Small Bottled Water Production Line, Mineral Water Filling

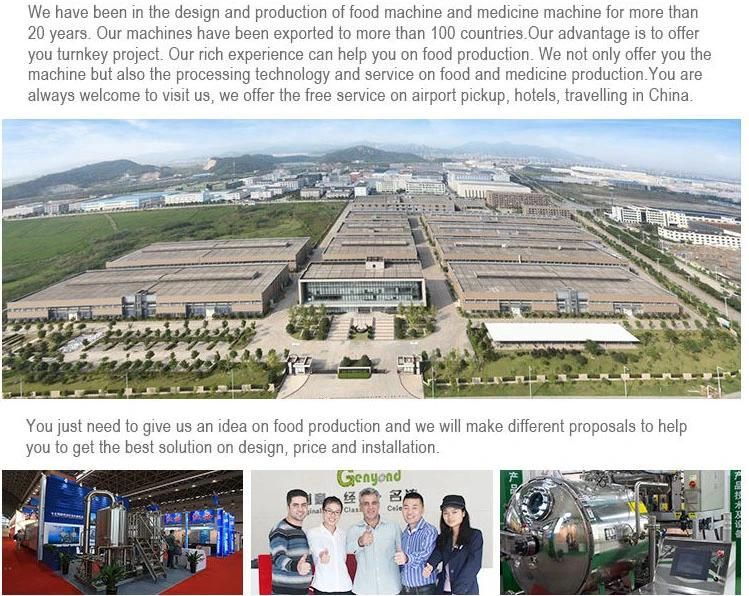

Jiangyin Yiran International Trading Co., Ltd. / 2022-07-05

- Condition:New

- Customized:Customized

- Voltage:220V

- Composition:Filling Machine

- Processing Material:Natural Ingredients

- Process:Frozen and Chilled

=== Base Info ===

- Model NO.:GYV-1000

- Material:Stainless Steel

- Function:Multifuction Mineral Water Machine

- Product Name:Mineral Water Machine

- Color:Silver

- Name:Mineral Water Machine

- Transport Package:Mineral Water Machine Wooden Boxes

- Specification:3*2*12

- Trademark:genyond

- Origin:Shanghai

- HS Code:8422301090

- Production Capacity:5000

=== Description ===

Basic Info.

Model NO. GYV-1000 Material Stainless Steel Function Multifuction Mineral Water Machine Product Name Mineral Water Machine Color Silver Name Mineral Water Machine Transport Package Mineral Water Machine Wooden Boxes Specification 3*2*12 Trademark genyond Origin Shanghai HS Code 8422301090 Production Capacity 5000Product Description

Main Feature

- This machine has a compact structure, perfect control system, easy to operate and highly automated.

- The parts contact with product is made of quality SUS, anti-corrosive, and easy to clean.

- By adopting high speed filling valve, the liquid level is precise and no waste. That guarantees the demand of filling technology.

- The capping head adopts constant torque magnetic device to guarantee capping quality and impact cap.

- This machine has a high efficient cap arranging system, perfect cap feeding and protection device.

- Equipped with perfect clean management system to ensure the bottle clean.

- Only by changing the star-wheel, can realize to fill the changed bottle shape.

- The machine adopts perfect overload protective device can ensure the operator and machine safe.

- This machine adopts adjustable frequency converter.

- The main electric components, frequency, photoelectric switch, proximity switch, electric control valves all adopt imported components, which can ensure the quality performance.

- The control system has many functions, such as control producing speed, cap shortage detection, bottle block automatic stop and production counting etc.

- The electric components and pneumatic components are all introduced from world famous brand products.

Factory Direct supply wrap around packer with good quality

The bottles are transported by conveyor, and be inspected and arranged according to the programmed process, after finishing complete carton arrangement, the cardboard supplying mechanism will send the send the cardboard into the machine, and the bottle dropping mechanism will drop the bottles into the cardboard, and than the cardboard folding mechanism will fold the cardboard, glue it and seal it step by step. The formed the carton will be send out of the machine by the roller, which improves the production efficiency and realize full automatic manless production.

Case packaging machine, wrap hinaround carton packaging machine, wrap around carton packing

Main configuration

l PLC Siemens

l Frequency converter Danfoss

l Photoelectric sensor SICK

l Servo motor Panasonic

l Pneumatic components SMC

l Low-voltage apparatus Schneider

l Touch screen Schneider/Siemens

Main equipment description

1. Conveyor system: the product will be divided and inspected on this conveyor.

2. Automatic cardboard supplying system: This equipment is installed in the side of the main machine, which stores the carton cardboards, the vacuumed sucking disk will indraft the cardboard into the guide slot, and then the belt will transport the cardboard into the main machine.

3. Automatic bottle dropping system: This system separates the bottles in carton unit automatically, and then drops the bottles automatically.

4. Cardboard folding mechanism: the servo driver of this mechanism will drive the chain to fold the cardboard step by step.

5. Lateral carton pressing mechanism: the lateral cardboard of carton be pressed by this mechanism to form the shape.

6. Top carton pressing mechanism: The cylinder presses the up cardboard of the carton after glueing. It is adjustable, so that it can suitable for different size of carton

7. Automatic system control cabinet:

Case wraparound machine adopt Siemens PLC to control the complete system of the machine.

The interface is Schneider touch screen with good display of production management and status.

Shanghai Gengyond machinery Technology Co.,Ltd. ADD: 709,No.1328,Hengnan, Road, Minhang District, Tony Wong

Shanghai Gengyond machinery Technology Co.,Ltd. ADD: 709,No.1328,Hengnan, Road, Minhang District, Tony Wong

Mob : 0086 18116095133

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23