Commercial Snack Food Pasta Macaroni Spaghetti Making Machine

AIRMAX AL CO., LIMITED / 2022-07-05

- Certification:CE, ISO9001, SGS

- Power Source:Electric

- Process:Thermal Processing

- Automatic Grade:Automatic

- Application:Ice Cream, Candy, Chocolate, Popcorn, Chips, Biscuit, Donut

- Customized:Customized

=== Base Info ===

- Model NO.:KS150

- Capacity:100-500kg,H

- Snack Food Extruder:Single Screw Extruder

- Motor:Siemens

- Inverter:Delta

- Control System:Manual or PLC

- Delivery:15-30 Days

- Warranty:1.5 Years

- After-Sales Service:Commissioning, Site Installation, Training

- Machine Material:Stainless Steel

- Price:Factory Price

- Transport Package:Wooden Case

- Specification:25000*2500*3500mm

- Trademark:KS

- Origin:Shandong, China

- HS Code:8438800000

- Production Capacity:50 Set,Month

=== Description ===

Basic Info.

Model NO. KS150 Capacity 100-500kg/H Snack Food Extruder Single Screw Extruder Motor Siemens Inverter Delta Control System Manual or PLC Delivery 15-30 Days Warranty 1.5 Years After-Sales Service Commissioning, Site Installation, Training Machine Material Stainless Steel Price Factory Price Transport Package Wooden Case Specification 25000*2500*3500mm Trademark KS Origin Shandong, China HS Code 8438800000 Production Capacity 50 Set/MonthProduct Description

Commercial Snack Food Pasta Macaroni Spaghetti Making Machine1. Description

Macaronis pasta noodle making machine adopts potato starch, potato powder and corn starch as main materials, to produce a variety of twice extrusion ones in different shapes, which are popular in the market, such as crispy ea, shell ,screw, square tube, round tube, and wave.This line is characterized by unique technique, rational configuration, high automation and stable performance. It can finish steaming, extrusion and shaping in one step without boiler. The products have similar shapes to the real one and taste crispy and delicious after fried.

2. Features:

Pasta Processing Line is for pasta and macaroni production by single-screw extruder.The raw material can be durum, maize starch, potato powder, potato starch, cassava starch or their mixture, etc. The pasta can be different shapes, like shell, spiral, square tube, etc.

Pasta and macaroni are a semi-manufactured dry product, made of dough, cooked opportunely using extrusion cooking technology, shaped and formed until reaching a humidity of less than12%.This product is extremely compact, (apparent density of 300-400 g/l, 10 times higher than that of the finished product) occupies little space and can be easily preserved for over a year in normal environment conditions, without particular packaging.

3. Raw materials

adopts potato starch, corn starch, cassava starch, wheat flour, corn flour etc as raw materials

4. Products

This line can be used to produce different shapes of pellets by adjusting the moulds from extruder;

