Potato Crisps Production Line/Frozen French Fries Processing Plant

Fuzhou Qianxi Trading Co., Ltd. / 2022-07-05

- Certification:CE, ISO9001

- Power Source:Electric

- Process:Frozen and Chilled

- Automatic Grade:Automatic

- Application:Chips, Fries

- Customized:Customized

=== Base Info ===

- Model NO.:TUNE-ST100

- Transport Package:Container

- Trademark:TUNE

- Origin:China

- Production Capacity:100-2000kg,H

=== Description ===

Basic Info.

Model NO. TUNE-ST100 Transport Package Container Trademark TUNE Origin China Production Capacity 100-2000kg/HProduct Description

Product DescriptionFrozen french fries production line machine

Potato chips production line machine

This Full automatic frozen french fries production line machine and fully automatic potato chips production line is mainly composed of potato washing & peeling machine, cutting machine, blanching machine, dehydrator, frying machine, deoiling machine, flavour machine and packing machine. Easy operation, high output and good production effect. Potato chips and French fries seem very smooth and uniform. Besides,the thickness could be adjusted freely. Apart from making potato chips, French fries, you could also make Frozen French fries(equip with IQF quickly freezer).The automatic potato french fries production line combines the procedures of make fresh natural potato into fries together.

Input 1000kg potatoes per hour, come out 600-700kg frozen fries.

Potato RequirementsOval in shape Dry material content≥20% Sugar content≤0.4%;

Potato RequirementsOval in shape Dry material content≥20% Sugar content≤0.4%; Length ≥68mm Color outside is yellow Color inside is white

Less and small bud hole

Equipment Description

1. Hoister with water sprayIt is used to preclean potato,soften the potato skin, then hoist potatoes into washing and peeling machine.

2. Washing and peeling machine

This machine is used to peeling potatoes with hard brush and emery brush; Uneven and corrugated brush can peel the potatoes completely.

3. Inspecting table

This machine is used to pick out potato eyes and dark parts on potatoes by manually. There will be waste material holes and unpeeled potatoes return system.

4. Water bucket elevator

This machine is used to preclean potato, soften the potato skin, then hoist potatoes into washing and peeling machine.

5. Potato cutter

This machine is used to cut potato into sticks, french fries quality depends on fries length and shape, so cutting machine is very important.

6. Rinsing machine

This machine used to washing potato starch and protect potato from oxidation, keep its original color.

7. Blanching machine

This machine is used to deactivate the activity of the oxidase, take off the starch, separate out the reducing sugar, also after blanching,it will get inner soft taste of french fries.

8. Vibration de-water machine

Used to remove water.Also have many holes at the end of machine to leak out small part and waste part potato.

9. Air-dryer machine:Remove water, drying fries

10. Continuous frying machine:This machine is used to unified fry sticks in short time.

11. Vibrating de-oil machine:This machine is used to de-oil with the vibrating.

12. Cooling line:Use fan to blow off the water on stick surface, then deliver sticks into the freezer.

13. Conveyor :Used between cooling line and quick-freezing machine.

14. Fluidized-type freezer

It is used to quick freezing the french fries in short time, fries center temperature at -18 ºC, Can the maximum keep the original flavor and product quality.

15. Conveyor:Used between quick-freezing machine and packing machine.

16. Automatic weighing and packing machine

It is used to pack the frozen french fries automatically, including bucket Elevator.

| 1:Hoister | 2400x700x1600mm | 10:Air-dryer machine | 6000x1100x1600mm |

| 2:Washing&peeling machine | 3400x900x1500mm | 11:Hoister | 1800x800x1300mm |

| 3:Inspecting table | 4000x800x900mm | 12:Continuous frying line machine | 6000x1200x2400m |

| 4:Potato cutter | 950x800x950mm | 13:Oil filter | 400x400x800mm |

| 5:Water bucket elevator | 2400*800*1500mm | 14:Vibration de-oil | 1800x1000x1200mm |

| 6:Miscellaneous machine | 3000x1000x1300mm | 15:Drying line | 6000x1100x1600mm |

| 7:Rinsing line machine | 4000x1200x1400mm | 16:Hoister | 3000x800x2000mm |

| 8:Blanching line machine | 6000x1200x1400mm | 17:IQF Tunnel Freezer | 8000x3900x2900mm |

| 9:Vibration de-water machine | 1800x1000x1200mm | 18:Automatic weighing and packing machine | 3000x3000x2600mm |

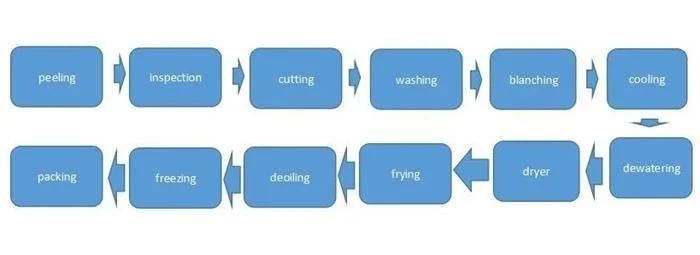

Processing Procedure details

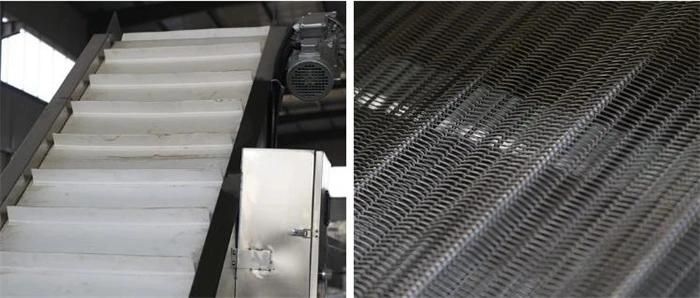

Device Details

Device Details

Company information

Comtact us

Comtact us

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23