Plastic PVC WPC Crust/Celuka Foamed Board Extrusion Machine

Hangzhou Harpow Tools Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

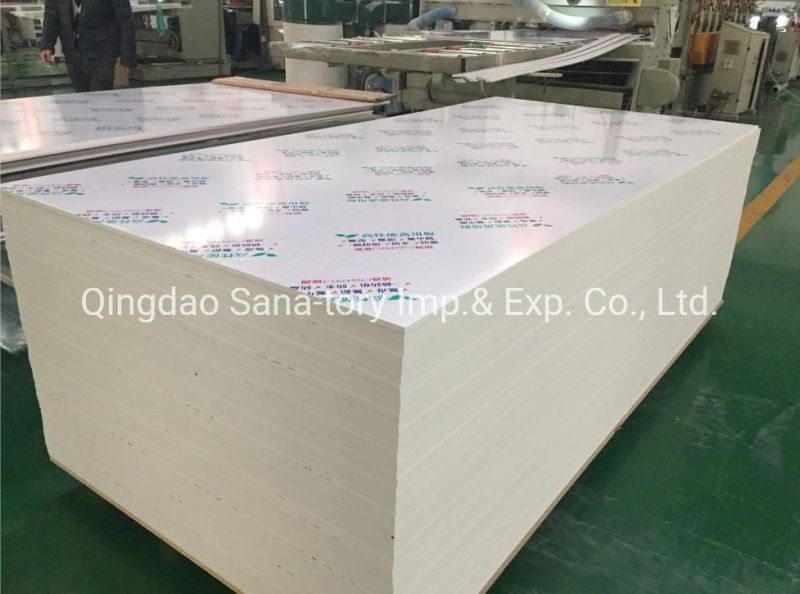

Model NO. ST-80 Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Non-Computerized WPC Celuka Panel Extruder Conical Twin Screw Extruder Long use life Full automatic Transport Package Wooden Specification CE Trademark Sana-tory Origin China HS Code 84778000 Production Capacity 450kg/HProduct Description

Plastic PVC Wood WPC Crust/Celuka Foamed Board Extrusion MachineFeatures of the production line:

1)The twin screw plastic extruder is a highly effcient agglomerating and extruding equipment.

2)Extrusion machine of this series feature low shesring rate, uneasy degradtion, even plastiction and agglomeration, reliance quality, wide application range and long servicing life.

3)Using PVC or PE/PP and wood powder as raw material for direct forming, the extruders perform an excellent effectiveness.

4)This PVC WPC sheet or board production line has automatic temperature control, vacuum gas exhaustion, olicooled screws, stepless speed regulation, as well as aforced feeding and self-cleaning machianism.

5)This extruding machine has many usages. With appropriate extruding heads, screws and other auxiliaries, they are able to directly convert plastic and wood powder into WPC board.

Our plastic sheet extrusion and board extrusion line are designed to be tailored to your specific product and process requirements, to help you achieve lasting business success.

| Machine Type | SJ80/156 | SJ92/188 |

| Product Width | 915-1220mm | 1830mm |

| Product Thickness | 3-20mm | 5-35mm |

| Extruder Specification | SJZ80/156 | SJZ92/188 |

| Max. Extrusion Volume | 400kg/h | 650kg/h |

| Main Motor Power | 75kw | 110kw |

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23