5. Capacity

100-120 kg/h; 280-300kg/h

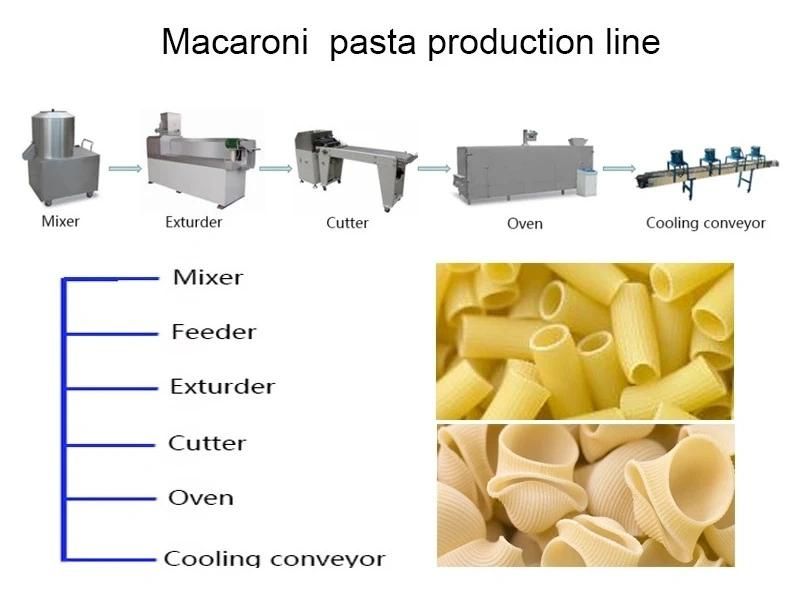

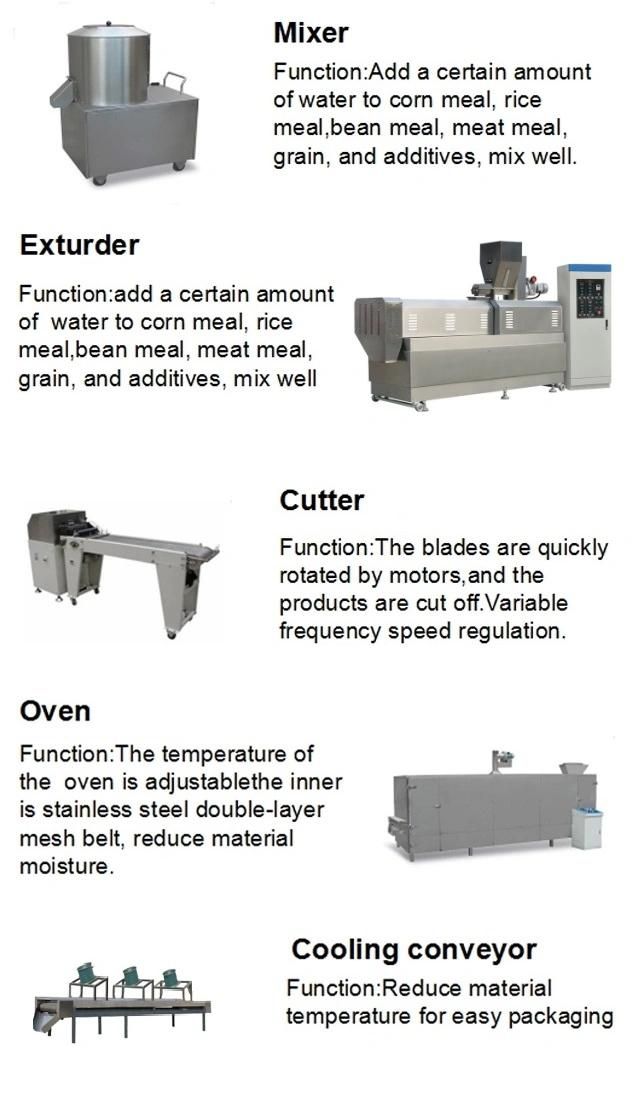

6. Flow chart

Mixing system---Extrusion system----Cutting system---Drying System--- Cooling System --Packing system

7. Voltage in China

Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries

8. Machines materials

All the machines are made by stainless steel

9. Technical Parameter

10. Our Services

1. Provide you the professional advice about the market, equipment, process, material, packing, etc.

2. Assist you to choose equipment, design process flow, and perfect workshop layout. If needed, we can supply service in your factory.

3. Make compensate plan to the material change according to your product, and perform the production at site.

4. Specially design and manufacture machine, practice test, and provide relevant training as customer required.

5. Provide reasonable packing and transportation plan, send technician to install and debug machine and train your workers.

6. One year guaranty time, preferentially supply spare parts.

7. Design and process similar type of spare parts of import equipment.

11. Packing and shipping

Every machine is packed with great care and tough material. It is packed with cling films first and then film bags. At last, it is packed with wooden case which is reinforced with the iron bar on the top and bottomWith this kind machine, all our laser machine can protect well during long trip by sea or by train.We can transport machine by boat or by training, according to your requirement.

12. Our Factory

13. Our Customers

14. FAQ

1. Are you a factory or trading company?

We are the manufacturer with more than10 years' experience. As only the machine made by ourselves, quality can be trusted, and most important thing is we can do better service after sales. We know how to fix the problem in each parts easily.

2. How long is the delivery time?

For standard machines, it would be 7-10 days; For non-standard machines and customized machines according to client's specific requirements, it would be 15-30 days.

3. How should I pay for my order? what is the procession of this purchase?

30% advance payment by T/T, the rest 70% before the shipment.

We will arrange the production after receiving your advanced payment. When the machine is ready, we will send you pictures.

After we got the rest payment, we will ship the machine to you.

4. How about your service after sales? Can your engineer speak fluent English?

We offer the service from you received the machine, including installation of the machine,

how to use machine? how to let machine work? usually we will teach you how to do by email or by Skype. Our engineer has many years of experience for CNC machine service. he can speak very good English, so he can solve the problem in short time.

5. How about the documents after shipment?

After shipment,well send all original documents to you by DHL, including Packing List, Commercial Invoice, B/L, and other certificates as required by client.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23