High Quality Custom Design Precooked Corn Mill

Cangnan Laijiu IMP & EXP Co., Ltd. / 2022-07-05

- Type:Flour Mill

- Application:Flour, All, Wheat

- Voltage:380V,440V

- Appearance:Vertical

- Press Materials:Corn

- Press Series:Second

=== Base Info ===

- Model NO.:HDF10t,d HDF20t,d HDF30t,d HDF50t,d

- Condition:New

- Customized:Customized

- Name:Venezuela Peru Pre Cooked Corn Flour Milling Mach

- Installation:Two Month

- Capacity:1tph 2tph 5tph 10tph

- Color:Customized

- Spare Parts:Two Year

- Material:Corn

- Final Products:Precooked Corn Flour

- Installed Line:Kenya Uganda Zambia Burundi Brazil Argentina Peru

- Branch Office:Lusaka Zambia

- Function:Cleaning Milling Packing

- Transport Package:Plastic Film, Transported in Container

- Specification:GB1355-88, ISO9001: 2000

- Trademark:Hongdefa

- Origin:Hebei, China

- HS Code:8437800000

- Production Capacity:20sets,Month

=== Description ===

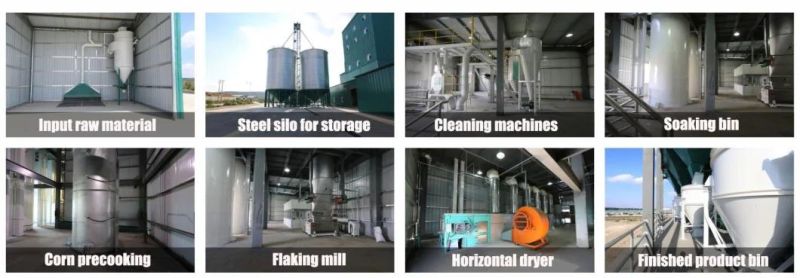

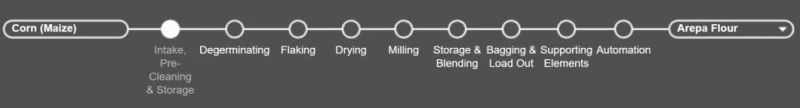

FLOW CHART--->>>

The series of precooked corn/maize flour milling machine are designed and installed together with the steel structure support. The main support structure is made of three levels: the roller mills are located on the ground floor, the sifters are installed on the first floor, the cyclones and pneumatic pipes are on the second floor.

The materials from the roller mills are lifted by pneumatic transferring system. Enclosed pipes are used for ventilation and de-dusting. Workshop height is relatively low to reduce customers' investment. The milling technology can be adjusted to satisfy customers' different requirements. Optional PLC control system can realize central control with high degree of automation and make operation easier and flexible. Enclosed ventilation can avoid dust spill to keep high sanitary working condition. The whole mill can be compactly installed in a warehouse and designs can be customized as per different requirements.

In the cleaning section, we adopt drying type cleaning technology. It normally includes 1 time sifting, 1 time scouring, 1 time de-stoning, 1 times aspiration, 2 times dampening, 2 times magnetic separation and so on. In the cleaning section, there are several aspiration systems which can reduce the dust spray-out from the machine and keep a good working environment.This is a complicated thorough flow sheet which can remove most of the coarse offal, middle size offal and fine offal in the wheat. The cleaning section is not only suitable for wheat imported with lower moisture and but also suitable dirty wheat from local customers.

In the milling section, we use chamber cooker, flake mill and hammer mill. Inside chamber cooker, saturated steam keeps cooking corn grits bit by bit for nearly 40 minutes, and meanwhile, the moisture of grits increases from 17% to nearly 20%. During this part of process, the grit structural protein goes denatured and soft; the hydrogen bonds that maintain the structure of corn starch fall apart and the starch begins to absorb water. After steam cooking, the softened grits are milled into flakes through flake mill, and the thickness is about 1.0 mm. Flakes have larger contact area than grits do, so it makes easier for drying and cooling process. The dryer & cooler has a heated air system and a cool air system, which can dry and cool the flakes; meanwhile the moisture of maize flakes decrease to nearly 12%, which is all right for storage. Then the hammer mill will mill the corn flake into final flour;

Packaging--->>>: suitable for sea shiping

*Our clients --->>>

Successful projects in more than 40 countries: South Africa, Malawi, Kenya, Zimbabwe, Zambia, Mozambique, Rwanda, Ethiopia, Albania, Egypt, Angola, Afghanistan, Venezuela, Argentina, Brazil,

*ABOUT US --->>>

Shijiazhuang Hongdefa Machinery Co., Ltd is located in Wumashan industarial area, Zanhuang County, Shijiazhuang City, 4hours driving From Beijing and 5 hours driving from Tianjin port. Hongdefa has more than 120 workers, a manufacturing factory 50000 square meters, and 5000 square meters of production workshop, 6000 square meters warehouses, 1000 square meters of office space.

we have the advanced product machinery in our factory. --->>>

Experienced technician and sales team

All our machinery are high quality and have passed the certification of ISO, CE, BV, SGS and COC. and our machines can get any Certificate depend on client's needing.

Lifelong oversea services

Since 2007, we opened the branch office in Lusaka of Zambia,where has a big storage room, easy access to some machines and spare parts for Zambia customers and around countries clients, like Zimbabwe, Tanzania, RD Congo, Angola, Malawi,Namibia , Botswana and so on.

Contact informaiton:

Now send your inquiry to me or talk with me online to ask more for the maize mill machine. You also can find me through the below way:

MS. Helen

Add: No.388Jianhua North Street, Shijiazhuang, Hebei, China.

super white corn flour mill pre cooked corn flour mill

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23