Men′ S Shirt Collar Laminating Machine

Jing Yi Fine Aquarium Limited / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

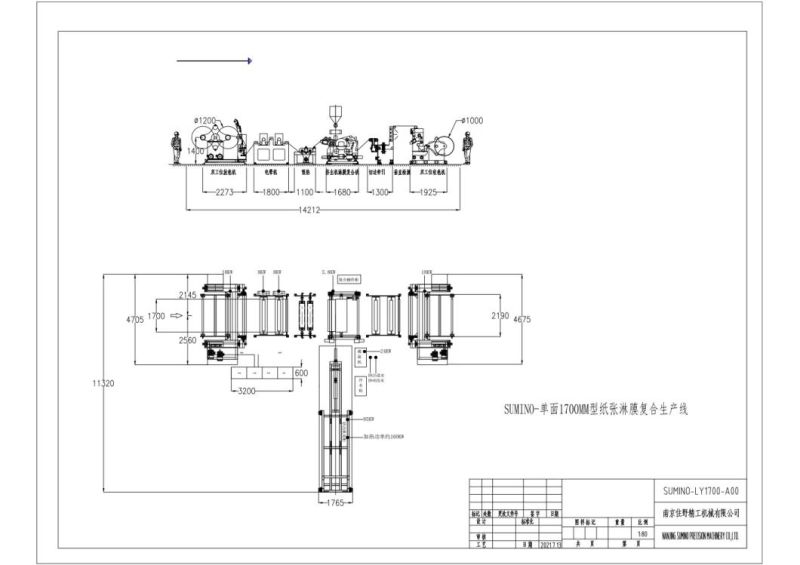

Model NO. ZY-1000 Assembly Structure Integral Type Extruder Screw Single-Screw Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Don′t Exhaust Automation Automatic Computerized Computerized Mechanical Specifications 1100-2300mm Speed of Coating Film 100-150 Thickness of Coating Film 0.012~0.1mm Effective Screw L/D 30:1 Main Unwinding Diameter 800-1300mm Speed of Screw 50-150 Rpm Gross Weight Around 10 Tons Total Power 150 Kw Transport Package Wooden Cases Specification 13000*8300*3200mm Trademark SUMINO Origin Nanjing China HS Code 8477402000 Production Capacity 30Product Description

Composition of film coating machineThe whole machine is composed of feeding device, extruder host, die, unwinding device, compound device, winding device, edge position control device, edge cutting device, heating and cooling system, electrical measurement and control system, etc. According to the needs of different products, the second unwinding device, printing equipment, oven, substrate surface treatment device (Corona machine, etc.), on-line thickness gauge and other components can be added. Previous process: granulator, printing press or other equipment; Equipment for subsequent process: Slitter or other equipment.

Classification by extrusion speed

1. Low speed extrusion casting compound machine

2. Medium speed extrusion casting compound machine

3. High speed extrusion casting compound machine

Classification by base material layers

1. Single substrate film coating machine

2. Multi substrate film laminating machine

3. Multi in one substrate film coating machine

Classification by substrate type

1. Paper coating machine

2. Plastic film coating machine

3. Non woven and non-woven film coating machine

4. Woven cloth film coating machine

5. Grid cloth film coating machine

6. Other base material coating machine

Application of film coating machine

1. Food industry

2. Packaging industry

3. Beverage industry

4. Pharmaceutical industry

5. Printing office industry

Product Application

Non woven fabric is made of chemical fiber and plant fiber on wet or dry paper machine with water or air as suspension medium. Although it is cloth but not woven, it is called non-woven fabric. Non woven fabric is a new generation of environmental protection materials, which has the advantages of good strength, air permeability and waterproof, environmental protection, flexibility, non-toxic and tasteless, and low price. It is a new generation of environmental protection materials, with the characteristics of water repellent, breathable, flexible, non combustion supporting, non-toxic, non irritating, rich color and so on.

(1) Medical and sanitary non-woven fabrics: surgical clothes, protective clothing, disinfection bags, masks, diapers, civilian rags, wiping cloth, wet face towel, magic towel, soft towel roll, beauty products, sanitary napkins, sanitary pads, disposable sanitary cloth, etc.

(2) Non woven fabrics for home decoration: wall cloth, tablecloth, bedspread, bedspread, etc.

