High Quality Drip Irrigation Pipe Machine

Zhejiang Longyou Huiyang Foreign Trade Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

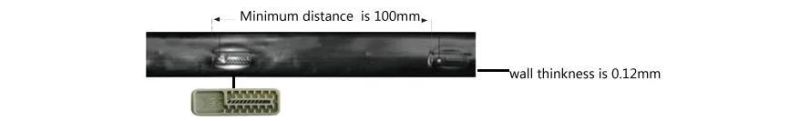

Model NO. SJ60 Condition New Raw Material PE Pipe Diameter 12mm-16mm-20mm Pipe Thickness 0.12-0.9mm Max Speed 320m/Min Distance of Dripper 100mm-1500mm Dripper Screening Speed 3000 Pieces/Min Extruder Sj-60/38 Main Motor Power 52.8kw Vacuum Calibrating Tank 4m Cooling Water Tank 4m*2 Full Automatic Punching 3 Sets Servo Punching Device Punching Speed 3000 Times/Min Driving Mode Servo Motor Contactor Siemens PLC Siemens Transport Package Wooden Box Suitable for Sea Shipment and Export Specification 34-36m*5m*3m Trademark ZEANON Origin Qingdao China Production Capacity 100sets/YearProduct Description

China Made Flat Drip Irrigation Pipe LineTechnical parameter:

| Model | Pipe diameter | Pipe thickness | Highest speed | Distance of dripper |

| XDC-DGG 300B | Φ12-16-20-22-25mm | 0.12-0.6mm 0.2-1.0mm (optional) | 320m/min | 100,150,200,300,400,500-1500mm |

| Space 100mm | Line speed 300m/min |

| Space 200mm | Line speed 320m/min |

| Space 300mm | Line speed 320m/min |

Product description:

Drip irrigation pipe machine is a high-speed production equipment of thin-wall drip irrigation pipe independently developed by XINDACHENG. "ZEANON" is an independent brand developed by Qingdao Xindacheng together with European well-known drip line manufacturer. Zeanon products cover all aspects of the drip irrigation field, including water-saving irrigation technology & machinery, engineering design, drip products and drip irrigation pipe machine.

1. Dripper feeder device: double sets. Dripper feeding speed: 3000pcs/min.

2. Have dripper buffer device, make sure non-stop machinery even if happen bad quality dripper block on feeder.

3. Extruder: Servo direct drive, save power.

4. Extruder die head & calibrating: Germany technology, thickness adjustable.

5. Configuration: One-button automatic pipe-holding dripper insert device.

6. Irrigation pipe accumulator: equipped with the most advanced European parallel accumulator device.

7. Automatic drilling device: 3 units. speed: 3000times/min.

8. Configure online automatic imaging analysis and monitoring punching system: monitor the punching status, realize the error automatic alarm function, and ensure the product punching rate.

9. Line speed: 320m/min, it is the fastest production efficiency in the world.

* dripper space 100mm, speed: 300m/min.

* dripper space 200mm, speed: 320m/min.

* dripper space 300mm, speed: 320m/min.

Feature 1:

Zeanon irrigation pipe weights less than 7g/m,Reduce 30% material which will largely save cost.

Feature 2:

• Configured with advanced dripper buffer and insertion unit (Europe technology)

• Insert 3000 pieces of dripper per minute.

Feature 3:

• Advanced dripper,weights only 0.1g/pcs(China exclusive agent).

• Qingdao Xindacheng import from Europe, China exclusive agent.

• High efficient inner irrigation pipe dripper adopted high efficient injection mold technology.

• All produced in Europe, to make sure of the quality.

Feature 4:

• Double Auto Punching Unit(3 unit)--leading technology in the world;

• Punching device fixed with online monitor & picture indentify system, store the punching system;

• Auto alarm for wrong punching, it is controlled by PLC system;

• Tracking and adjust the punching system in time.

Feature 5:

• Auto winder + Accumulator device

• This is an important part of the drip irrigation pipe machine.

• It is drived by servo motor.

• Automatically wind the dripper irrigation pipe.

• Controlled by PLC system.

Company informations:

Qingdao Xindacheng Plastic Machinery Co., Ltd., a high-tech join-stock enterprise, integrates scientific research development, technology transfer, production and sale. In addition, it is the unit for accomplishing key promotion projects of science and technology result in construction department.

The company mainly engages in research, development, design, manufacture and sales service of new type plastic machinery, is able to provide "Turn-key project" of complete set of production line for many plastic product. It owns powerful technology strength, gathers professional scientific and research talents in top grade macromolecule material national wide, polymer processing, industrial automatization and marketing. Besides, it keeps closely contact with chemical design research institute and universities, so it is familiar with market trend and is able to transfer the latest science and technology achievements in the fastest speed so that to provide whole set of technology such as the most competitive equipment, technology and relevant technology consultation service.

Oriented by human, Xindacheng considers that the innovation and credit is the most important. It will offer first-class product and considerate service to help you in accomplishing great business and cooperate with together to create new era in plastic machinery industry.

Xindacheng always considers that customers' interest is the first important. Over decades, Xindacheng's product spreads all over the country and exported to more than 40 countries and regions such as, U.S. Italy, Canada, South Korea, Japan, Russia, Ukraine, Czech, Turkey, Mexico, Iran, Saudi Arabia, Egypt, Indonesia, Singapore, Taiwan, HK, Malaysia, and wins customers' reputations.

Company board chairman and staff warmly welcome friends from all circles to visit us.

Why choose XINDACHENG?

• We supply all the technical support, such as engineers, drawings, and instruction manual.

• We send one or more than one engineers to client for installing and adjust all the machinery.

• Buyer also can sent workers to our workshop for learning how to conduct Plastic extruder.

• Supply formula guide service and staple raw material purchase.

• We could supply the Feasibility Analysis Report for the project.

• We could supply turnkey project to you.

• We have good reputation from our customers both at home and abroad.

Certificate:

FAQ:

Q: Where is your factory? How can I get there?

Way 1: you take the train to Gaomi station (Weifang City), we will pick you up. It's only 30 minutes from our factory to Gaomi station.

Mode 2: take a plane to Liuting International Airport (Qingdao), we will meet you, 40 minutes from the factory to the airport.

Q: how is your factory doing in quality control?

A: the electrical part has cooperated with famous foreign brands such as Yaskawa, Siemens, NSK, Delta, Panasonic, etc. the other part comes from domestic high-quality manufacturers and will be tested before delivery.

Q: is there any overseas service?

A: Yes, we have an experienced service team. Each team member has gone abroad many times and has rich experience in machine installation. But the buyer needs to provide air tickets, food, hotel fees, etc.

Q: how does your company provide after-sales service?

A: all machines purchased from our company are provided with a one-year warranty period (except for human errors). We will supply some spare parts for replacement at the time of delivery. In case of damage to machine parts in the warehouse, we will send you free parts by express as soon as possible.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23