Industrial High Precision Metal Laser Cleaning Machine

Zhangpu Guangguang Plastic Products Co., Ltd. / 2022-06-23

- Model:PE-X50

- Cooling Method:Air Cooling

- Length of Light:3 Meters (Optional 5 Meters)

- Power Supply:220V-50,60Hz

- Laser Grade:4

- Transport Package:Compound Wooden Cases

=== Base Info ===

- Model NO.:PE-X100

- Specification:CE, ISO

- Trademark:Perfect Laser

- Origin:Wuhan, China

- HS Code:84561000

- Production Capacity:5000PC Per Year

=== Description ===

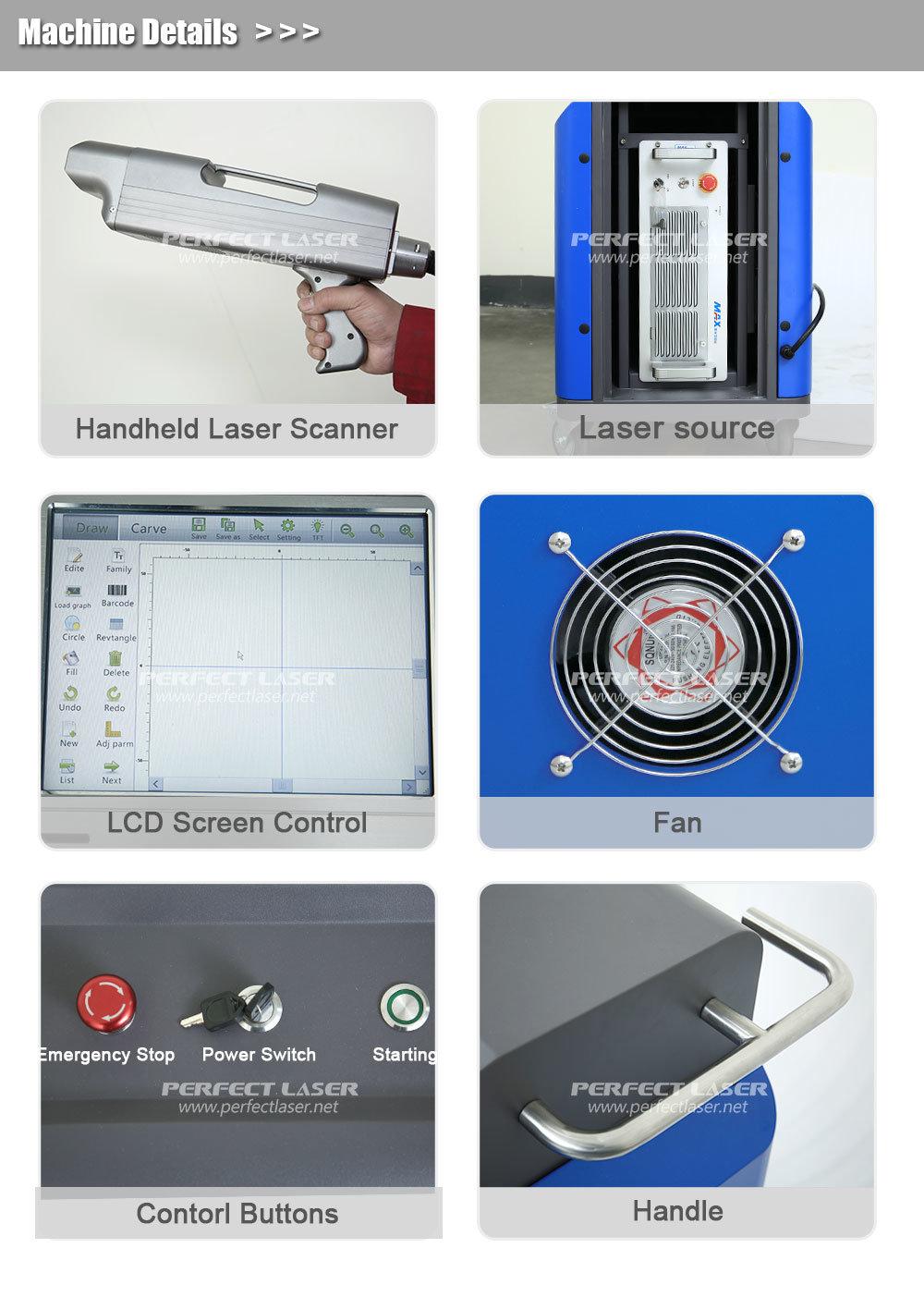

Equipment comes with a variety of patterns, free choice processing (linear, round type)Detailed Images

