Diamond and CBN Grinding Wheels for Iseli Machines Shape 3V1, 6A9

Guangzhou Huiyumei Packing Materials Co., Ltd. / 2022-06-27

- Manufacturing Process:Sintered

- Shape:Cup-Shaped

- Bonding Agent:Resin

- Transport Package:by Box

- Trademark:bondflex

- Origin:Jiangsu China

=== Base Info ===

- Model NO.:type 6

- HS Code:68042210

- Production Capacity:30000 Ton,Year

=== Description ===

Basic Info.

Model NO. type 6 HS Code 68042210 Production Capacity 30000 Ton/YearProduct Description

Our factory is one of leading company in the manufacturing industry of abrasive tools, grinding wheels, cutting, ceramic grinding wheels, synthetic resin bonded grinding wheels, cut-off wheels, diamond and CBN super abrasive tools since 1961Our products including:

Resinoid Diamond & CBN wheels

Vitrified Diamond & CBN wheels

Electroplated Diamond & CBN Tools

Hybrid Diamond & CBN wheels

Diamond & CBN Wheels for Round Tools, drills, end mills and reamers

Diamond & CBN Wheels for grinding tungsten carbide tipped saw blades and one-piece HSS saws

Tool grinding Wheels For surface grinding and tool & cutter grinding

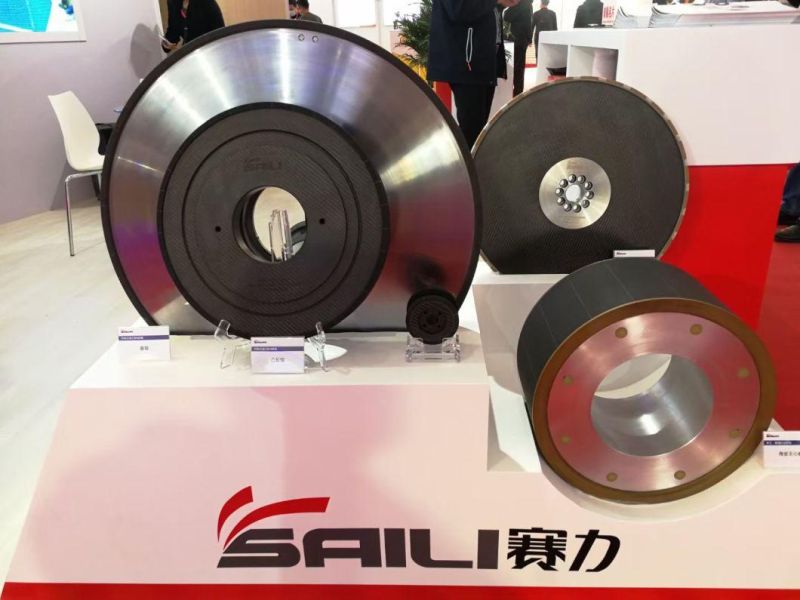

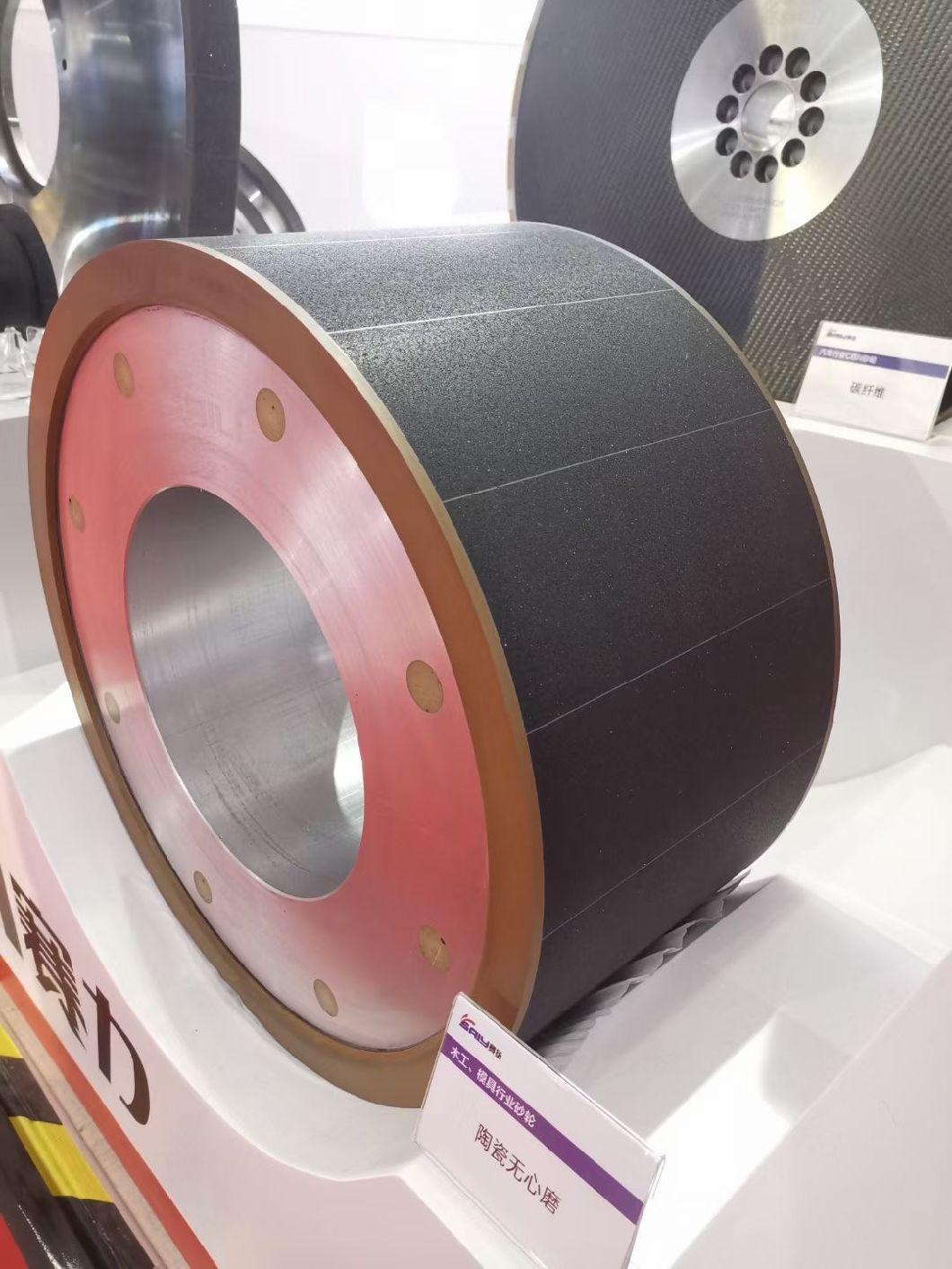

Center less Grinding Wheels

Cylindrical Grinding Wheels

Surface Grinding Wheels

Our factory is one of the leading abrasives manufacturer with ISO9001: 2000 certificate in China. We specialise in the production of high quality diamond & CBN grinding wheel...

Our grinding tools ( diamond & cbn grinding wheel ) for the machining of hard materials comprise the complete range of international used shapes and geometries.

The tools are mainly used in the following bonding systems:

Resin Bond

