300L 500L 1000L 2000L 3000L 4000L 5000L 7bbl 10bbl Large Brewery Turnkey Service ...

Hangzhou Panache Import and Export Co., Ltd. / 2022-07-04

- Voltage:220V

- Customized:Customized

- Condition:New

- Warranty:12 Months

- After-sales Service:Whole Life

- Composition:Beer Brewing Equipment

=== Base Info ===

- Bright Beer Tank:Yes

- Fermentation:Low Temperature

- Inner Tank:3mm

- Insulation:80mm Polyurethane

- Cladding Thick:2mm

- Pressure Gauge:Psi MPa

- Manhole:Side or Upper

- Pipes:Stainess Steel Material

- Connection:Tri-Clamps

- CIP Ball:Washing Ball

- Controller:PLD or Touch Screen

- Cooling Way:Steam Jacket

- Malt Crushing:1000kg,H Grinder

- Heating Way:Steam Generator

- Process:Ferment

- Processing Material:Ss 304

- Model NO.:CJ-4000

- Beer Filling System:Kegging Bottling or Canning

- Transport Package:Container

- Specification:CJ-4000

- Trademark:CJ brew

- Origin:China

- HS Code:8438400000

=== Description ===

Basic Info.

Model NO. CJ-4000 Processing Material Ss 304 Process Ferment Heating Way Steam Generator Malt Crushing 1000kg/H Grinder Cooling Way Steam Jacket Controller PLD or Touch Screen CIP Ball Washing Ball Connection Tri-Clamps Pipes Stainess Steel Material Manhole Side or Upper Pressure Gauge Psi MPa Cladding Thick 2mm Insulation 80mm Polyurethane Inner Tank 3mm Fermentation Low Temperature Bright Beer Tank Yes Beer Filling System Kegging Bottling or Canning Transport Package Container Specification CJ-4000 Trademark CJ brew Origin China HS Code 8438400000Product Description

300L 500L 1000L 2000L 3000L 4000L 5000L 7BBL 10BBL Large Brewery Turnkey Service Commercial Bar Pubs Beer Brewing Equipment Price