Machine Advantage

1.Non contact cleaning of the portable laser rust remove machine does not damage the base of parts;

2.Accurate cleaning, accurate location, precise size, optional cleaning;

3.No chemical cleaning liquid, no supplies, safety and environmental protection;

4.The operation of the handheld laser rust remover is simple, the power supply can be achieved, and the automatic cleaning can be carried by hand or with the manipulator;

5.Using light guide fiber, the high power laser beam is introduced into the reactor, and the radioactive dust of the laser metal cleaning machine is removed directly. The cleaning material is easy to clean;

6.The laser cleaning system of the handheld laser rust remover is stable and requires little maintenance.

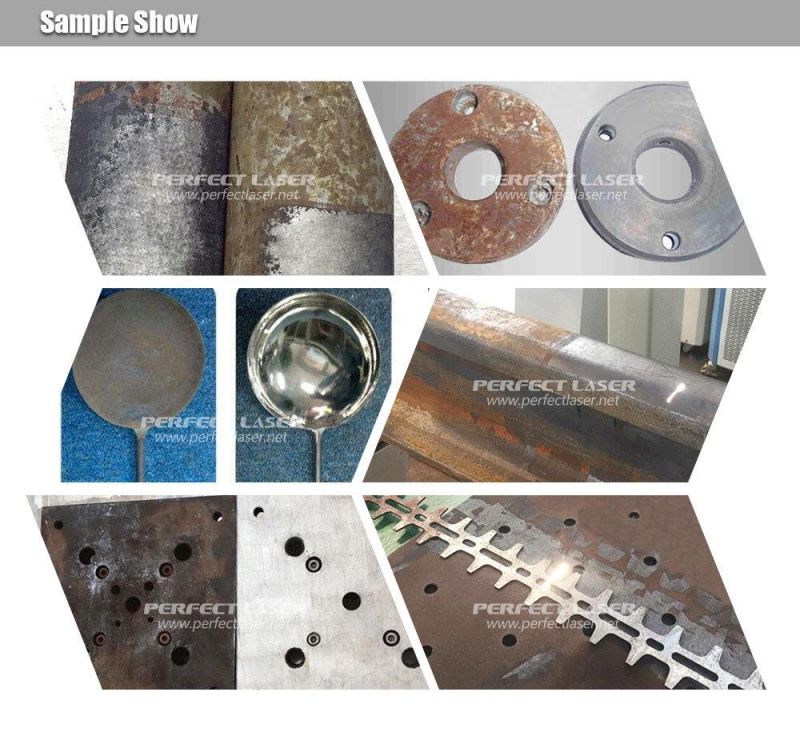

Application

The industrial laser cleaning machine is widely used in the shipping industry, auto parts, rubber mold, high-end machine tools, tire mold, track, environmental protection industry and other fields. Such as:

Cleaning of aviation components:

In the process of cooperation with the aviation industry, the laser metal cleaning machine has been proved that the laser can clean nickel, stainless steel, aluminum and high strength steel molds or parts efficiently, without damage to the substrate.

Cleaning of weapons and equipment:

Laser cleaning technology is widely used in weapon maintenance. The laser cleaning system can remove rust and pollutants efficiently and quickly, and the cleaning parts can be chosen to realize the automation of cleaning. Portable laser rust remove is not only more clean than chemical cleaning, but almost no damage to the surface of the object. By setting different parameters, a compact oxide protective film or metal melting layer can be formed on the surface of the metal object to improve the surface strength and corrosion resistance. Laser cleaning waste basically does not constitute pollution to the environment, and can also be operated remotely, effectively reducing the health damage to the operators.

The removal of old paint from an airplane:

Laser metal cleaning machine have long been used in the aviation industry. The surface of the aircraft must be repainted after a certain period of time, but the old paint must be removed before painting. The traditional mechanical cleaning method is liable to cause damage to the metal surface of the aircraft and cause hidden trouble in safe flight. If the laser cleaning system is adopted, the paint layer on the surface can be completely removed without damaging the metal surface.

