Waste Plastic Washing Recycling Equipment Machine for Pet Bottles Flakes

Chenguang Machinery & Electric Equipment Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. BXA-500/1000/1500/2000/3000 Computerized Computerized Certification ISO9001:2008, CE Model No. Bxa Series Raw Material Pet Final Product Clean Pet Bottle Flake Name Pet Bottle Washing Line Technological Process Crushing-Washing-Drying Keywords Pet Washing Line Function Crushing Washing Drying Plastic Product Name Pet Bottle Hot Washing Plant Pet Recycling Line Type Pet Plastic Recycling Production Line Usage Plastic Washing Line Capacity 1000/2000/3000/5000kg/H Moisture Lower Than 1% Control PLC Touch Screen or Button with Light Motor Siemens, Wannan Label Remover 99% Transport Package Wood Film Specification 4200*2350*4870 Trademark Boxin Origin Jiangsu HS Code 8477800000 Production Capacity 1000kg/HProduct Description

Product Description of Plastic Recycling Machine

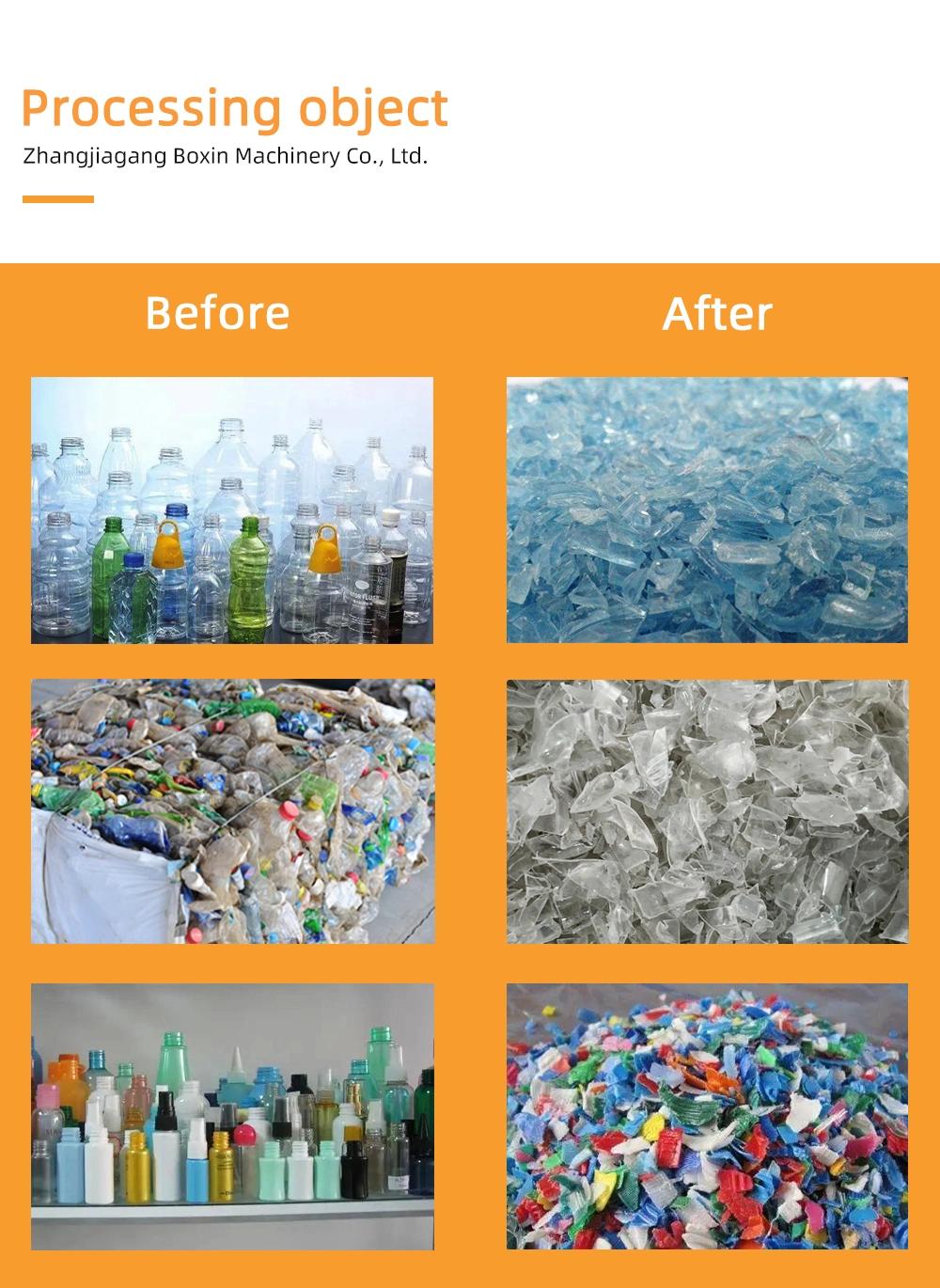

BOXIN brand PET bottles/bottle bales/flakes washing and recycling line mainly used to recycling waste PET bottle, PP PE HDPE hard bottles flakes, Blue Drums Chemical barrel, PVC and some other plastics. The whole line is fully automatic and it has characteristics of high efficiency, low noise and easy operation.the humidity of final output could be within 2%.It adopts hot water washing to get good quality. Various output capacities can be chosen: 500kg/h, 1000kg/h, 1500kg/h 2000kg/h.3000kg/h,5000kh/h.

The waste dirty material go through delabelling, crushing, washing, drying, and collecting process will turn to be clean flakes for reuse.This pet bottle washing machine can be displayed "L" or "U" shape according to clients' workshop.

We can also customize the washing line components according to client's material and product requirement.

