Pet Recycled Pellets Crystallizer in 20mins No Clumping No Yellow

Guangzhou Ouster Hydraulic Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Easy to be yellow Extremely uniform temperature distribution Final moisture About 30-70ppm About 200-500ppm

What we can do for you

√ Up to 60% less energy consumption than conventional drying system √Instant start-up and quicker shut down

√ No segregation of products with different bulk densities √Uniform crystallization

√ Independent temperature and drying time set √No pellets clumping & stick

√ Easy clean and change material √Carefully material treatment

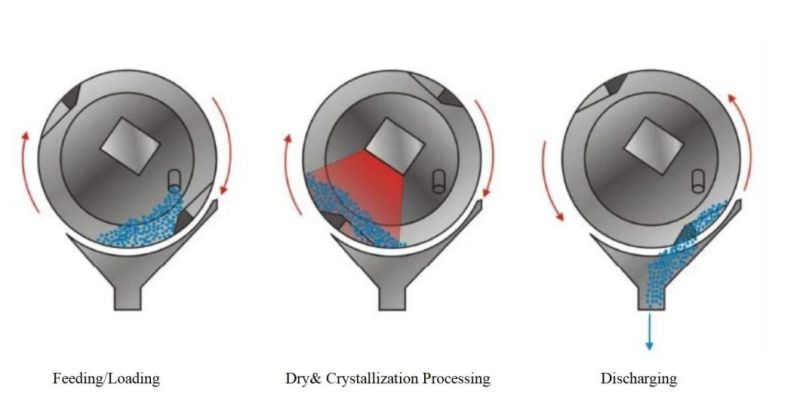

HOW TO WORK

>>At first step, the only target is to heat up the material to a preset temperature.

Adopt relatively slow speed of drum rotating, the Infrared lamps power of the dryer will be at a higher level, then the PET chips/flakes will have a fast heating till the temperature rises to the preset temperature.

>>Drying &Crystallization step

Once the material gets to the critical crystallization temperature, the speed of the drum will be increased to a much higher rotating speed to avoid the clumping of the material. At the same time, the infrared lamps power will be increased again to finish the crystallization and drying. Then the drum rotating speed will be slowed down again. Normally the drying and crystallization process will be finished after 15-20mins. (The exact time depends on the property of material)

>>After finishing the crystallization processing, the IR Drum will automatically discharge the material and refill the drum for the next cycle.

The automatic refilling as well as all relevant parameters for the different temperature ramps is fully integrated in the state-of-the-art Touch Screen control. Once parameters and temperature profiles are found for a specific material, theses settings can be saved as recipes in the control system.

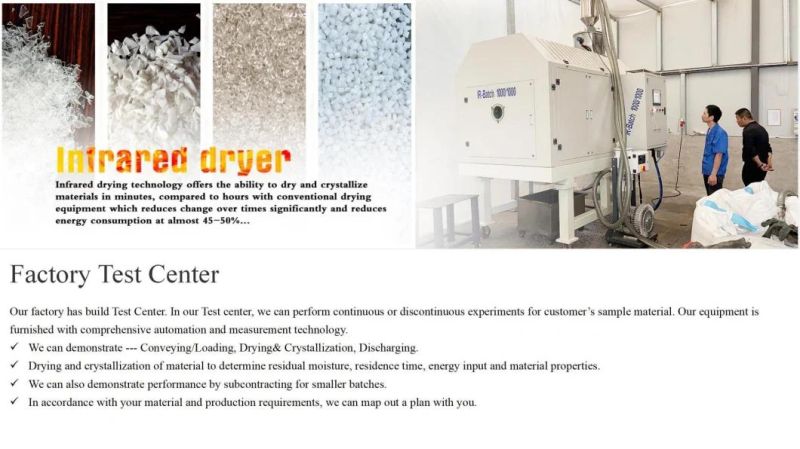

Material Free Testing

Experienced engineer will make the test. Your employees are cordially invited to participate in our joint trails. Thus you have both the possibility to contribute actively and the opportunity to actually see our products in operation.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23