- Engraving Method:Vector Engraving

- Laser Model:Sealed CO2 Laser Tube

- Processing Table:Work Platform

- Laser Power:150W Optional 100W 130W

- Machine Power:3kw

- Cutting Speed:0-72000mm,Min

- Interface Port:USB Ports

- Cutting Thickness:0.3-20mm

- Workhumidity:5-95% No Condensation

- Controlling Mode:CNC Professional Control System

- Cooling Mode:Water Cooling and Protect System

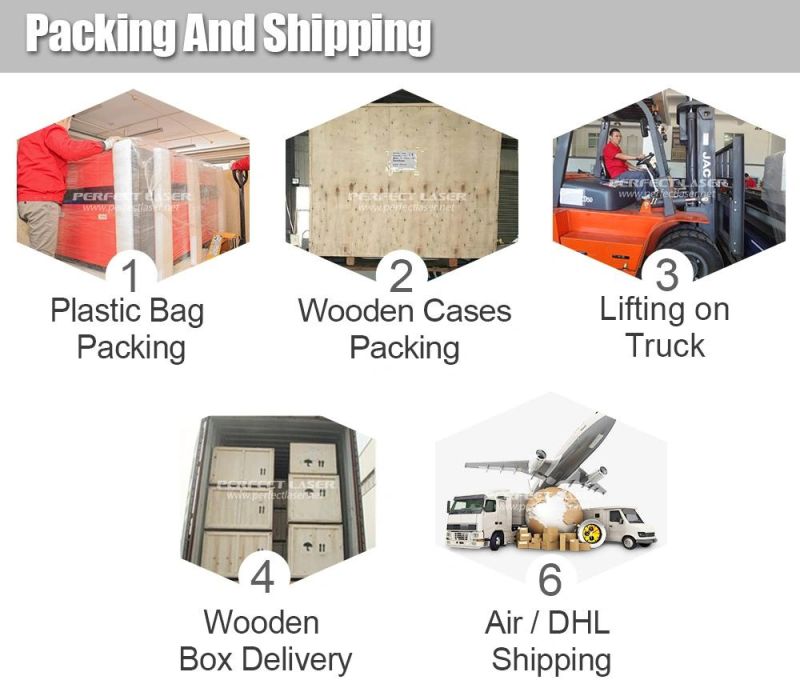

- Transport Package:Wood Package

- Specification:ISO 9001 & CE

- Trademark:Perfect Laser

- Origin:China

- Production Capacity:500sets,Month

=== Description ===

Basic Info.

Model NO. PEDK-160100S Applicable Material Nonmetal Type Flat-Plate Laser Classification Free Electron Laser Engraving Method Vector Engraving Laser Model Sealed CO2 Laser Tube Processing Table Work Platform Laser Power 150W Optional 100W 130W Machine Power 3kw Cutting Speed 0-72000mm/Min Interface Port USB Ports Cutting Thickness 0.3-20mm Workhumidity 5-95% No Condensation Controlling Mode CNC Professional Control System Cooling Mode Water Cooling and Protect System Transport Package Wood Package Specification ISO 9001 & CE Trademark Perfect Laser Origin China Production Capacity 500sets/MonthProduct Description

Perfect Laser Fabrics Laser Engraving and Cutting Machine(Model: PEDK-160100S)

Contact: Lisa

Introduction:

Perfect Laser is a world leading manufacturer for carpet cutters.

This carpet cutters is specially designed for carpet cutting and related auto-car interior decoration materials. The carpet cutters can do cutting process for various kinds of car interior decoration materials like leather, fabric, cotton, plastic, rubber items, etc.

