Automatic Cutting Machine Leveler Decoiler Machine Zcl-8X1800

Shenyang Winbo Rommer Electronic Technology Co., Ltd. / 2022-06-23

- After-sales Service:Lifelong

- Warranty:12 Mouths

- Cooling System:Natural Cooling

- Technical Class:Production Line Cutter

- Applicable Material:Metal

- Structure Type:Desktop

=== Base Info ===

- Model NO.:ZCL-8x1800

- Laser Classification:as The Clients′s Requirements

- Laser Technology:as The Clients′s Requirements

- Material Width:1800 mm

- Material Thickness:3.0mm-8.0 mm

- Finished Length:5000 mm

- Length Accuracy:1mm

- Diagonal Accuracy:1 mm

- Line Speed:0-50 M, Min

- Coil Weight:10 to 30 Tons

- Leveling Accuracy:1 mm , M2

- Power:AC 380V 50Hz

- Option:Moving Shear

- Colour:Customized

- Transport Package:Seaworthy

- Specification:30 m L X 11 m W

- Trademark:ZeYe

- Origin:China

- HS Code:84623120

- Production Capacity:70

=== Description ===

Basic Info.

Model NO. ZCL-8x1800 Laser Classification as The Clients′s Requirements Laser Technology as The Clients′s Requirements Material Width 1800 mm Material Thickness 3.0mm-8.0 mm Finished Length 5000 mm Length Accuracy 1mm Diagonal Accuracy 1 mm Line Speed 0-50 M/ Min Coil Weight 10 to 30 Tons Leveling Accuracy 1 mm / M2 Power AC 380V 50Hz Option Moving Shear Colour Customized Transport Package Seaworthy Specification 30 m L X 11 m W Trademark ZeYe Origin China HS Code 84623120 Production Capacity 70Product Description

Cut to Length Line ZCL seriesCut to length line is mainly used for jobs like uncoiling, leveling, measuring the length, cutting and stacking of kinds of materials, such as cold rolled or hot rolled plate, electrolytic galvanized plate, hot dip galvanized plate, color-coated plate, stainless steel plate, aluminum plate, cooper plate etc.

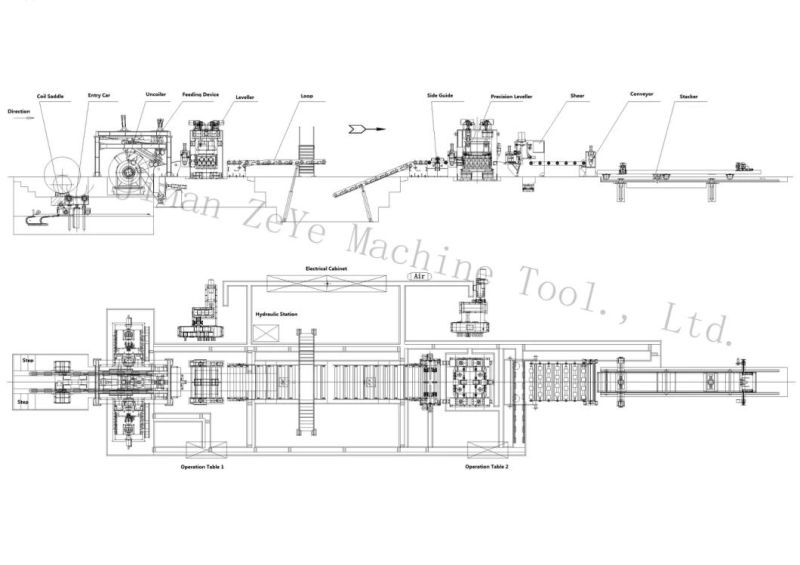

Main Units

| 1 | Entry coil car | 1 set |

| 2 | Uncoiler | 1 set |

| 3 | Feeding device | 1 set |

| 4 | Pre- leveler | 2 set |

| 5 | Looper | 1 set |

| 6 | Side guide | 2 sets |

| 7 | Precision Leveler | 1 set |

| 8 | Shear Machine | 1 set |

| 9 | Conveyor | 1 set |

| 10 | Stacker | 1 set |

Main Technical Parameters

| Model | ZCL-6 | ZCL-8 | ZCL-12 | ZCL-16 | ZCL-20/25 |

| Material thickness | 1.5-6.0mm | 2-8 mm | 3-12 mm | 4-16 mm | 6-20/25 mm |

| Material width | 800-2000 mm | 800-2000 mm | 800-2000 mm | 800-2200 mm | 800-2500 mm |