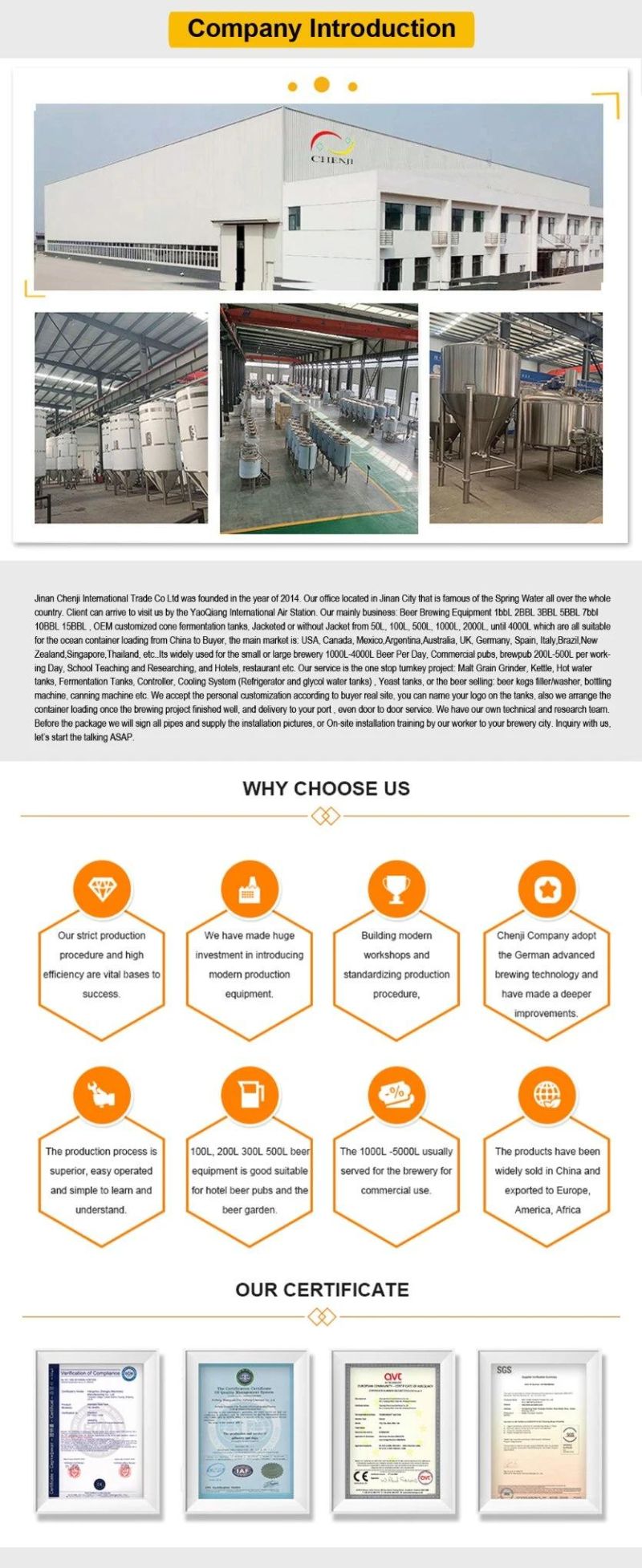

Jinan Chenji International Trade Co Ltd was founded in the year of 2014. Our office located in Jinan City that is famous of the Spring Water all over the whole country. Client can arrive to visit us by the Jinan YaoQiang International Air Station.

Our mainly business: Beer Brewing Equipment 1bbL 2BBL 3BBL 5BBL 7bbl 10BBL 15BBL , OEM customized cone fermentation tanks, Jacketed or without Jacket from 50L, 100L, 500L, 1000L, 2000L, until 4000L which are all suitable for the ocean container loading from China to Buyer, the main market is: USA, Canada, Mexico, Argentina, Australia, UK, Germany, Spain, Italy, Brazil, New Zealand, Singapore, Thailand, etc..

Its widely used for the small or large brewery 1000L-4000L Beer Per Day, Commercial pubs, brewpub 200L-500L per working Day, School Teaching and Researching, and Hotels, restaurant etc. Our service is the one stop turnkey project: Malt Grain Grinder, Kettle, Hot water tanks, Fermentation Tanks, Controller, Cooling System (Refrigerator and Ice water tanks) , Yeast tanks, or the beer selling: beer kegs filler/washer, bottling machine, canning machine etc.

We accept the personal customization according to buyer real site, you can name your logo on the tanks, also we arrange the container loading once the brewing project finished well, and delivery to your port , even door to door service.

We have our own technical and research team. Before the package we will sign all pipes and supply the installation pictures, or On-site installation training by our worker to your brewery city.

Inquiry with us, let's start the talking ASAP.

What's Your Brewing Plan?

To offer you the suitable equipment with favorable price, would you please help confirming the following:

- What is your area for the project?