(3) Non woven fabrics for clothing: lining, adhesive lining, flocs, shaped cotton, various synthetic leather substrates, etc.

(4) Industrial non-woven fabrics; Base material, reinforcing material, polishing material, filter material, insulating material, cement packing bag, geotextile, wrapping cloth, etc. of roof waterproof coiled material and asphalt tile.

(5) Non woven fabrics for agriculture: crop protection cloth, seedling raising cloth, irrigation cloth, thermal insulation curtain, etc.

(6) Other non-woven fabrics: Space cotton, thermal insulation and sound insulation materials, linoleum, smoke filter, tea bag, shoe materials, etc.

Environmental protection bag, gift bag, shopping bag, advertising bag, suit bag, advertising apron, non-woven hand-held bag, non-woven hanging bag, non-woven bag, gift bag, cosmetic bag, mesh bundle mouth, non-woven computer cover, TV cover, air conditioning cover, washing machine cover, dust cover, pillow cover, shoe cover, high-grade non-woven mattress, hotel non-woven disposable products. Non woven sauna products include: Sauna clothes, bathrobes, bath pants, paper underwear and other environmentally friendly non-woven products.

Product Features

Futures of Full Automatic roll laminating film textile machine automatic thermal laminating machine

This series of products are mainly plastic film,EVA,Foam,aluminum foil as substrate, by casting a compound into two layer, three layer (sandwich), widely used in foam packing material . Such as making baby game pad, car window sunshade and so on. PLC man-machine interface control, machine, electricity, gas, integrated design; high precision Die head, high efficiency, high speed mixed refine screw, swift filter screen changer, 360o second reel;

This series of Extrusion Lamination Machine can be equipped with a single extruder. Double screw extruder, multi-stage attack realize multi-layer co-extrusion.

Customer Factory Inspection

About Us

Nanjing Sumino Precision Machine Co., Ltd. is a high-tech company integrating scientific research, production and sales. The company is located in the beautiful eastern city of Nanjing, adjacent to the airport, high-speed railway station and bus station, with convenient transportation. At present, the factory has more than 8000 square meters, more than 100 employees, including 20 senior engineers. Company R&D and production of plastic machine and packaging machine. At present, the products have been delivered to more than 20 provinces and cities in China, and exported to Europe, Iran, Turkey, Vietnam, Korea, Japan, Malaysia, India, Thailand, Mexico, Canada and other countries and regions. It has established long-term cooperative partnership with many research institutions. The company has always adhered to the business philosophy of integrity, equality, customer interests first, the products implement GB/T 19001-2000 IDT ISO 9001:2000 quality management system, and provide customers with support and personnel training.

In order to better improve the quality of equipment and enter a more professional and standardized production track, we have established six categories of equipment R & D technology center, they are plastic sheet materials, cast films, biaxial stretching systems, and non-woven meltblown fabrics, extrusion laminating composite materials, biodegradable plastic granulation production lines. After more than ten years of practice accumulation, we can provide the most professional full set of technical solutions to meet the special needs of each customer.

After sale service

FAQQ1: What is the guarantee of the machine?

A1: The guarantee period of our machine is 12 months after the machine is installed well in buyer's factory;

Q2: What package do you use for the machine?

A2: Painted the machine with anti-corrosion oil, and then covered with plastic film, and then packed into wooden case or fixed onto wooden pallet as per clients' requirements, or shall be loaded into container with film packing. After fixed all machines, we will use drying agent to keep container inside dry.

Q3: Do you have instruction manual to guide us if i buy the machine?

A3: Yes, we supply detailed user manual for your reference. PLS read it carefully for guide. If there is still problem which could not be solved, PLS contact us, we are ready to help you anytime.

Q4: What is your service to overseas clients?

A4: We supply perfect overseas service. We shall send engineers to overseas for machine installation and commissioning and test production guide, and also training to the workers of the buyer. And we are ready to give technical support anytime.

Contact:MikiInternational Business Development Department ManagerNanjing Sumino Precision Machinery Co.,LtdAdd: Kaituo Road No.11, Jiangning Distract, Nanjing, China.

Web: www.made-in-china.com/showroom/sumino / www.made-in-china.com/showroom/sumino

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23