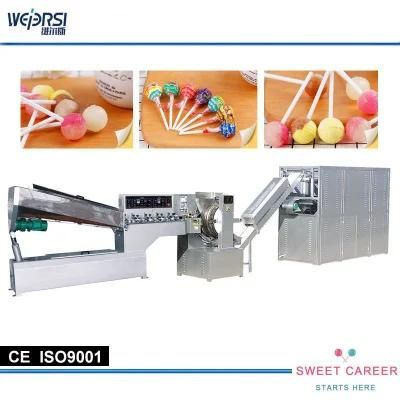

Qb-528 Ball Lollipop Making Line

Shandong Jiangnan Plastic Industry Co., Ltd. / 2022-07-05

- Processing Material:Sugar,Glucose

- Application:Candy

- Customized:Non-Customized

- Certification:CE, ISO9001, Ce, ISO9000

- Power Source:Electric

- Automatic Grade:Automatic

=== Base Info ===

- Model NO.:QB-528

- Size:Diameter 18~35 mm

- Capacity:500~700PCS,Min

- Machine Color:Silvey Gray or Cream

- Output:4t,8hours

- Deliever Time:50 Days

- Payment:T,T, L,C

- Transport Package:Wooden Packing

- Specification:CE

- Trademark:WEALTH

- Origin:Rugao City of Jiangsu Province

- HS Code:8438200000

- Production Capacity:50 Sets,Year

=== Description ===

Basic Info.

Model NO. QB-528 Size Diameter 18~35 mm Capacity 500~700PCS/Min Machine Color Silvey Gray or Cream Output 4t/8hours Deliever Time 50 Days Payment T/T, L/C Transport Package Wooden Packing Specification CE Trademark WEALTH Origin Rugao City of Jiangsu Province HS Code 8438200000 Production Capacity 50 Sets/YearProduct Description

The plant, with many advantages of compact structure, reliable performance and high level of automation, consists of heat-proof pulling device for hard candy, molding machine, cooling conveyor, wrapping machine, etc. The pressing-style mold can ensure plump shape for lollypop and reliable stick inserting. With waggling cooling conveyor, there is less distortion resulting in perfect lollypop surface. To form a complete set production line there should be 2 sets of BBJ-II spherical lollipop wrapper.

| Name | Quantity | Weight (kg) | Size (mm) |

| Sandwich sugar pot | 2 | 220 | 1100*1200*1450 |

| Syrup pump | 1 | 50 | 600*100*200 |

| Storage cauldron | 1 | 100 | 600*600*1200 |

| Vacuum cooker | 1 | 400 | 1700*1000*2200 |

| Cooling table | 2 | 100 | 2000*1000*800 |

| Batch roller | 1 | 800 | 2500*750*1650 |

| Rope size | 1 | 800 | 1500*680*1350 |

| Forming machine | 1 | 1000 | 2250*1000*1600 |

| Cooling tunnel | 1 | 4000 | 9000*1950*1980 |

| Lollipop packing machine | 4 | 1000*4 | 2400*1000*1800 |

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopt frequency converter,make the plant work consistently.

3) Forming mould use pressing board type,ensure the candy forms satiation,and stick position accurate.

4) Use the waggling sieve to cool and convey lollipop,avoid the candy shape from distortion and stick accurate.

5)Adopt double screw revolve to extrude the material,make the bubble gum even,keep center filled material of the bubble gum even and consistent.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23