2. What about your local Power supply? 220v 1p 50hz, 380v 3p 50hz,220v 3p 60hz ?

3. What about your time plan ? Usually the production need 35-50 Days

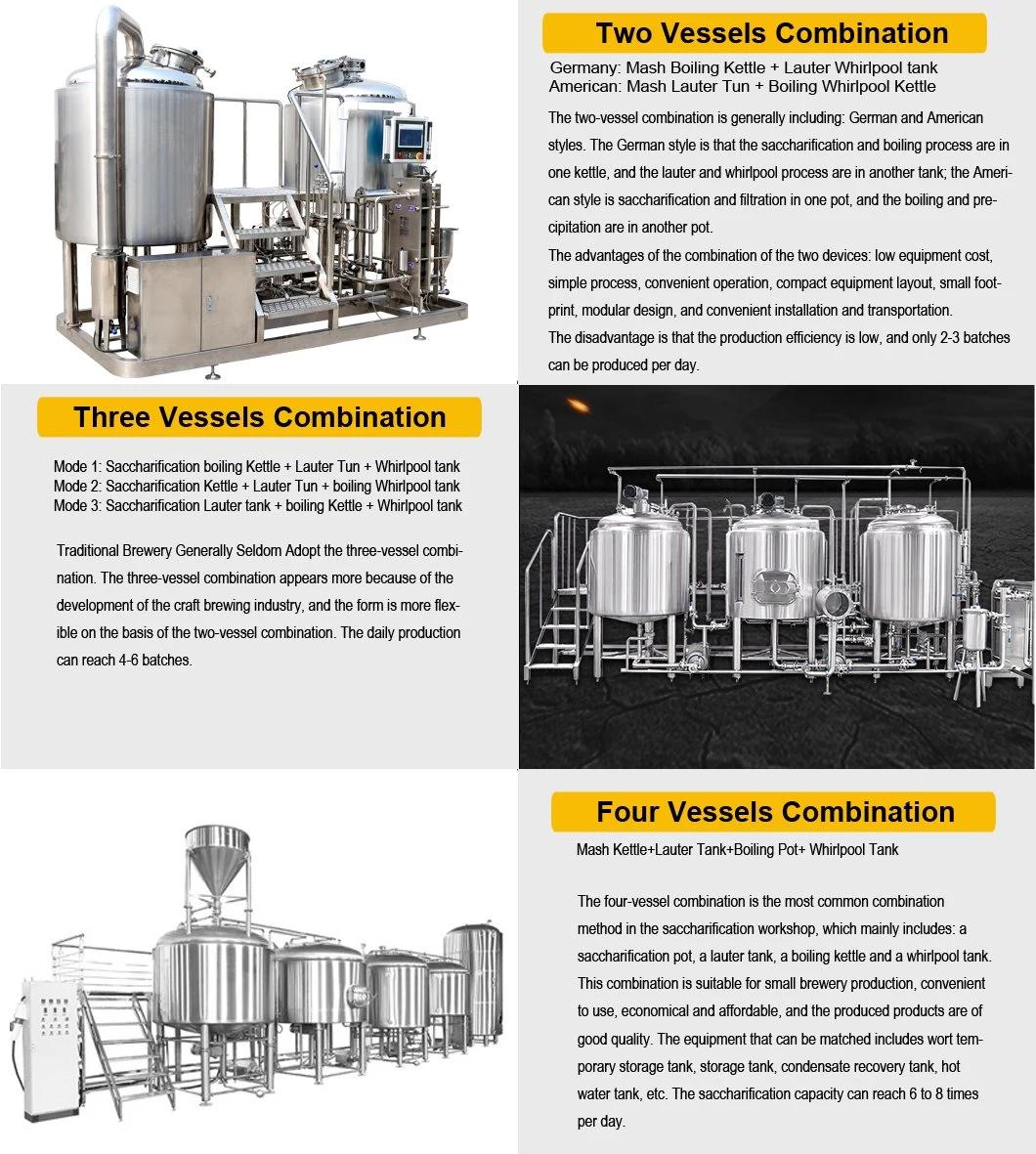

4. You need the Brewhouse with 2 or 3 vessels type ? or others?

5. How many Fermentation Tanks Needed ? 1:1 or 1:2

6. Would you like to with the Bright Tanks too?

- Where will be the nearest destination Port if you need to know the freight cost ?

- Would you need the electric appliance with UL or others certificate ?

- Would you need our engineer to your city for installation and brewing train ?

Our Service

- Customized according to your personal request based on our standard configuration

- After Sale Service for whole life if you have request

- 24hours on line, supply solutions any time

- 3 Years Warranty for the Main Equipment

- Spares parts replacement and repair service

- Engineer goes to your city for installation, debugging and brewing training if you need

- Provide the import documents that you need for customs clearance and reduce Tax.

- Supply the latest news for the brewing industry and brewing technology

- Port to Port, Door to Door service

FAQ:

1.Q: Are you professional Supplier and tanks Manufacture ?

A: We are the manufacturer of beer brewing equipment for 15 Year and deal in export business since 10 years ago .

2.Q:Can I have the customized products with personal design?

A:Yes,we support any of your wish design,can design and manufacture as client's requirements.

3.Q: Can you guarantee your beer brewing system quality?

A: All of the equipment will be inspected before the package, appliance of the international Standard.

4.Q:How about the after sales service?

A:For our after-sale service, we promise all life of technical support to all client.

All of our products is available with 10 years warranty even for spare parts within quality warranty period, our service is free of charge.

