Automatic Plastic/Pet Bottle Blow/Blowing/Making Molding Machine

Dongguan YUSHUNG Plastic Electronics Co., Ltd. / 2022-07-04

- Condition:New

- Customized:Customized

- Voltage:380V

- Composition:Blow Molding Machine

- Processing Material:Stain Steel

- Process:Fine Precise

=== Base Info ===

- Model NO.:ESM-3-1500

- Type:Stretch Blow Molding

- Material:Stain Steel

- Application:200ml to 1500ml Bottle

- Power:18kw

- Warranty:One Year

- Transport Package:Wooden Packaging

- Specification:10-12 square meter

- Trademark:ES AQUA

- Origin:China

- HS Code:8477309000

- Production Capacity:2200bph, 5 Sets , Month

=== Description ===

Basic Info.

Model NO. ESM-3-1500 Type Stretch Blow Molding Material Stain Steel Application 200ml to 1500ml Bottle Power 18kw Warranty One Year Transport Package Wooden Packaging Specification 10-12 square meter Trademark ES AQUA Origin China HS Code 8477309000 Production Capacity 2200bph, 5 Sets / MonthProduct Description

Automatic PET Bottle Blow Molding MachineA. Product Description:Model :ESM-3-1500 (3 cavity)

Production capacity :2200BPH

Application range : 200ml to 1500ml

Pls Note : This model machine can not be connected Air conveyor

Features

ES series is one kind of two-step automatic PET bottle blow moulding machine,which is suitable for blowing any shape of PET bottles such as carbonated water bottles, water bottles, juice bottles, oil bottles, cosmetic containers,etc.

1.The machine adopts human-computer interface to control the whole working procedures, auto-loading, auto blowing, auto dropping. Action cylinders are all assembled with magnetic induction switches.Connect with PLC to control every step and test every cylinder. Next action will continue after the former step done, If former step is not finished, alarm automatically and do not work. PLC displays problem position.

2.Fast speed, accurate position, smooth action.

3.According to special demand, adopt cross double crank pressed clamping, with strong clamping force. Mould open stroke can be adjustable according to the bottle size to save the time.

4.Far infrared heater lamps have strong penetrations , are heated uniformly while rotating, PLC or electronic pressure adjustor controls each group of temperature separately.

5.Particular pre-heater design makes close while heating. Change space, shorten heating tunnel and reduce energy consumption according to the bottle size while blowing.

6.The air supply system consists of slight blow, high pressure blow, low pressure actions, to supply enough air for different products.

7.Special recycling installation for high pressure air reduce the energy consumption.

8.Operation consists of manual and automatic procedure, manual operation for assembly and test, automatic operation for production.

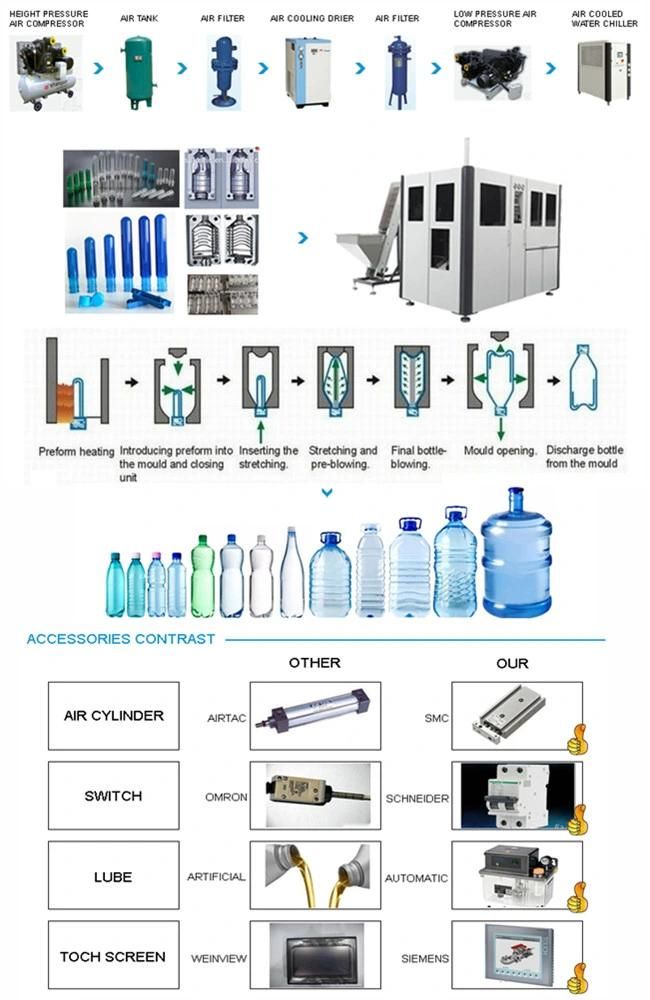

Flow Chart:

