Hydraulic Waste Paper Pressing and Baling Machine Carton Compress Baler Packing Machine

DONGGUANG XINGLONG PACKAGING MACHINERY CO., LTD. / 2022-06-27

- Model:Y106m

- Voltage:380V

- Certification:Ce, ISO9001:2008

- Warranty:1 Year

- Hydraulic Cylinder:125journey 1m

- Motor:Y160m-4-11kw

=== Base Info ===

- Model NO.:Y160M

- Distributor:Pressure 31.5 Flow 75

- Oil Pump:Output50, Pressure 25MP Left Rotate

- Baler Size:700*1100mm

- Oil Pipe:Seamless Steel Tube

- Dimension:1.9×1×2.9m

- Weight:About 1.3ton

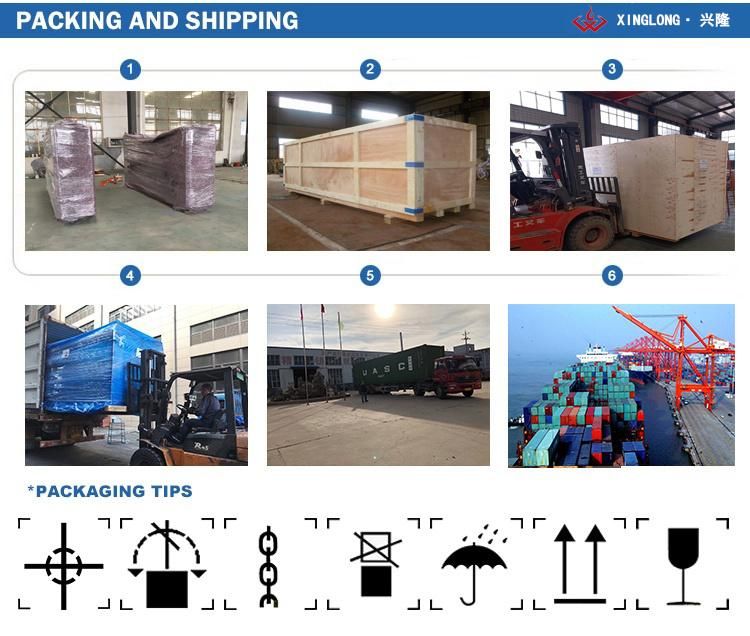

- Transport Package:Wodden Case, Container

- Specification:other

- Trademark:XINGLONG

- Origin:Hebei, China

- HS Code:4401210010

- Production Capacity:2set,Month

=== Description ===

Basic Info.

Model NO. Y160M Distributor Pressure 31.5 Flow 75 Oil Pump Output50, Pressure 25MP Left Rotate Baler Size 700*1100mm Oil Pipe Seamless Steel Tube Dimension 1.9×1×2.9m Weight About 1.3ton Transport Package Wodden Case, Container Specification other Trademark XINGLONG Origin Hebei, China HS Code 4401210010 Production Capacity 2set/MonthProduct Description

Hydeaulic waste paper pressing and baling machine

Function and uses:

The vertical hydraulic baler is applied to loose material compression and packing, and uses hydraulic drive to compress the compressible resources to reduce the volume and form a whole. The block density is high and the outer dimensions are uniform. It is packed with wire or packing tape. Widely used in the compression packaging of waste paper, plastic bottles, plastic film, clothing, woven bags, cotton yarn, waste cotton, cloth, waste cloth, sacks, hair balls, metal processing thin materials, etc., effectively reducing the placement The land occupation has improved logistics efficiency, reduced transportation losses, drastically reduced freight rates, and beautified the office and production environment. At the same time, it reduces labor intensity and improves work efficiency. It is an ideal choice for various manufacturing plants, material recycling stations and renewable resource recycling companies.

Technical parameter:

| Item | Model | Qty |

| Hydraulic cylinder | 125journey 1m | 2 |

| Motor | Y160M-4-11kw,380v | 1 |

| Distributor | Pressure 31.5 flow 75 | 1 |

| Oil pump | Output50, pressure 25mp left rotate | 1 |

| Baler size | 700×1100(mm) | Baler Weight 200-300kg |

| Oil pipe | seamless steel tube | |

| Dimension | 1.9×1×2.9m | |

| Weight | about 1.3ton |

FAQ:

1. Q: What is your delivery term?

A: FOB,CIF,CFR usually.

2.Q: What is your payment?

A: T/T.30% deposit, 70% balance before delivery.

L/C. 100% at sight.

T/T and L/C, 30% TT deposit, 70% L/C.

3.Q: What is your delivery time?

A: Die cutting machine, 30-40 days usually. If urgent, 15 days only.

Paper cutting machine, 20-30 days usually. If urgent, 15 days only.

4.Q: What is your warranty and other terms?

A: One year warranty. Spare parts are free for customer in 1 year, but customer have to pay delivery. We can send our engineer to customer factory for 7 days free installing and trainning, customer have to pay tickets, visa, meals and hotel. If need more training, $100.00 per day to our engineer.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23