5.Q: Which export port you use?

A:Commonly we will use Qingdao port, sometime, can be other port as your wish.

6.Q: I am green hand in brewery industry? Could you supply training for us?

A: Yes, our engineer can supply the installation equipment and brewery training service overseas.

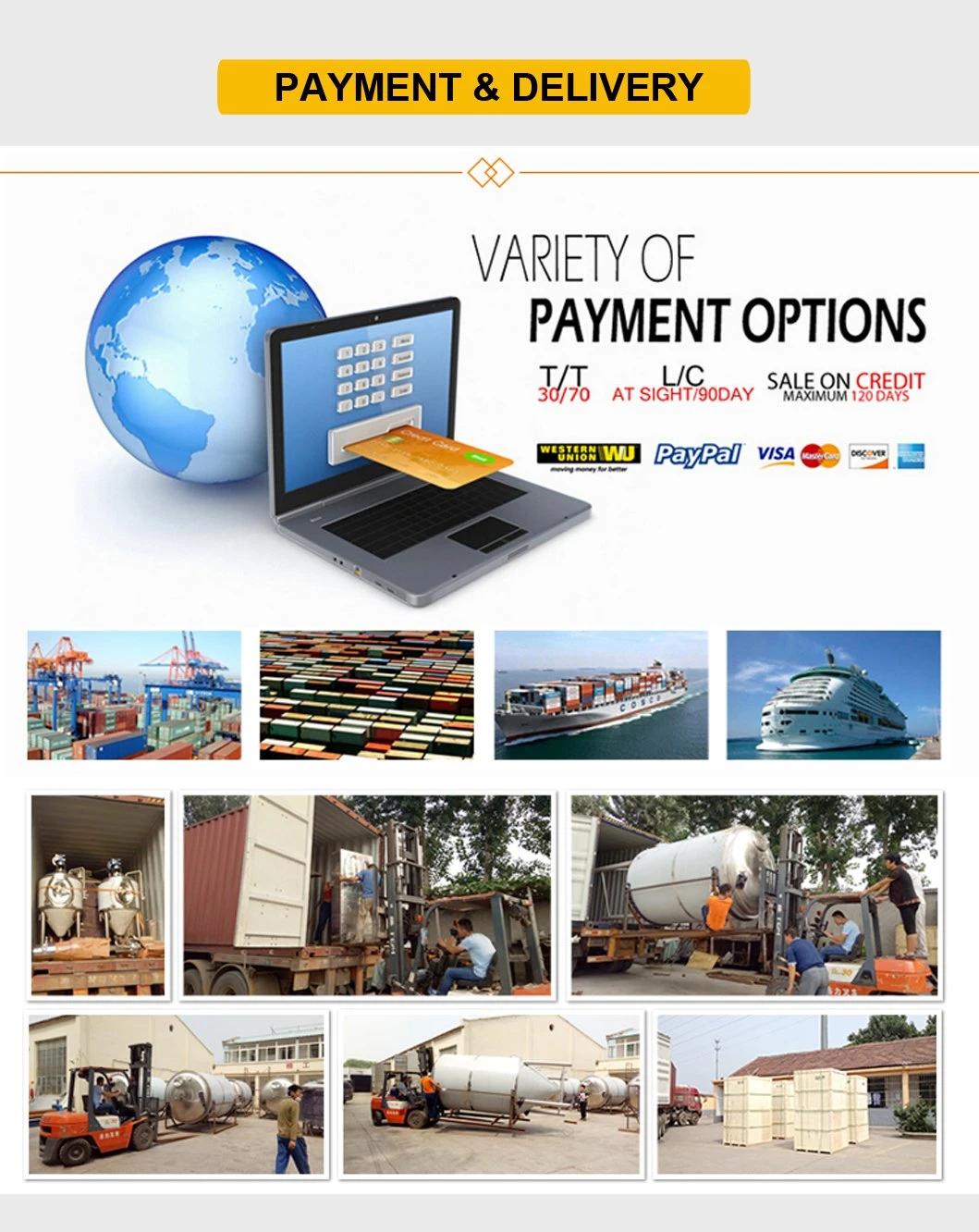

7.Q: what is your payment item ?

