1-20mm Floating Fish Feed Food Making Machine

AIRMAX AL CO., LIMITED / 2022-07-05

- Certification:CE, ISO9001

- Power Source:Electric

- Process:Thermal Processing

- Automatic Grade:Automatic

- Application:Ice Cream, Candy, Chocolate, Popcorn, Chips, Biscuit, Donut

- Customized:Customized

=== Base Info ===

- Model NO.:KS-65,70,85,95

- Voltages:220V,50Hz 380V,50Hz

- Weight:2000-5000kg

- Warranty:1 Year

- Motor:Siemens, LG, ABB, Chinese Brand

- Materials:Stainless Steel

- Transport Package:Wooden Case

- Specification:18000*1200*20000mm

- Trademark:Keysong

- Origin:Shandong China

- HS Code:8438800000

- Production Capacity:50et,Month

=== Description ===

Basic Info.

Model NO. KS-65/70/85/95 Voltages 220V/50Hz 380V/50Hz Weight 2000-5000kg Warranty 1 Year Motor Siemens, LG, ABB, Chinese Brand Materials Stainless Steel Transport Package Wooden Case Specification 18000*1200*20000mm Trademark Keysong Origin Shandong China HS Code 8438800000 Production Capacity 50et/MonthProduct Description

1-20mm floating fish feed food making machine Introduction:Hot sale stainless steel fish food equipment / poultry food making machine / pet feed meal machine

I. Description

Hot sale stainless steel fish food equipment / poultry food making machine / pet feed meal machine uses meat meal, fish meal, corn powder, soya meal and other grains powder as main materials to make the pet food, such as dog, cat, fish, bird food etc. With different shapes and tastes by changing the dies and formulations. The pet foods are made under high temperature condition, and popular to the pet food market.

1.Raw Materials: Meat Meal, Fish Meal, Corn Powder, Soya Meal and Other Grain Powder

2.Products: Pet Food, Like Dog, Cat, Fish, Bird Food etc. with Different Shapes and Tastes by Changing the Dies and Formulations.

3.Capacity: 120-150 KG/H, 200-250 KG/H, 400-500 KG/H, 800-1000 KG/H.

4.Voltage: Three phases: 380V/50HZ, Single phase: 220V/50HZ, we can make it according to customers' local voltage according to different countries.

5.Machines Materials: All the machines are made by food grade stainless steel

Flow chart:

grinding→mixing→extruding→drying→flavoring→cooling→packaging

Raw material:

Rice flour, corn flour, wheat flour, low temperature soya flakes meal, rice bran , wheat bran, fish powder, bone powder etc.

Fish feed product:

fish feed pellet:

floating/sinking

diameter from 0.2mm to 20mm

Fish feed advantages:

In order to meet modern fish farms development, most of modern fish feed is made by twin-screw (or single screw) extrusion production line, which is called expanded, extruded or puffed fish feed.

Adopting cereals, vegetable proteins, vitamins, minerals, fish meal and fish oil as raw materials, and adopting dry-type or wet-type extrusion as manufacturing technique, expanded fish feed is made for both carnivorous and graminivorous fishes.

Compared with traditional fish feed, expanded fish feed has the advantages:

(1) easier feeding management

(2) lower wastage rate

(3) lower water contamination

(4) higher feed nutritional ingredient use ratio

(5) longer storage time. Expanded fish feed improves digestibility and refined the balance of nutrients to match the needs of the different species of fish more precisely at different periods of development. At the same time, expanded fish feed improves the sustainability of the ingredients used. Based on the advantages, expanded fish feed will replace traditional fish feed in the future.