Uncomplicate grinding operations with good material removal rates are typical for resin bonds. The mechanical and thermal influence on the workpiece is very low. A wide range of special adapted bonds are available

For periphery and top & bottom grinding of indexable inserts, grooving tools and wear parts

For CNC tool grinding of TC drills and cutters

For cutting and OD grinding of TC rods

For flat grinding of wear plates

Sintered Metal Bond

These extremely wear resistant and profile consistent bonds are used for

Profile grinding operations

Crushing (profiling method)

Periphery grinding of indexable inserts (special open bonds)

Grinding of flutes in TC drills and cutters (special bonds in sonor-line)

Grinding of polycrystalline materials like PCD and PCB (CBN) with soft bonds (see below)

Vitrified Bond

The advantage of the vitrified bond is the excellent cutting ability and profile ability combined with good wear and profile resistance. The fine vitrified bonding structure is specially suitable for wheels with micro grit diamond. Vitrified diamond grinding wheels are increasingly used for

Grinding of polycrystalline materials like PCD and PCB (CBN) (see above)

Profile grinding of TC threading plates (including crushing)

OD grinding of paper rolls, shafts and rods

Flat grinding of ceramic components

Electroplated (Galvanic) Bond

Electroplated grinding tools stand out due to extraordinary good cutting ability. Balancing the low life time which is caused by the single diamond layer, the tools can be replated several times. Main applications are:

Grinding of slots in hard materials

Various profile grinding operations

Cutting of ceramic parts (e. G. Catalysts)

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23