A: We accept 40%TT + 60%TT as for the balance payment before the delivery

we are supplier of beer brewing equipment, web is www.made-in-china.com/showroom/chenjibusiness

Preponderance:

1.Luxurious shape, small space requirement, not only has the ornamental value, but also can display the whole process for customer brewing. 2.High degree of mechanization: mechanization of production jobs, reduce the labor intensity of work. 3.High degree of automation: temperature, humidity, airflow monitoring can be achieved, based on the saccharification technology requires automatic control, and provides a more comfortable environment for wine embryo growth; PLC programming, touch screen operation, may at any time modify the saccharificaion technology parameters, record the whole production process data, for the query. 4.Brewing out of beer and tastes purer, more rich nutrition, more juice taste, kill mouth stronger, crisp and delicious, foam white and delicate, has strong malt fragrance and sweet wine.

5.We have a large number of professional and technical personnel and advanced equipment, realize intensive production methods and the high quality of the scale of the production line, ensure high quality and low cost, unique beer and low cost make you quickly develop market and seize the market.

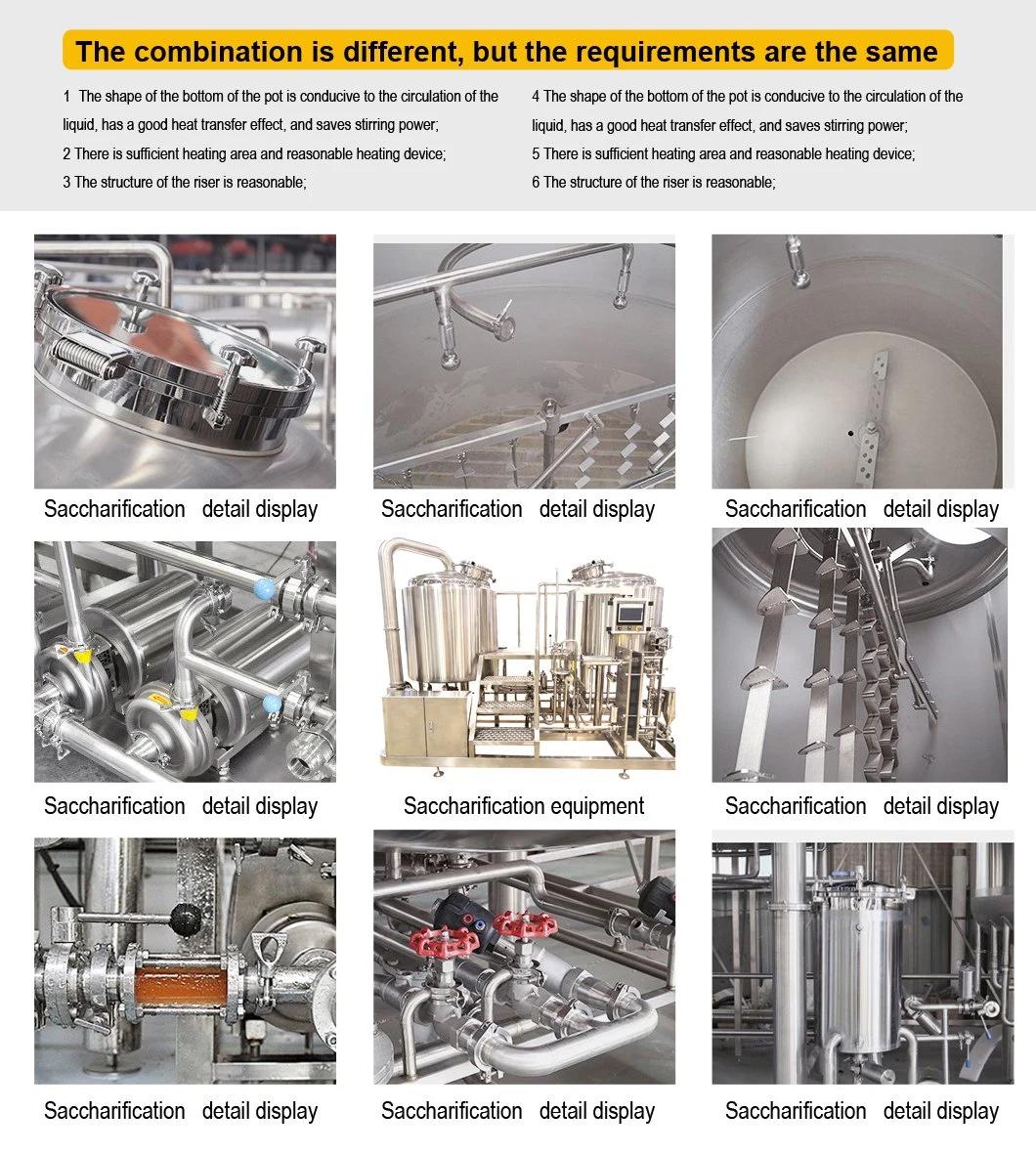

6.Jinan ChenJi company supply beer equipment, mashing equipment uses the design of a pot of two slots and two styles,

Equipment and piping layout are beautiful and, easy to operate and safe.

Pipelines between equipment-apply healthy and quickly connection. The dismantlement, asseming and move, and the transformation-of the pipelines are convenient..

7.The main equipment are adjustable, stable, no running, drop, leakage, no steam were leaked. It has perfect CIP cleaning and sterilizing system, equipment, washing is convenient,and thorough.Equipment and piping layout have no dead Angle, can achieve aseptic operation. All plank, pipes and pipe fittings, valves use advanced healthy materials, the water containers, pipes and pipe fittings all use SUS304,which can be contact directly with the malt, beer, cleaning agents, material.