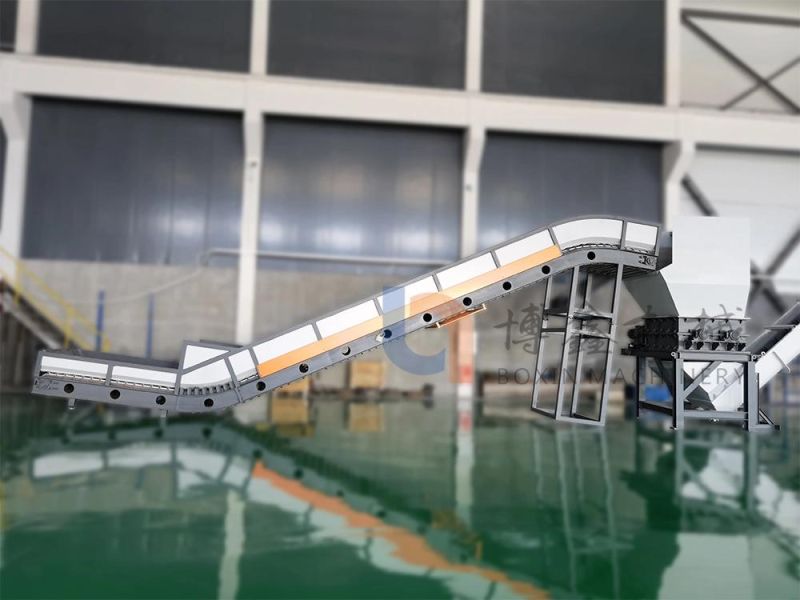

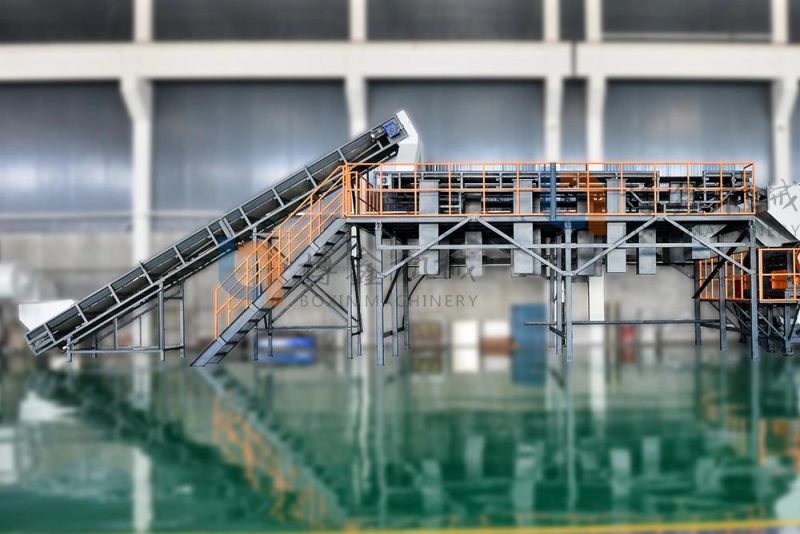

01 Conveying and De-baling System

The adjustable speed metal chain conveyor greatly improves the efficiency and more durable.

The De-baler machine adopts the special structure design of angle 2-axis unpacking and 2-axis breaking, which can fully dissolve the bottle bricks to ensure the subsequent conveying process, and at the same time reduce the energy consumption to the greatest extent.

02 Label Removing System

Mainly used to peel off the label paper on the PET surface;

Ensure the integrity of the bottle and neck, reduce the loss of high-quality bottle finish.

03 Manual Sorting System

Final classification and sorting of bottles before crushing;

The sorting system is a necessary way to ensure the quality of the foreign matter remaining in each unit of the previous section.

04 Crushing System

According to different output, choose different types of crusher;

The main shaft and box of the crusher are made of wear-resistant materials, which are safer and more durable.

05 high Speed Fiction Washing System

Add high-speed friction washing machine to remove impurities more effectively and achieve ideal cleaning effect.

06 Hot Washing System

Hot washing effectively removes residual glue, oil stains and some fine impurities on the surface of the bottle.

07 Dewatering Machine

The moisture content of the final material plays a vital role in the next process;

It can be equipped with corresponding centrifugal dehydration and hot air drying system according to your production requirements of moisture content .