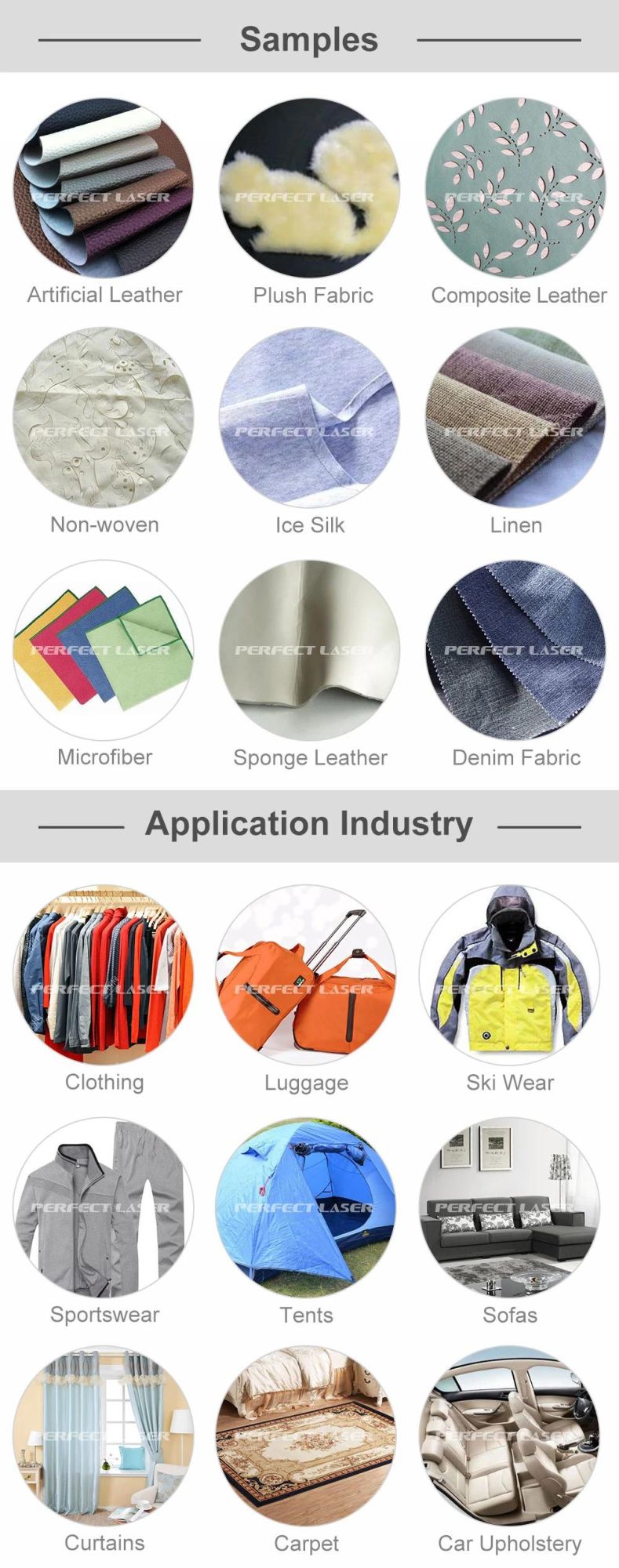

Application & Samples:

