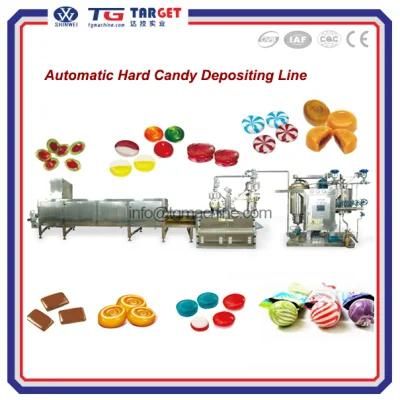

Automatic Hard Candy Depositing Line Candy Machine with High Quality

Hebei Hightop Metal Mesh Co., Ltd. / 2022-07-05

- Certification:CE, ISO9001

- Power Source:Electric

- Process:PLC

- Automatic Grade:Automatic

- Application:Candy

- Customized:Customized

=== Base Info ===

- Model NO.:GD150

- Forming:Deposite

- Transport Package:Wooden Case

- Specification:CE

- Trademark:TGMachine

- Origin:Shanghai

- HS Code:84382000

- Production Capacity:50sets,Year

=== Description ===

Basic Info.

Model NO. GD150 Forming Deposite Transport Package Wooden Case Specification CE Trademark TGMachine Origin Shanghai HS Code 84382000 Production Capacity 50sets/YearProduct Description

Automatic Hard Candy Depositing Product Line PLC programmed

GD150/300/450/600 hard candy depositing line is a compact unit which can continuously produce various kinds of hard candies under a strict sanitary condition. It is also an ideal equipment which can produce out good quality products with the saving of both the manpower and the space occupied.

Model | GD150 | GD300 | GD450 | GD600 |

Output(kg/h) | 150 | 300 | 450 | 600 |

Max candy weight | 6g | 6g | 6g | 6g |

speed | 55~65 n/min | 55~65 n/min | 55~65 n/min | 55~65 n/min |

Steam consumption Steam pressure | 250kg/h, 0.5~0.8MPa | 300kg/h, 0.5~0.8MPa | 400kg/h, 0.5~0.8MPa | 500kg/h, 0.5~0.8MPa |

Compressed air consumption Compressed air pressure | 0.2m3/min, 0.4~0.6MPa | 0.2m3/min, 0.4~0.6MPa | 0.25m3/min, 0.4~0.6MPa | 0.25m3/min, 0.4~0.6MPa |

Electric power needed | 18kW/380V | 27kW/380V | 34kW/380V | 42kW/380V |

Total length(m) | 15 | 17 | 17 | 20 |

Gross weight | 3500kg | 4000 kg | 4500 kg | 5000 kg |

The strong point of the line is as following:

1. PLC /computer process control available;

2.An LED touch panel for easy operating;

3.The standard production capacity from 150 kgs/h to 450kgs/h;

4.The main parts is made of hygienic stainless steel;

5.Optional (mass) flowing controlled by Frequency inverters ;

6.In-line injection, dosing and pre-mixing techniques for the proportional addition of liquid(milk); Dosing pumps for the automatic injection of colors, flavors and acids;

7.One set of extra chocolate paste injection system for making chocolate-central candies; "two/three-color striped depositing","two or three color double layers depositing", "central filling", "clear" hard candies and etc. can be made.

8.Moulds can be made according to the candies samples provided by the customer

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23