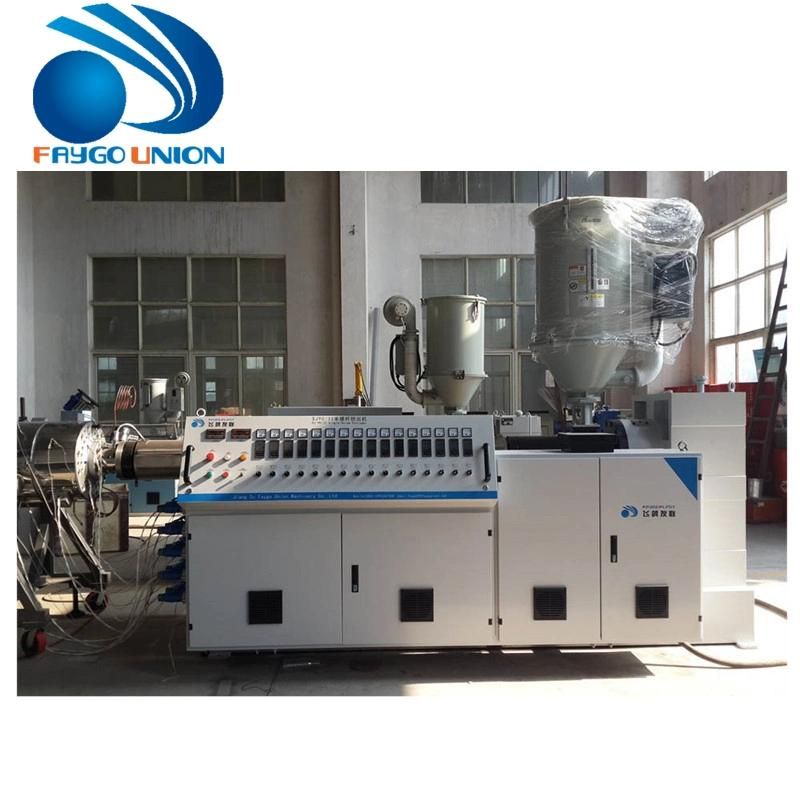

PVC PE Pellet Making Machine

Qingdao Kaier Xiang Diamond Tools Co., Ltd / 2022-07-04

=== Base Info ===

=== Description ===

a. Conical twin screw extruder:

Using the high efficient conical twin screws, specially designed for PVC power to ensure uniformed plasticization, high extrusion. Stable temperature controlling system can guarantee high quality pipe extrusion.

For CPVC material, the extruder adopt hollow screw, which has oil temperature control system for both screw.

b. Extrusion Mould:

Special mould for PVC and CPVC material, which ensure the pressure of extrusion.

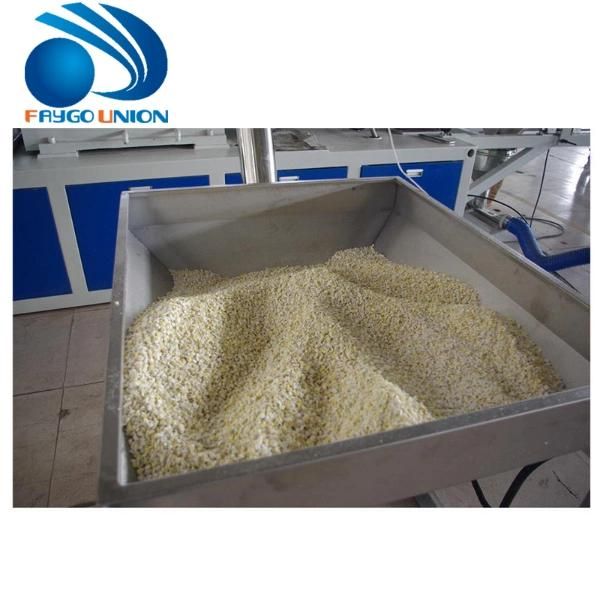

c. Pelletizer:

With hot die face cutter. Pelletizer adopt 4P motor which ensure the pelletizing speed. The pelletizing speed is controlled by inverter

d. air blowing system:

Two stage air blowing system. The granules will be cooled during the air tranportation.

e. vibrator:

To select the good granules.

Company Show:

Jiangsu Faygo Plast Machine Co., Ltd. is a professional company which devote ourselves to the development, research and production of plastic machines. Faygo has high quality products, accurate delivery time,quick response to after-sales service and very competitive prices.

Main products include: Plastic pipe production lines ,plastic board and profile production lines,plastic granulation production lines,plastic washing and recycling lines, production line supporting machines etc.

Shipping Show:

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23