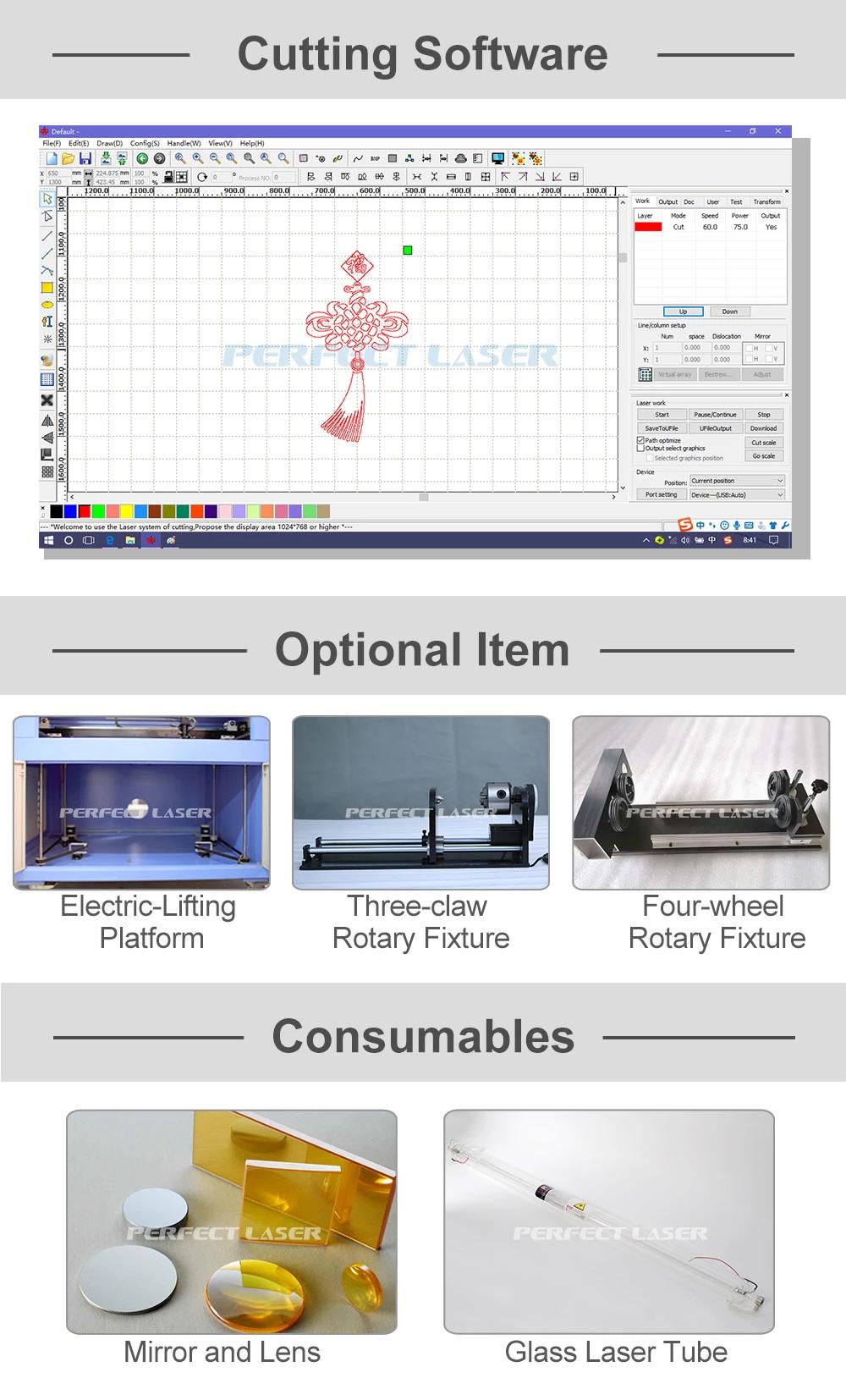

Laser Engraving Machine has been widely used in the fields of plexiglass, architectural models, rubber plates, bamboo products, the cutting and carving and plexiglass products, acrylic art&crafts panel lenses, wood carving, wood, advertising materials, crystal characters, easel, packing boxes, models, toys and furnitures.

