Twin Screw for Rubber and Plastic Extruders of Laboratory Scale

=== Base Info ===

=== Description ===

Basic Info.

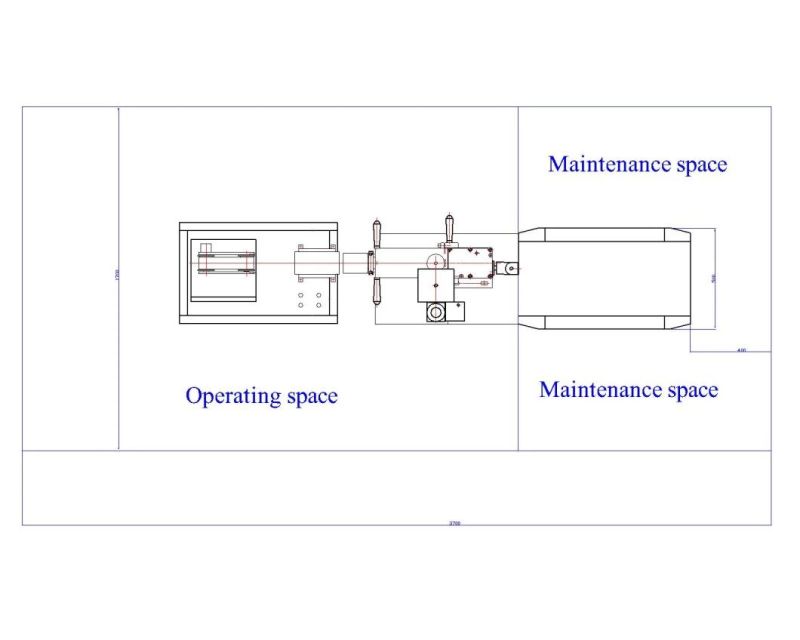

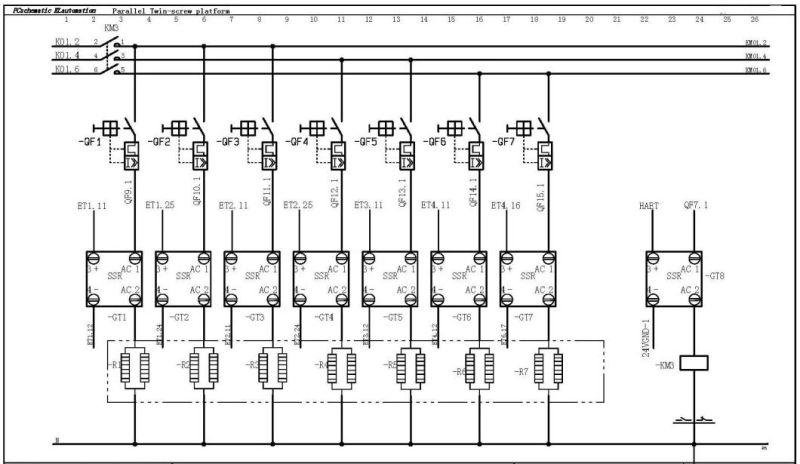

Assembly Structure Integral Type Extruder Screw Twin-Screw Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized Heating Electric Heating Screw Type Plastic Extrusion Screw Screw Diameter 25mm Screw L/D 28:1 Max. Speed of Screw 200 Rpm/Min Transport Package Plywood Trademark Hapro Origin China HS Code 9024900000 Production Capacity 100/YearProduct Description

Barrel contains materials and screw. The twin-screw is the heart of the extruder, divided into the charging section (solid conveying zone), compression section(melting zone) and the homogenization section (the melt conveying zone) three parts. Put the material into the hopper ,under the action of a rotating screw, material was pushed on to direction of the nose. Material endures strong shear, mixing and calendaring in the barrel, In this process, Meanwhile, the physical states of material the evolve from glass state to the high elastic state ,eventually become sticky flow pattern .Because of its rotation, the powder or particle shape plastic was pushed to the former, so as to achieve compaction, melting and mixing purpose of homogenization,

.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23