BOXIN Machinery is a creative company, focusing on the technology R&D of plastic recycling, and providing the equipment and solutions for plastic washing, recycling and granulating. BOXIN Machinery plastic recycling technology mainly applied in the field of waste plastic regrinding, washing and regranuling. Thanks to the R&D ability and well-understanding industries experience, BOXIN Machinery can provide the customized plastics recycling solutions to customers. Typical productions Machinery can provide are: plastic washing line for PET bottles, PP PE film bags, HDPE Bottles , Plastic pelletizing recycling line for clean PP PE material , plastic shredder and crushers etc. Advantage of Machinery: Specialized R&D team involved in plastics recycling industries more than 15 years; Ability to provide the customized plastic recycling solutions; Complete sales system covering the pre-sale, sales and after sales; Professional engineers will perform debugging and technical guidance.

BOXIN Machinery is a creative company, focusing on the technology R&D of plastic recycling, and providing the equipment and solutions for plastic washing, recycling and granulating. BOXIN Machinery plastic recycling technology mainly applied in the field of waste plastic regrinding, washing and regranuling. Thanks to the R&D ability and well-understanding industries experience, BOXIN Machinery can provide the customized plastics recycling solutions to customers. Typical productions Machinery can provide are: plastic washing line for PET bottles, PP PE film bags, HDPE Bottles , Plastic pelletizing recycling line for clean PP PE material , plastic shredder and crushers etc. Advantage of Machinery: Specialized R&D team involved in plastics recycling industries more than 15 years; Ability to provide the customized plastic recycling solutions; Complete sales system covering the pre-sale, sales and after sales; Professional engineers will perform debugging and technical guidance.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23