Chinese Factory Refrigerator Crushing Recycling Line

Jiangyin Join Trading Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. Refrigerator Painting Variety of Coating Solutions Transport Package Standard Seaworthy Packing(Wooden Box/ Nude Pack) Trademark 3E Origin ChinaProduct Description

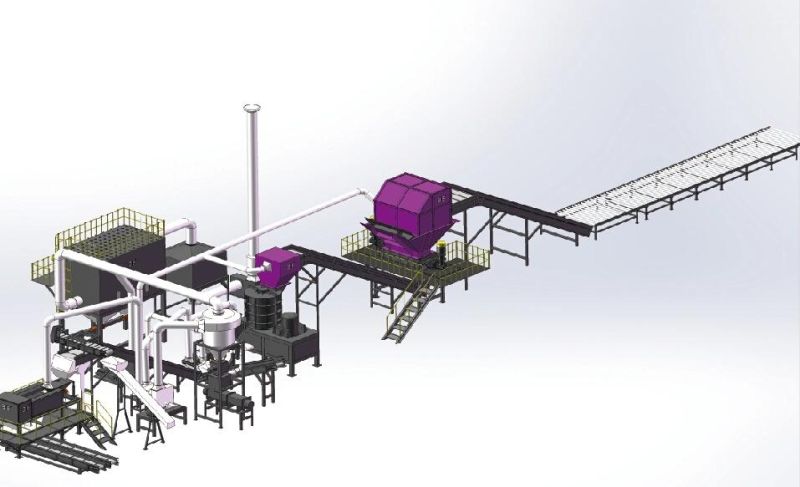

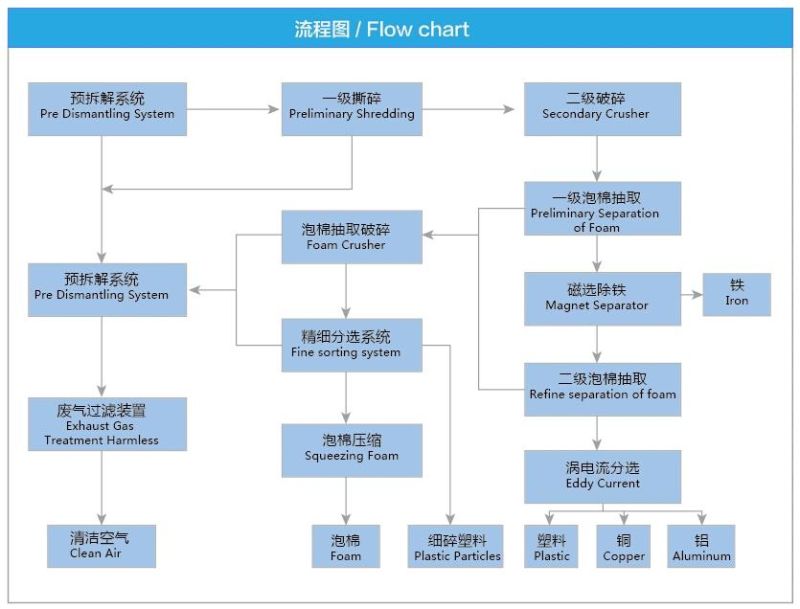

The Waste Refrigerator Recycling Line from Guangzhou 3E Machinery Company is designed to process large volume waste refrigerators. The design for

the recycling line is unique and the separation effect is high. It has already acquired the national patent (ZL2017 1 0005788.9). It is good for environmental

protection and safety production and the output material, dust and exhaust air will be processed by individual ventilation system.

Main Parameter:

Production Capacity: 50-60 units/hour

80-100 units/Hour

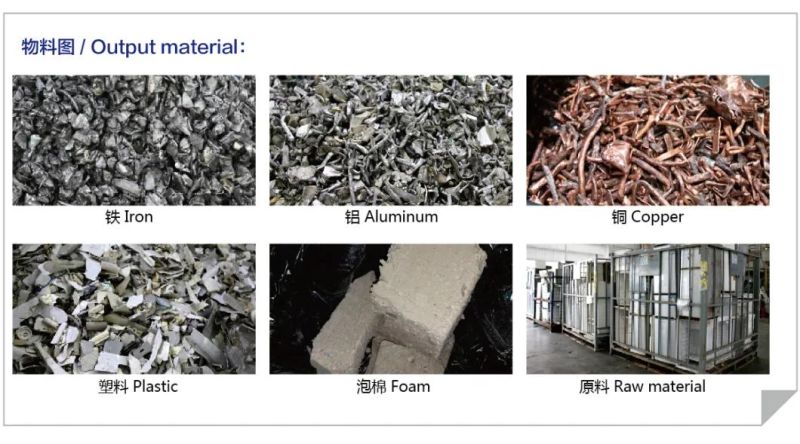

metal separation rate>98%

plastic separation rate >97%

plastic contain foam rate≤1.5%

Foam contain plastic rate≤3%

1. Low power consumption. The separation and crushing

for foam will be finished by high pressure hammer blower

which is self-developed patented equipment.

2. metal density ≥0.8T/M3 the output size of crushed

material is average and separation effect is good.

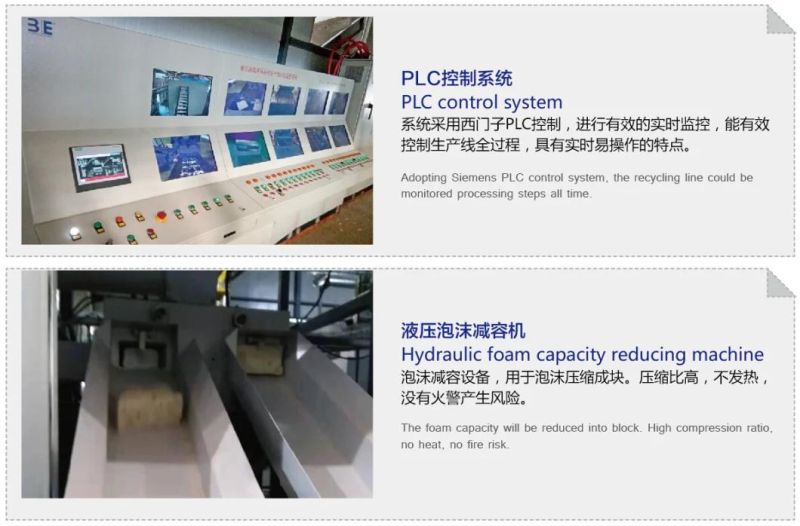

3. Foam volume reduction rate1:8 reduce the volume by

hydraulic pressure, the foam will not get heat avoiding fire risk.

4. It is very suitable for recycle large volume refrigerator and

freezer and separate most part cables automatically.

5.Unique design with national patent (ZL2017 1 0005788.9).

Safety production:

1.It is good for environmental protection and safety production

because the output material, dust and exhaust will be processed

by individual ventilation system.

2.Equipping with nitrogen generator and could make sure to

avoid flash explosion due to the alkenes gas accumulate at

the two shaft shredder operation.

3. Equipped with flammable gas detector and designed with

fire detection alarm, spray and automatic shutdown equipment

and other safety settings.

4. It could meet the customer's requirement to reach remote

monitoring and it is easy to running and maintenance.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23