Origin of ES SERIES blow molding machine's components:

| Item | Name of the main spare parts | Brand Name |

| 1 | Closing cylinder | SMC |

| 2 | Stretching cylinder | SMC |

| 3 | Moving cylinder | SMC |

| 4 | Mold lifting cylinder | SMC |

| 5 | Closing magnetic valve | SMC |

| 6 | Stretching magnetic valve | SMC |

| 7 | Blowing magnetic valve | SMC |

| 8 | Moving magnetic valve | SMC |

| 9 | Voltage regulator | Germany SIEMENS |

| 11 | Computer controller | Germany SIEMENS COLOR touch screen |

| 12 | Computer checking switch | Germany SIEMENS |

| 13 | Infrared lamp | CHINA philips |

| 14 | Moving valve | SMC |

| 15 | Open circuit controller (32A) | Germany SIEMENS |

| 16 | Heat continue controller (24A/220V) | Germany SIEMENS |

| 17 | Magnetic switch | Germany SICK-Sensor |

| 18 | Photoelectric switch | Gernmany SICK-Sensor |

Related Products:

B. Packaging & Shipping:

C. Company Information:

ES AQUA LTD is engaged in professionally researches, develops and manufactures beverage-packaging machinery and dairy packaging machinery. We bought several sets numerical control machines from American and Japan. The fixed assets of ESAQUA exceed USD 50 million. Since its foundation, ES AQUA has concentrated on a single area of beverage and water product packaging machinery. Recently, we already finished some researches and were going on some project, including "automatic high speed aseptic filling machine of liquid food", which is the state torch program, "mono-block filling machine of juice with pulp", "liquid milk & beverage continuous high-speed packing robot" etc. We took part in national standard making, and then we became the leader in the industry. Moreover, we cooperated with foreign and domestic famous enterprises, such as Pepsi, Bright Dairy, Robust, etc, also our products are exported to all over the world. The company always hold the philosophy of "the quality wins the market, the brand forms the success". We, full of enthusiasm and sincerity, warmly welcome domestic and overseas customers.

Main product of ES AQUA:

- The capacity is from 2000BPH to 36000BPH for hot filling, mid-temp filling, and aseptic cold filling lines.

- The capacity is from 2000BPH to 36000BPH for mineral water and pure water product line.

- The capacity is from 2000BPH to 20000BPH for carbonated beverage product line.

- The capacity is from 8000 to 15000 packs per hour for brick pack of aseptic milk packaging product line.

- The capacity is from 2000BPH to 30000BPH for beverage with particle product line.

- There are water treatment equipments.

- PET blow molding machine

- Beverage pre-blending and sterilizing system

D. Our Services:

What service ES AQUA LTD can offer you?

Your inquiry related to our product & price will be replied within 12 hours.

Well-trained & experienced staff are to answer all your inquiries in English and Chinese.

Working time: 8:00am ~10:00pm, Monday to Saturday(UTC+8).

OEM & ODM projects are both available.

Your business relationship with us will be confidential to any third party.

Good after-sale service offered, please get back to us if you got any questions.

After Sales Service

One year warranty for the whole system .

Free equipment installation and debugging.

After one year , we can help you to maintain the machine and the accessories are provided

only one the cost price.

We can provide internship service and help you train the operator and mechanic.

Free production technology and process configuration.

We can help you to design the product line , workshop and provide turn-key project.

E. FAQ:

1.Do you supply Free samples (preform or cap)?

A: Yes, we can provide you free sample if there are in stock,but we don't include the delivery charge.

2. Can your factory provide the whole plant from A to Z?

A: Yes, we can provide a complete plant from blowing plant , water purification plant to filling & packing plant.

3. Are all machinery your factory made?

A: Yes, Our factory made the water purification plant and filling & packing plant, we do not make the bottle making machine, but we have good quality bottle making machine partner, and we can provide to customer same long warranty time and good after service.

4. How can I know the machinery quality before I order?

A: Firstly, we will invite you visiting our factory to cherk the machines quality, and show the machines running for you in our factory

5. What certification you can provide?

A: Our factory can provide the CE,ISO,ETC,which will according to some counties, we also can provide Pvoc,Coc,Soncap…and so on.

6. Can you factory make the bottle drawing, factory layout and label designs for us?

A: We can help customers design their owner bottle shape, workshop and label drawing, there jobs are free charge. (Workshop need customer to provide the size of factory )

7. Installation and Training time

A: We have professional engineer for oversea installation and training who have much experience oversea work.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23