PP PE Hollow Sheet Plastic Extrusion Line (SJ-120/33) with CE Certification

CHINA GTL TOOLS LIMITED / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. SJ-120/33 Assembly Structure Integral Type Extruder Screw Single-Screw Engagement System Full Intermeshing Screw Channel Structure Deep Screw Exhaust Exhaust Automation Automatic Computerized Computerized Width of PP Hollow Sheet 1220mm Valid Width of Mould 1400mm Screw Material 38crmoala Nitriding Plastic Machine Type PP, PE Hollow Sheet Plastic Extrusion Line Hollow Sheet Plastic Machine Quality CE Standard Test Extruder Single Screw Extruder for Hollow Sheet Low Voltage Appliances Siemens Export Range Global Thickness of Hollow Sheet 2-10mm Project Hollow Sheet Plastic Machine Turn Key Project Transport Package Plastic Machine Export Standard Packing Specification SJ-90/33, SJ-120/33, etc Trademark WEIER Origin Qingdao City, Shandong Province, China HS Code 84772090 Production Capacity 20 Sets Per QuarterProduct Description

PP PE hollow grid sheet plastic extrusion line

1. Introduction:

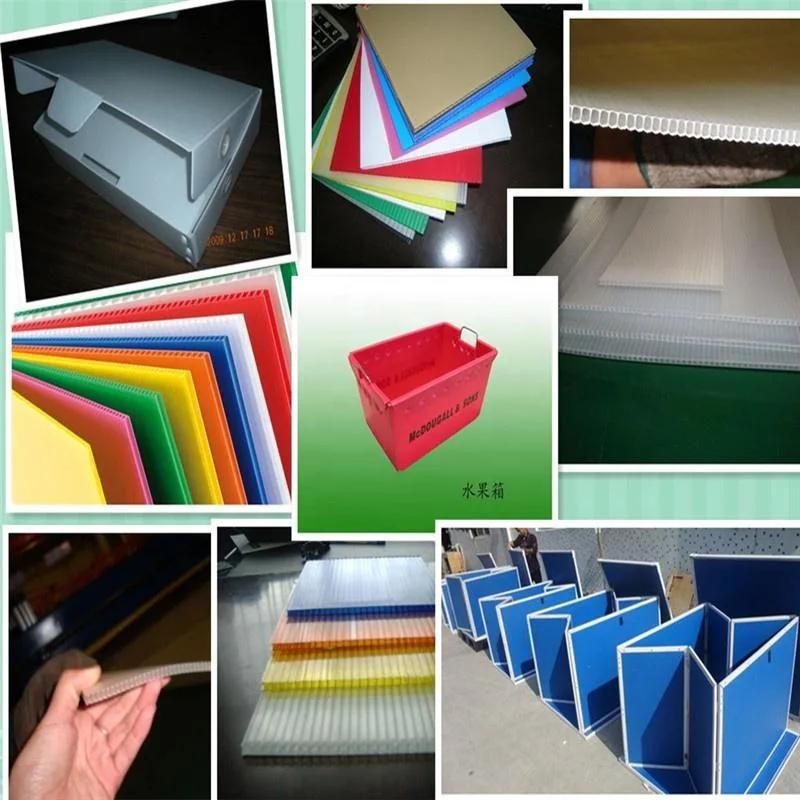

The PP, PE hollow grid sheet having the strong point of smooth and clean surface, good outlook and pressure resistance.

It can be widely used in construction, packing and adornment industries. The PP, PE hollow grid sheet plastic machine extrusion line can produce PE/PP hollow gird board/sheet as well as agricultural and construction transparency warm keeping PP PE hollow board/sheet through changing the molding die.