Precise ester cleaning in precision machinery industry:

The precision machinery industry is often required to remove esters and mineral oils that are used for lubrication and corrosion resistance on parts, usually chemically, while chemical cleaning often remains. The removal of ester and mineral oil by laser de ester can completely remove the surface of the parts. The pollutant removal is made by shock wave, and the oxide thin layer of the parts is explosively gasified to form shock wave, which results in the removal of dirt instead of mechanical interaction. The material is thoroughly removed and used for the cleaning of mechanical parts in aerospace industry. Oil removal in mechanical parts processing can also be done by laser cleaning.

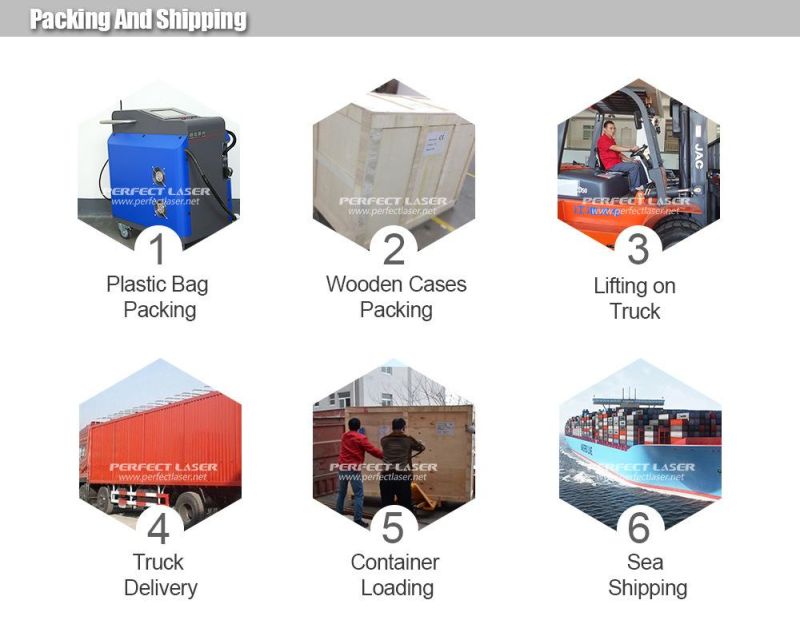

Packing & Delivery

Our Service

* 24 Months Guarantee

* 5-7 Days Lead Time

* VCD Training , Easy Installation

* 18 Hours Response

* TT/Western Union / Paypal / Alibaba Trade Assurance Payment

* Sea Shipping/Air Shipping/Door to Door Express Shipping

1. 3 year guarantee for laser source.

2. Full technical support by e-mail, call and video

3. Lifelong maintenance and spare parts supply.

4. Free design of fixtures as customers required.

5. Free training installation and operation for the staffs.

Emma/ Sales Department < Technology Creates Perfect! >

Add: HengRuichuangzhi Technology Park, No.13 YangQiaohu Road, Jiangxia District, Optical Village, Wuhan, Hubei, China.

Tel: 0086-27-86791986 MP: 86-136 5988 3308

Fax: 0086-27-86775865

Website: perfectlaserco.en.made-in-china.com

FAQ

Q: What's the package?

A: We have 3 layers package. For the outside, we adopt wood craft case. In the middle, the machine is covered by foam, to protect the machine from shaking. For the inside layer, the machine is covered by thickening plastic bag for waterproof.

Q: Will the package damaged during transportation?

A: Our package is considerate all the damage factors and make it to be safe, and our shipping agent have full experienced in safe transportation. We have exported to 180 countries worldwide. So please don't worry, you will receive the parcel in good condition.

Q: How to install and run the machine?

A: Our technician have installed the machine before shipping. For some small parts installation, we will send detail training video, user's manual along with the machine. 95% customers can learn by themselves.

Q: How can I do if the machine goes wrong?

A: If confronted with such problems, please contact us asap and do not try fix the machine by yourself or someone else. We will response within 24 hours as quick as we can to solve it for you.

Contact:

Perfect Laser Co., Ltd. (China)

Mob: +8613886034275

Add: HengRuichuangzhi Technology Park, No.13 YangQiaohu Road, Jiangxia District, Optical Village, Wuhan, Hubei, China(430200).

Tel: 0086-27-86791986 Fax: 0086-27-86775865

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23