8.All the gasket adopt the sanitation.Four fluorine ethylene material. It uses the beverage pump of anti-acid , anti-alkali, anti-high temperature, and lower oxygen pressure. The equipment is processed finely, precision of welding and connection reaches hygienic standard internal using mirror

polishing, the external use stainless steel smooth processing.

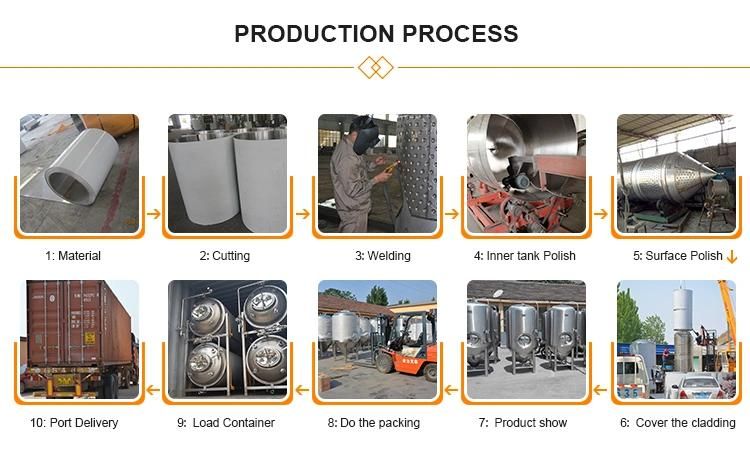

Beer brewery equipment, fermenting tanks, mash lauter tun and brew kettle are packaged by pearl wool around, need 2x40feet high container by pearl wool around

1 - When Delivered by LCL (Less Container Loading), The tank will be covered by Pearl Wool, then Packed in Wooden case !

2 - When Loaded in Whole Container, The tank will be covered by Pearl Wool, Lay down & fixed on a Iron frame, finally the whole tank will be fixed in the container !

3-Providing beer production technology, brewing formula and person training service;Make layout of your plant and installation the equipment; Main machine guarantee for 3 years, all life service.

We have a high efficiency after-sales service team. As a professional beer equipment supplier, we regard after-sale service as important as equipment quality, especially for international customers.

1. We dispatch our engineer to help you install the equipment and teach you how to operation at your local site.

2. Customer can ask for engineer dispatching service not only at installing, training and debugging, also at the whole working life of the machine we delivery.

3. The engineer will come to the agreed place at the confirmation of After-sale Department, and no longer than 10days after all the documents include Visa and air ticket finished.

4. All the main equipment are of 3 years' warranty and all life services.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23