600 Ml Big Volume Bag-on-Valve for Aerosols Uses

GOLD FORTUNE (GUANGDONG) IMPORT & EXPORT CO., LTD. / 2022-06-09

- Application:Aerosol Cans

- Bag Material:Aluminum Plastic Laminated

- Valve Cup:Aluminum or Metal

- Volume:50ml-600ml

- Material:Aluminum Foil

- Certificates:SGS, ISO9001

=== Base Info ===

- Specification:1 inch

- Transport Package:Standard Export Carton Packing

- Payment Terms:T,T, 30% Prepayment and 70% Balance.

- Delivery Time:10-30 Days

- Packing Terms:with Nylon Bag and Carton

- MOQ:30000 PCS

- Trademark:Gold Fortune

- Origin:China

- HS Code:8481803990

- Production Capacity:600000 PCS , Day

=== Description ===

Basic Info.

MOQ 30000 PCS Packing Terms with Nylon Bag and Carton Delivery Time 10-30 Days Payment Terms T/T, 30% Prepayment and 70% Balance. Transport Package Standard Export Carton Packing Specification 1 inch Trademark Gold Fortune Origin China HS Code 8481803990 Production Capacity 600000 PCS / DayProduct Description

Item Name: Bag-On-Valve* The Application Areas: Bag-on-Valve is a new technology with endless possibilities, and very few limitations. No matter what the application is, Bag-on-Valve increases the performance of your product - whether solution, liquid, gel, creams or ointment.

- Cosmetic

- Pharma & Medical Devices

- Food & Nutrition

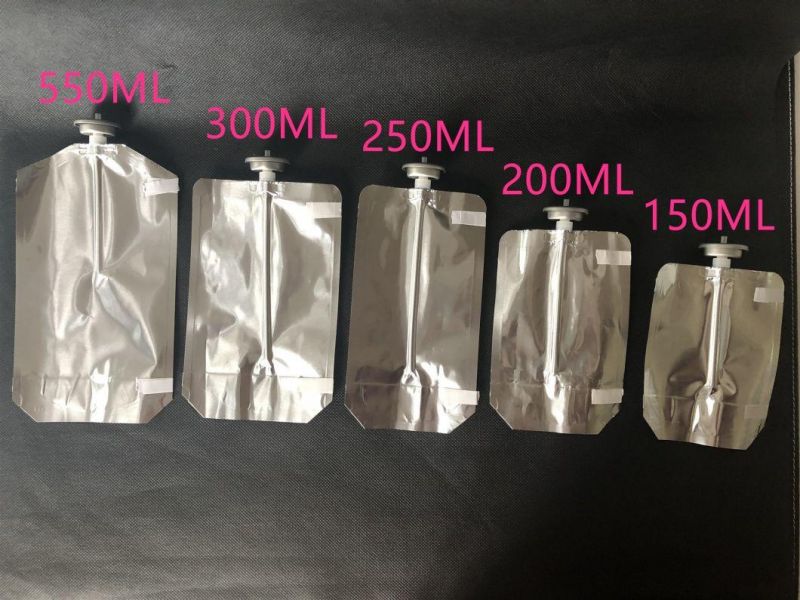

* Size: 100 ML, 150 ML, 200 ML, 250 ML, 300ML,400ML, 450ML, 500ML, 550ML, 600ML..

* Valve Cup: 1 inch Aluminum cup or metal cup.

* Valve style: Male or Female.

Benefits of Bag on Valve Packaging

The unique BoV system is developed to not only produce a superior spray dispensing system, but to reduce our ecological footprint through a sustainable packaging process. Compared to traditional aerosol spray technology (and other alternative packaging) BoV aerosols have several benefits, for manufacturers, consumers as well as the environment.

Safety and environmental benefits of BoV aerosols

- No need for flammable propellants

- Hygienic and sterilisable

- Used with eco-friendly air or nitrogen

- Less need for preservatives

Consumer benefits of BoV aerosols

- Up to 100% product emptying

- Longer shelf life with less preservatives

- Even and controlled spraying pattern for optimal result

- No pumping motion needed

- Can be used at all angles

- Reduced spray noise

- Less-chilling product discharge

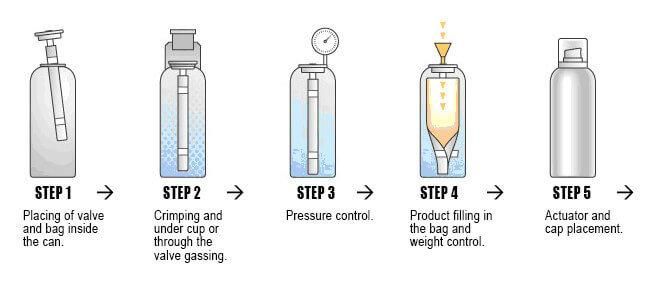

Production and distribution benefits of BoV aerosols

- Longer shelf life for oxygen-sensitive products

- Effective filling process

- Suitable for both liquid and viscous products

- Can be used with standard actuators and aerosol cans.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23