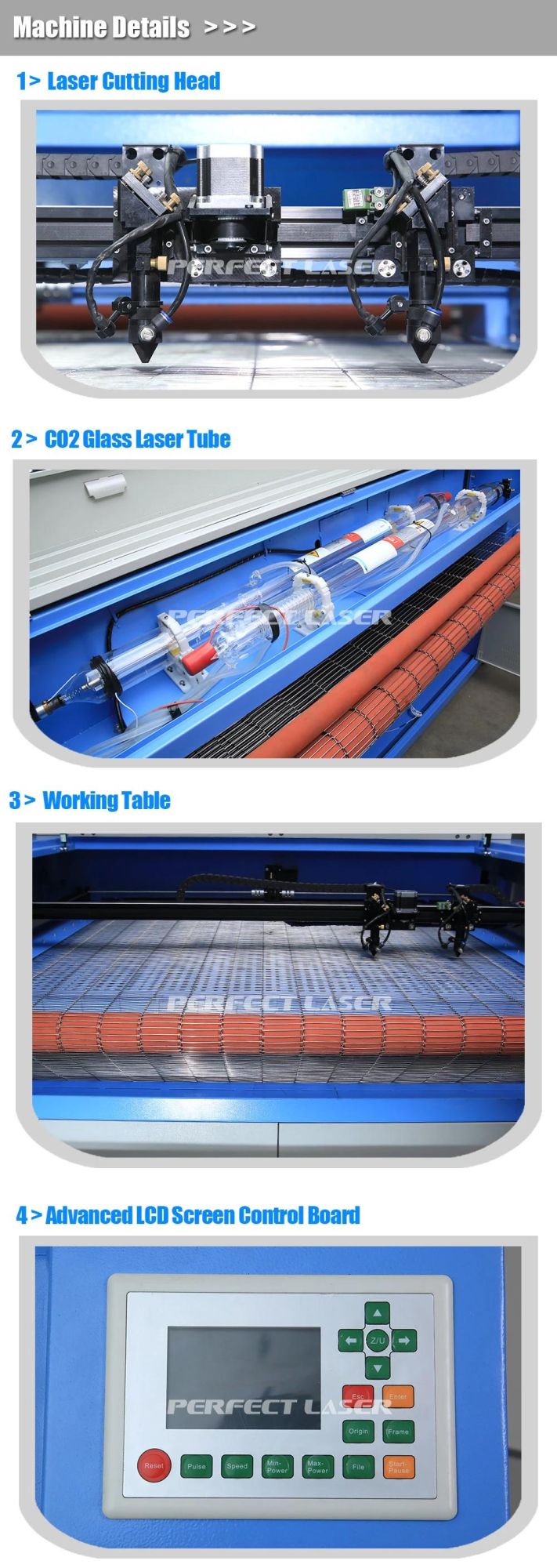

Machine Structure:

Product Features:

Product Features:1. Equip with working table and auto feeding system, which can do continuous feeding and precision cutting.

2. Continuous stitching function. The uncompleted cutting graphic on one material will be automatically deferred to the next material. It can cut inner parts and frame parts for one graphic at the same time by just feeding once. Intelligent typesetting system get the most effective and rational use of materials.

3. Continuous cutting function when power off. Cutting device can automatically memory cutting status when power off, machine can continue cutting after power on.

4. Equip with mini air compressor and air pump

5. Equip with Imported focus lens and mirrors, fine laser beam, strong laser power, avoiding laser power attenuation when cutting caused by optical transmission problems using traditional laser equipment.

6. Adopt strong cooling industrial-grade equipment to ensure a long operating cycle when the water temperature is always kept cold state, the laser tube light stability, and to ensure that the laser tube life;

7. Adopt Taiwan Hiwin precision linear square rails, to ensure the smooth operation of the laser head, high-speed, no jitter, having slit small, fast, high accuracy;

8. Easy operate, more humane design, users are more likely to start with;

9. Increase the added value of products. Laser cutting is not required pattern cloth version, you can freely copy crop patterns, especially for revision requirements. In the process, a laser cutting, drilling and carving and other innovative technology integration which greatly improve the value-added products.

10. Improve production efficiency. You can roll the entire fabric automatic cutting, automatic cutting, on the basis of the production process at one go. One end of a single laser cutting machine out of the material to meet the five skilled workers sewing production.

11. Save the provincial labor, and material. Because the laser is intelligent analog layout, simple, requiring workers to operate only need to know the computer. When cutting leather for leather car seat covers also avoids bad dermis, thus improving the cutting quality, reducing leather waste.

Company information:

Perfect Laser was founded in 1995, located in Wuhan city. We have 24 years experience in this field. our products get favorable sales success and outstanding reputation not domestically in China but also popular in more than 180 countries, Our company has the CE certificate, ISO9001:2000 ISO quality system certificate.

Here is the website: perfectlaserco.en.made-in-china.com.

We produce 12 series product ranges and 200 different models, attached please kindly find the machine styles and the related price. Also, welcome to visit our website perfectlaserco.en.made-in-china.com to get an overall idea about our products and quality.

Contact us:

Perfect Laser Co.,Ltd. (China)

Contact: Lisa / Sales Manager

Add: No.13 YangQiaohu Road, East Lake High-tech Development Zone, Optics Valley, Hubei, China

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23