110-315mm PE HDPE Pipe Production Line with High Efficient 90/33 Single Screw Extruder

Maanshan Songlin Doctor Blade & Saw Manufacture Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Overview

Product Description

PE water pipe extrusion line specially designed for PE water/drainage/sewage pipe,this production line to PE,HDPE material.

These final product pipe are mainly used in the area of agricultural water supply system, architectural water supply system, gas pipe, sewages pipes,pavement of cables,etc.

The main parts of the line are PLC control, high degree of automation .

Adopting compound spiral engine head , effectively deleting memory function of the material .

Adopting co-extrusion head to improve the tube color line.

Vacuum calibration , constant temperature control , eliminating pipe stress.

High extrusion capacity, low temperature of melt , equal temperature of melt.

Wide processing range of raw materials.

For different diameter range pipe,will be equipped with corresponding different production lines.

we can supply PE pipe production lines for diameter:

16mm,20mm,25mm,32mm,40mm,50mm,63mm,75mm,90mm,110mm,

125mm,160mm,200mm,250mm,280mm,315mm,

355mm,400mm,450mm,500mm,560mm,630mm,

710mm,800mm,900mm,1000mm,1100mm,1200mm.

PE pipe production lines generally for diameter from 16mm to 1200mm.

each different pipe production line will include:

vacuum loader+hopper dryer+single screw extruder+mould+vacuum forming tank+spray cooling tank+haul off machine+cutting machine+stacker.

16-110mm can be produced in same one line,

125-250mm can be produced in same one line,

or 110-315mm can be produced in same one line,

355-630mm can be produced in same one line,

400-800mm can be produced in same one line,

710-1200mm can be produced in same one line.

Detailed Photos

Here photos showed 110-315mm PE pipe making machine,for your reference.

Packaging & Shipping

Company Profile

- BEIERMAN MACHINERY was established by three skilled technician/engineer/sales for plastic extruding line, plastic recycling lines producing, sale and services.

- We have 3000 square meters working house for machines making, there are 40 workers for machines producing and a 5 engineers service team for the machines running test, installation, workers training and machines repairmen.

- we have already get CE certificate for our machines and factory, which ensured the high quality level of all machines we are producing

- we will attend several home and abroad plastic machines industry fairs to show the customers our quality, machines and services.

- there will be 1-2 new produced machines will be showed to the customers every year.

- we already established cooperation with the customers from Middle East, Southeast Asia and south America countries.After Sales Service

Pre-sales services

we will take customers to visit our factory and check the machines quality from airport/bus station/train stations

- we will re-designed the machines according to customer's different raw material formulations: driving motors power, electric power model, wall thickness of barrel, control method

After-sales services

we will offer electric diagram, installation diagram, usage manual

- we will offer the customers online introduction to solve the machines problems/send engineers for customers machines installation, running test, workers training, machines repairmen services.

- we will offer customers spare parts at cost prices all life long of the machines.

Exhibition

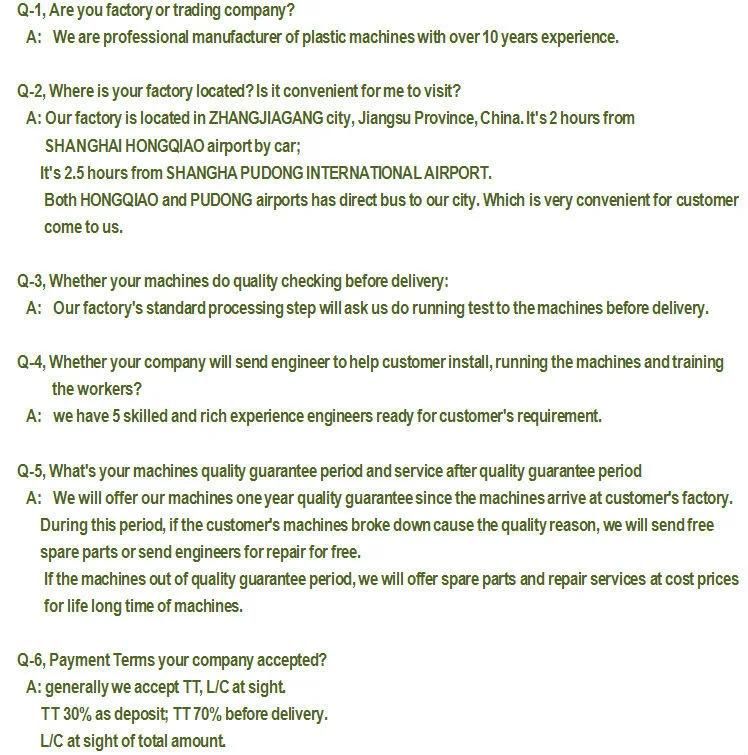

FAQ

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23