350m/Min High Speed 0.15mm Thin Wall Flat Drip Irrigation Pipe Production Line

Zhejiang Longyou Huiyang Foreign Trade Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. SJ-60/38 Plasticizing Way Screw Type Clamping Way Mechanical Automation Automatic Computerized Computerized Certification CE, ISO9001:2008 Speed 320m/Min Transport Package Wooden Specification 20-25m*5m*3.5m Trademark XINDACHENG Origin Qingdao ChinaProduct Description

Drip irrigation pipe machine is a high-speed production equipment of thin-wall drip irrigation pipe independently developed by XINDACHENG. "ZEANON" is an independent brand developed by Qingdao Xindacheng together with European well-known drip line. Zeanon products cover all aspects of the drip irrigation field, including water-saving irrigation technology & machinery, engineering design, drip products and drip irrigation pipe machine.1. Dripper feeder device: double sets. Dripper feeding speed: 3000pcs/min.2. Have dripper buffer device, make sure non-stop machinery even if happen bad quality dripper block on feeder. 3. Extruder: Servo direct drive, save power.4. Extruder die head & calibrating: Germany technology, thickness adjustable.5. Configuration: One-button automatic pipe-holding dripper insert device.6. Irrigation pipe accumulator: equipped with the most advanced European parallel accumulator device.7. Automatic drilling device: 3 units. speed: 3000times/min.8. Configure online automatic imaging analysis and monitoring punching system: monitor the punching status, realize the error automatic alarm function, and ensure the product punching rate.9. Line speed 300m/min, it is the fastest production efficiency in the world.Flat drip irrigation pipes; Has been introduced to serve our farmers for the protection of our water resources, to save from energy, pesticides and fertilizers and to obtain the highest productiveness from the plants and trees. Flat drop irrigation pipes can be used for all plants that can be planted in line, sugar beet, corn, potatoes, carrots, sunflowers, and all types of field plants and decorative plants.

It performs safely under high pressure because it has been built jointless and it is a durable type of pipe that can clean itself.

It works without any problems with its long dripper labyrinth.

It can be rolled safely and put together many times because of its durable dripper.

It has been produced with variable flow rate, dripper range and flesh thicknesses providing the system to be installed easily under various conditions.

Is has a longer extension distance comparing to others.

It has the most advanced technology in the present irrigation systems. The principal in the drop irrigation is to provide the daily water need of the plant in the type of drops by not causing a high demand for water for the plant. In other words it means the irrigation of the plant not the soil. The chemical fertilizer application can be performed to meet the nourishment requirement of the plant every day or every 2-3 days with the drop irrigation method. Thus, it is possible to gain an important amount of yield and quality.

Advantages:

Can be stored easily, does not require too much space.

The gain in yield can reach up to the rates of 50-100 % depending on the climate of the region.

Provides a shorter development period for the plant and provide early harvest.

Provides irrigation with low pressure and low flow rate water.

Provides irrigation of larger fields with less amount of water comparing to other irrigation systems.

The drips placed in the pipe with specific distances provide the plant with required amount of water with required pressure.

Water does not leak deep and flow from the surface therefore there won't be loss of water...

It is the highest performing irrigation system in all irrigation systems.

Provides equal irrigation all around the field. It can be pulled to the long distances with its large scaled and special drippers. This specialty provides low main pipe cost.

Provides irrigation on the slopes without causing any erosion.

Provides irrigation in windy situations.

High performance and irrigation.

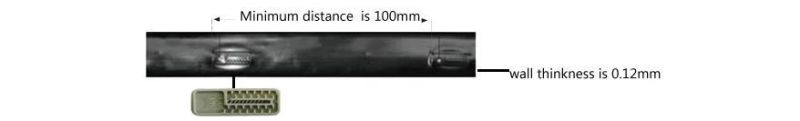

| Item | Pipe diameter | Pipe thickness | Production speed | Distance of dripper |

| Flat dripper irrigation pipe production line | Φ12-16-20mm | 0.15-1.0mm | 200m/min | 100150200300400500-1500mm |

Product description:

"ZEANON" is an independent brand developed by Qingdao Xindacheng together with European well-known drip line. Zeanon products cover all aspects of the drip irrigation field, including water-saving irrigation technology & machinery, engineering design, drip products and drip irrigation pipe extrusion line.

1. Dripper feeder device: one sets. dripper feeding speed: 1800pcs/min.

2. Have dripper buffer device, make sure non-stop machinery even if happen bad quality dripper block on feeder.

3. Extruder: AC or DC drive.

4. Extruder die head & calibrating: Germany technology, thickness adjustable.

5. Configuration: One-button automatic pipe-holding dripper insert device.

6. Irrigation pipe accumulator: equipped with the most advanced European parallel accumulator device.

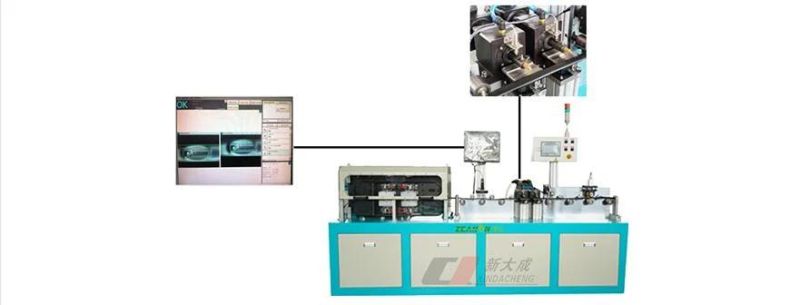

7. Automatica drilling device: 2 units. speed: 2000times/min.

8. Configure online automatic imaging analysis and monitoring punching system: monitor the punching status, realize the error automatic alarm function, and ensure the product punching rate.

9. Line speed: 300m/min, it is the fastest production efficiency in the world.

* dripper space 100mm, speed: 150m/min.

* dripper space 200mm, speed: 300m/min.

* dripper space 300mm, speed: 300m/min.

Feature 1: Zeanon irrigation pipe weights less than 7g/m, Reduce 30% material which will largely save cost.

Feature 2:

• Configured with advanced dripper dripper buffer and insertion unite (Europe technology).

• Insert 1500-1800 pieces of dripper per minute.

Feature 3:

• Europe import dripper, weights only 0.1g/pcs(China exclusive agent)

• Qingdao Xindacheng import from Europe, China exclusive agent.

• High efficient inner irrigation pipe dripper adopted high efficient injection mold technology.

• All produced in Europe, to make sure of the quality.

Feature 4:

• Double Auto Punching Unit, Punching device fixed with online monitor & picture indentify system, store the punching system.

• Auto alarm for wrong punching, it is controlled by PLC system.

• Tracking and adjust the punching system in time.

Feature 5:

• Auto winder + Accumulator device

• It is drive by servo motor. Automatically wind the dripper irrigation pipe.

• Controlled by PLC system.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23