Automatic CNC Welder Equipment Fiber Laser Welding Machine for Tee Coupling Stainless Steel Flume

Zhejiang Lanmen Co., Ltd / 2022-06-23

- Application:Electronic Industry, Automotive Industry, Manufacturing Industry

- Technical Class:Continuous Wave Laser

- Control:Automatic

- Power Density:Heat Conduct Welding

- Laser Classification:Optical Fiber Laser

- Type:Portable Welding Machine

=== Base Info ===

- Model NO.:KH-L10

- Welding Materials:Metal

- Laser Power:1000W

- Laser Source Brand:Raycus

- Positioning:Red Light

- Output Stability:Less Than 3%

- Laser Focus:200mm

- Max Modulation Frequency:20kHz

- Cooling System:Water Cooling

- Certification:Ce

- Working Temperature:10-40 C°

- Transport Package:Logistics Wooden Box

- Specification:600mm *1060mm *1060mm

- Trademark:Kahan

- Origin:Zhejiang, China

- HS Code:8515809090

- Production Capacity:50 Sets, Month

=== Description ===

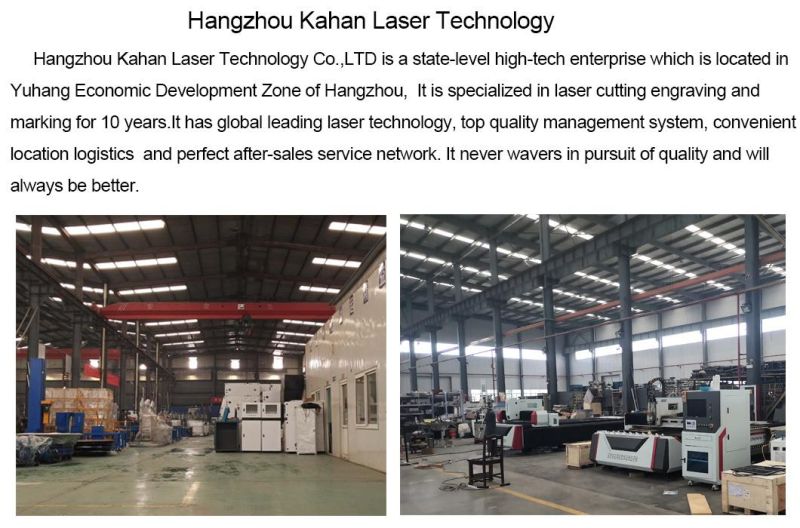

Handhold Fiber Laser Welding Machine

Advantages:

1.The laser welding machine adopts 1000 watt fiber laser, which has high photoelectric conversion efficiency and long life of 100,000 hours. The energy provided by electric energy is 25%-30% converted into laser energy, and the photoelectric conversion rate is many times than that of YAG laser.

2.The energy density is high, the heat input is low, the amount of thermal deformation is small, and the melting zone and the heat-affected zone are narrow and deep.

3.High cooling rate, which can weld fine weld structure and good joint performance.

4.Compared with contact welding, laser welding eliminates the need for electrodes, reducing daily maintenance costs and greatly increasing work efficiency.

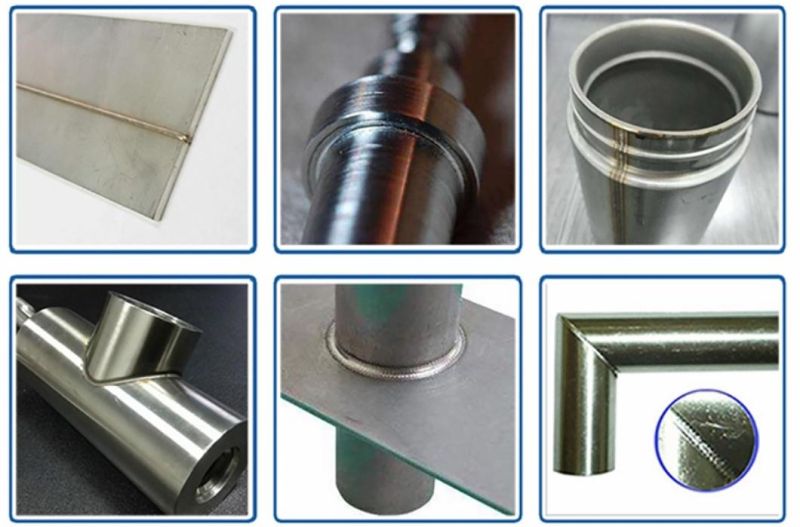

5.The weld seam is thin, the penetration depth is large, the taper is small, the precision is high, the appearance is smooth, flat and beautiful.

6.No consumables, small size, flexible processing, low operating and maintenance costs.

7.The laser is transmitted through fiber optics and can be used in conjunction with a pipeline or robot.

Application:

It is widely used in the automotive, machinery manufacturing, medical equipment, shipbuilding, chemical industry, aerospace, aviation, power battery and daily necessities industries.

Configuration:

Packaging & Shipping

1. Kahan CNC machine and accessories are covered by plastic sheet first.

2. Then the whole machine is packed by plywood case used for export.

3. Kahan CNC machine can be delivered by sea, by train, or by plane depending on customers.

Delivery Detail:

Shipped in 15-30 working days after payment.

Guarantee:

2 years warranty for the whole machine. Within 24 months under normal use and maintenance, if something is wrong with the machine, you will get spare part for free. After 24 months, you will get spare parts at cost price. You will also get technical support and service all the lifetime.

Technical support:

1. Technical support by phone, email or WhatsApp/Skype around the clock.

2. Friendly English version manual and operation video CD disk.

3. If needed, we can send our engineer to your site for training or you can send the operator to our factory for training.

After sales services:

Normal machine is properly adjusted before dispatch. You will be able to use the machine immediately after received machine. Besides, you will be able to get free training advice towards our machine in our factory. You will also get free suggestion and consultation, technical support and service by email/WhatsApp/tel etc.

FAQ for Laser Cutting Machine:

Q: There are so many machine types, which one should I choose?

A: Kaihan Laser provides machine parameters in each product demo page, please kindly check technical data column. It is important to compare all data before choose the best prototype. Also, our sales team provides online services to resolve your confusion, feel free to contact us.

Q: This is my first time buying your machine; I have no ideas about Kaihan's machines quality?

A: Each machine is strictly produced based on the standard of ISO9000-2000, ISO14001-2004, GMC global manufacturer and CE certifications. Our products have CE certifications verified by TÜV SÜD, Bureau Veritas and etc. As china high-power laser cutting machine provider, more than 10,000 machines have been sold in the past ten years. Customer is our first priority. We are confident to tell customers that there is no need to worry about our quality.

Q: When I got this machine, but I don't know how to use it. What should I do?

A:There are video and English manual with the machine. If you still have some doubts, we can talk by telephone or email.

Q: If some problems happen to this machine during warranty period, what should I do?

A: We will supply free parts during machine warranty period if machine have some problems. While we also supply free life long after-sales service. If you have any question,just contact us freely.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23