2. Composition of the PP, PE hollow sheet plastic machine extrusion line:

| NO | NAME | QUANTITY |

| 1 | Vertical color mixer | ONE SET |

| 2 | Single screw extruder SJ-90/33 | ONE SET |

| 3 | Hydraulic screen changer | ONE SET |

| 4 | Mould for hollow grid sheet | ONE SET |

| 5 | Vacuum sizing machine | ONE SET |

| 6 | Six pair rollers first haul off machine | ONE SET |

| 7 | Infrared heat treatment device | ONE SET |

| 8 | Two pair rollers second haul off machine | ONE SET |

| 9 | Automatic cutting machine | ONE SET |

| 10 | Conveyor | ONE SET |

| 11 | Electrical control system | ONE SET |

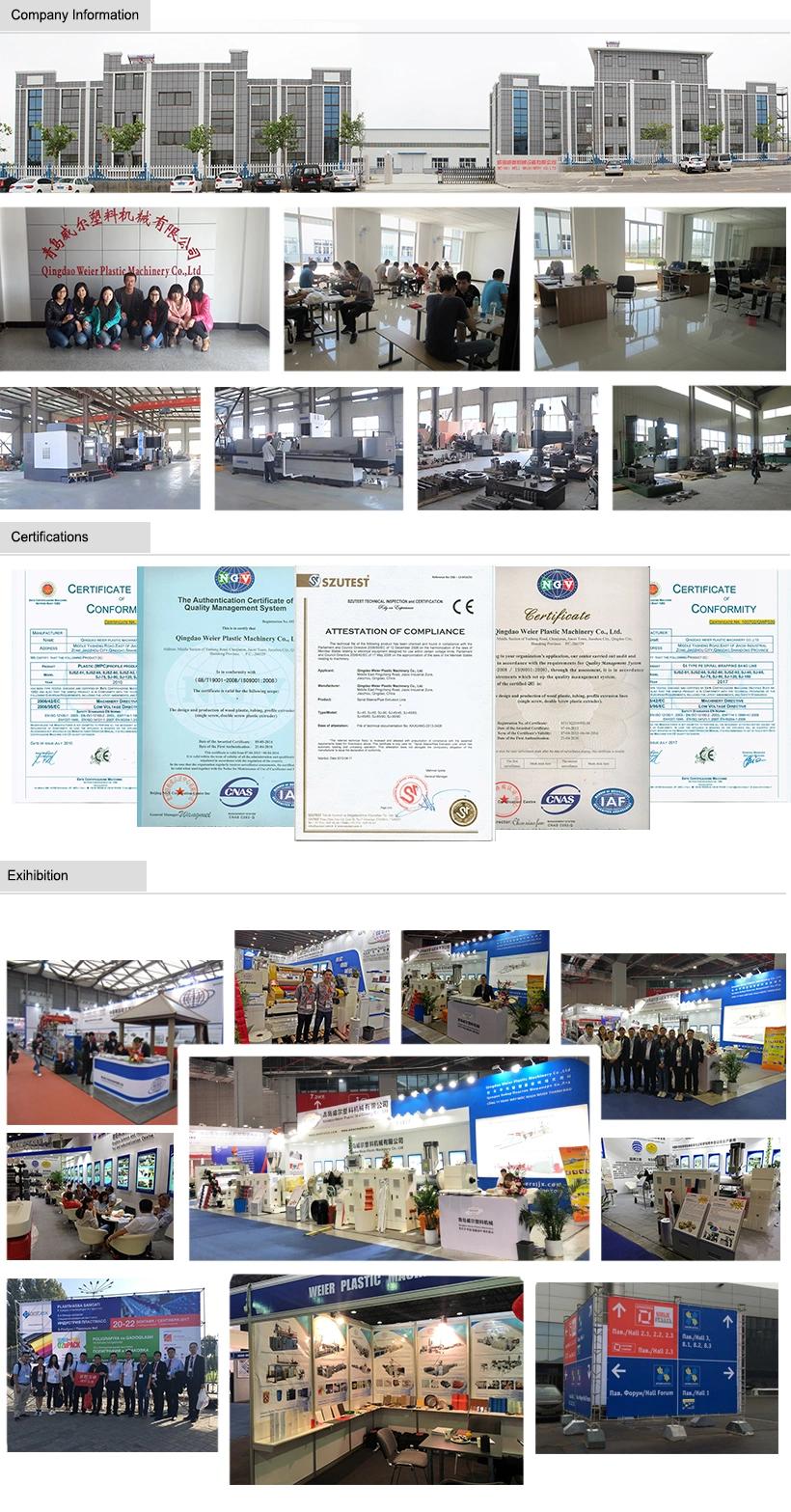

3. WHY CHOOSE WEIER?

(1) we have experiences in this field since 1980s

(2) we have our production bases in China, which shows our machine's production power

(3) we have strond technical teams and cooperate with China scientific institution to develop, improve and test our machine

(4) we have perfect service system: Our boss is devoting himself to after-sale service

We will provide the Feasibility Analysis Report for the plastic machine project.

We will provide the model design for the plastic machine plant and electric power accounting for the facilities.

We will provide the model selection and technical parameter for our plastic machine.

We will provide plastic formular according to the product requirements.

We will provide technique training for operator.

We will provide solution for the practical problem during the production.

We will install and test the plastic machineand teach customer's workers how to operate in customers' factory.

We will provide turn-key project to customers.

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23