| Finished length | 1000-6000 mm | 1000-8000 mm | 100-12000 mm | 2000-14000 mm | 2000-14000 mm |

| Length accuracy | ±1.0 mm | ±1.0 mm | ±1.0 mm | ±1.0 mm | ±1.0 mm |

| Diagonal accuracy | ±1.0 mm | ±1.0 mm | ±1.5 mm | ±1.5 mm | ±1.5 mm |

| Leveling accuracy | <1 mm/m2 | <1 mm/m2 | <1.5 mm/m2 | <1.5 mm/m2 | <1.5 mm/m2 |

| Line speed | 50 m/min | 40 m/min | 40 m/min | 40 m/min | 30 m/min |

| Coil weight | 20,30 t | 20,30 t | 20,35 t | 20,35 t | 20,35 t |

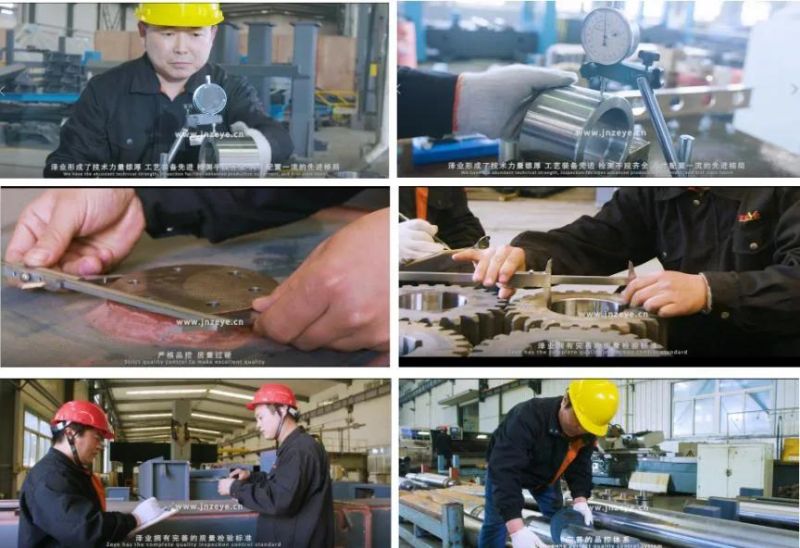

Our Advantages

1..Japan MAZAK, Spain CORREA CNC etc.the world most advanced high precision processing equipment to ensure to produce out the high precision parts.

2. Every part has been done it's own complete technology process, such as forge, rough machined, heat treatment, cooling, burring, tempering, finish turning , milling, drill, thread tapping, match pin, surface quenching,coat the anti-rust oil, fine grinding, test ,entry warehouse, which ensure every part meets it's the best performance

3. Strictly inspection during production and assembly, which in order to ensure every parts to be used is qualified and produce high accuracy shear production lines for end users.