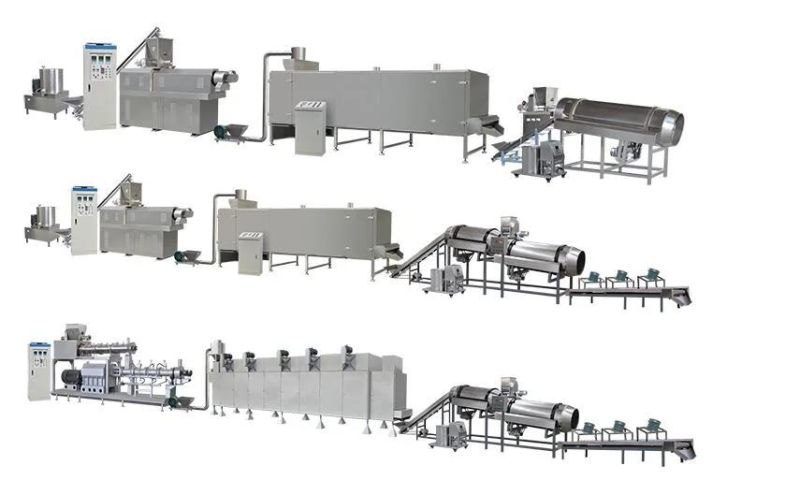

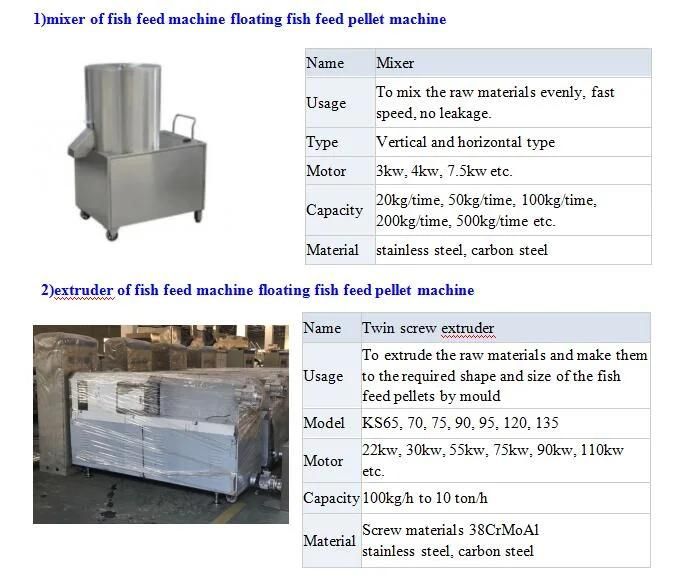

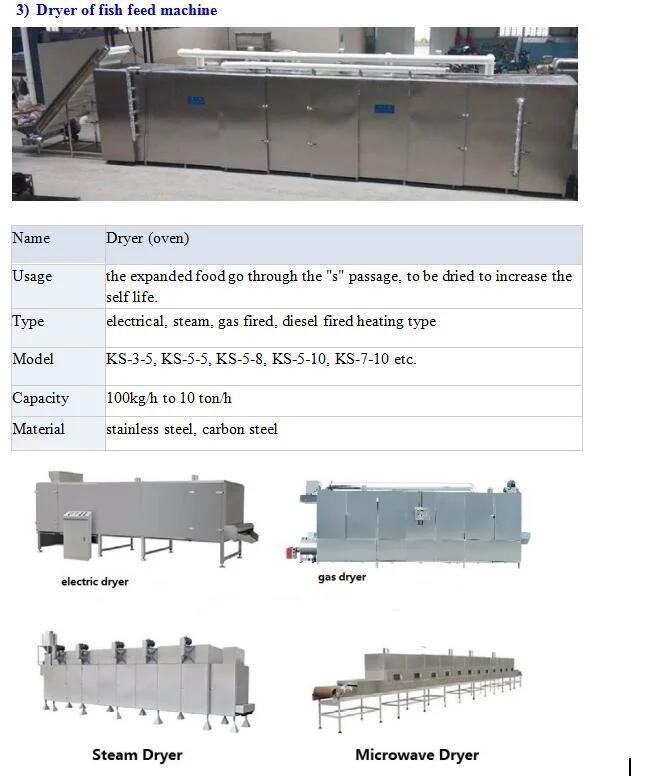

Equipment list in the fish feed production line:

mixer→screw conveyor→twin screw extruder→air conveyor→dryer→hoister→flavoring drum and oil sprayer→cooling machine→packing machine

Technical Parameters:

Technical Parameters:| Model | KS 65 | KS 70 | KS 85 | KS 95 |

| Install Power | 65KW | 110KW | 190KW | 250KW |

| Consumption Power | 42KW | 77KW | 133KW | 175KW |

| Output | 120-150KG/H | 220-260KG/H | 500-600KG/H | 900-1000KG/H |

| Dimension | 19000×1300×2200mm | 22000×1300×2200mm | 30000×1300×2500mm | 38000×1300×3000mm |

Our Factory

Our Team

Our Team

Our clients

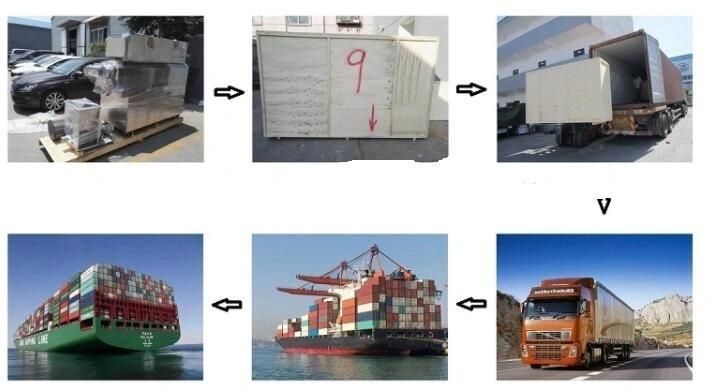

packing and delivery

1. Packing machines into wooden cases;

2. Let trucks take containers to our factory for safely loading;

3. Sending to port for boarding and transportation.

4. We also can send machines by air and train.

Our services:

- Before Purchasing: We will provide professional technical project and sales consultation service to solve the customers' question and worried;

- During Production: Timely updates the machine status for customer to ensure delivery time, and quality;

- After Production: Machine testing video and photos will be provided for inspection, if the customer can't come;

- Before & During Shipment: The machine will be cleaned and packaged before transportation; All the documents will be provided for the custoemrs;

- Installation & Training: Sending professional and expert technical engineers to providing employee training and installation service.

- After Sales Service; Dedicated department and engineers for providing the timely and efficient service when the clients' need, such as formula, parameters setting, spare parts etc;

1 Where is your factory?

Jinan city, Shandong Province, China

2 What is your machine warranty?

1 year, main parts warranty time will be 2 or 3 years.

3 Do you supply spare parts?

Yes, we supply spare parts with reasonable price;

4 What can you provide for after sale service?

We can send engineers to your factory for installation and training if customers' required.

5 If we show you our layout of factory, can you help to design the whole process line?

Yes, our experienced engineers and technical employee can help you to arrange the layout and installation of whole process line based on your real situation;

6 How can we contatc you if we meet problems during production

Phone/email/wechat/whatsapp/Skype are all available.

7 If we have samples of new products, can you help to analysis and design the machine?

Yes, Our technical department can help to analysis, design and test the new products you offered.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23