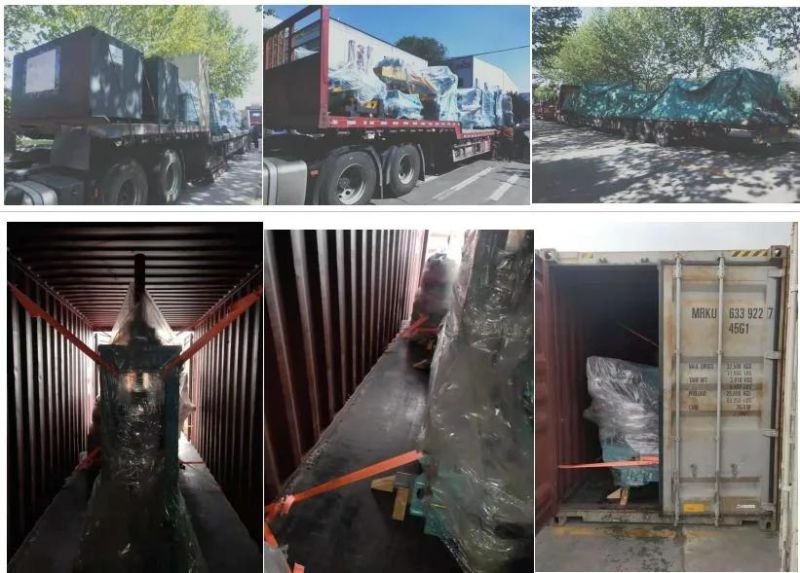

Try Commissionings Before Delivery

For every set of our shear line, which must pass try commissionings and test every part run normally before delivery.

Packing and Delivery

Packing and DeliveryFor the packing requirements, it strictly requires packing with plastic film around the part and equip with the base support of the every parts of our shear lines in order to anti-moisture and fastness, which is suitable for longtime sea transportation and easy to unload when arrive at end user's factory.

Part of Our Customers

Due to enjoy the high reputation of our shearing products, we have supply our cutting lines to POSCO, BAOSTELL, MA STEEL,ANSTEEL, DELONG STEE, SHAN STEEL,SINOTRUCK, CRRC, CHERY, CHANGFENG MOTOR, HRA ,OBON,SIEMENS, MCC, BOSCH, SANDEN etc. famous companies.

Our shear production lines have been exported to Australia, Mexico, Ukraine, Vietnam, Philipines, Uzbekistam, Algeria, Ethiopia, Thainland, Dubai, Sudan, Brazil, Myanmar, Congo etc. 30 countries and areas.

Company introduction

We have two companies, Shandong Zetian CNC Machine Tool Co., Ltd (short for "ZeTian" ) and Jinan ZeYe Machine Tool Co., Ltd ( short for "ZeYe") , ZeTian and ZeYe were founded by Mr.Hu. ZeTian is in charge of handle import and export business, ZeYe is in charge for production, which is located in Jinan city, Shandong Province, China, was founded in 1998.

We have two companies, Shandong Zetian CNC Machine Tool Co., Ltd (short for "ZeTian" ) and Jinan ZeYe Machine Tool Co., Ltd ( short for "ZeYe") , ZeTian and ZeYe were founded by Mr.Hu. ZeTian is in charge of handle import and export business, ZeYe is in charge for production, which is located in Jinan city, Shandong Province, China, was founded in 1998.ZeYe is mainly engaged in developing, manufacturing of Cut to Length Line, Slitting Line, Rotary Shear Line, Moving Shear Line, Slitting and Cut to Length Production Line, Slitting Recoiling or Cut to Length Compound Line and Leveling Machine.

Our products are widely used in plate processing, household appliance, automobiles, pipe mill, mechanical, hardware etc. Industries. It could be application for processing cold and hot rolled steel, carbon steel, galvanized steel, silicon steel, tinplate, stainless steel, pre-painted steel, aluminum, copper and other metals.

We have one professional technical team and after sales service teams, we are ready to serve you at any time.

Welcome to visit our factory.

FAQ

Q: Could you produce the shear line as per our specific requirements?

A: Yes, we are a professional manufacturer specialized in automatic shearing line

for 23 years, we have a strong design & technical team, we can design and manufacture as your requirements.

Q: How to get an accurate quotation ?

A: Please provide us the detailed requirements, such as coil weight, material, width range, thickness range,shearing length, processing precision etc.

Q: What's the MOQ, warranty... ...

A: MOQ: 1 set.

Warranty: 12 months after commissionings of equipent is qualified.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23