Sjsp138/32 Parallel Twin Screw Spc Production Line

Forsun Ultra-hard Material Industry Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

SJSZ 138/32 parallel twin screw extrusion lineNO. Machine Item Qty Unit 2.01 138/32 parallel twin screw extruder 1 Set 2.02 Five-Rollers Calendar 1 Set 2.03 On-line EIR Hardware 1 Unit 2.04 Rollers oil Heating System 1 Unit 2.05 Wind Curtain Machines 6 Set 2.06 Traction Machine 1 Set 2.07 Air cooling cabinet 1 Set 2.10 Stainless steel roller conveyor 1 Unit 2.11 Slabs cutting machine 1 Unit 2.12 Automatic flipping & Stacking System 1 Unit 2.13 Automatic transposition stacking pallet 1 Unit 2.14 1350mm extrusion T-die 1 Pc

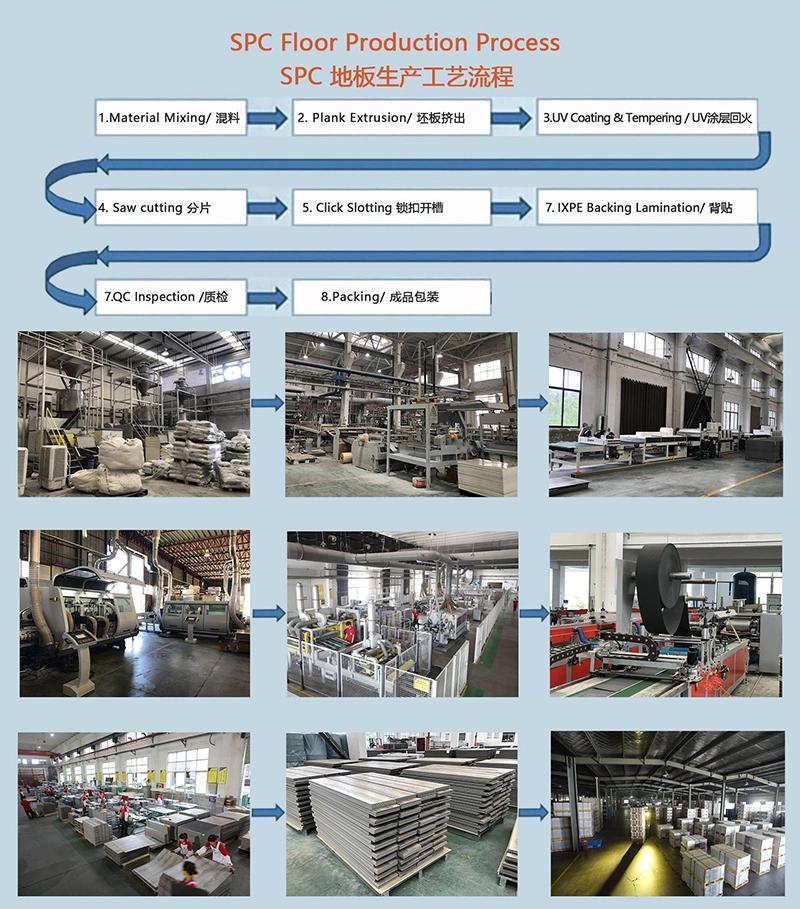

III.Production Flow

Material mixing → Extruder → Calender→ Cut-to-length →Stacking →UV coating →Saw cutting →

Slick slotting →Backing limitation →QC inspection → Packing

IV. Main Processing Steps

1. Material Mixing→ screw conveyor from 8m3 Silo (~5 Tons) → Feeding recipe material into the hopper loader → Extruder → Material Plasticizing → Extrusion through T-die → Five Roller Calender

2. Plank extruded from T-die→ Five Roller Calender →Thickness calibration on 1# & 2 # rollers → Wearing film & decorative film laminating on 3 # roller → Temperature reduction on 4# silicon roller → On-line embossing (EIR) on 5# roller → Edges trimming

3. Plate conveying from 5 roller calender→ Edges Trimming → Roller Cooling Bracket →Air Cooling Cabinet → Traction Machine→ Cut-to-length machine →Automatic Flipping & Stacking Machine

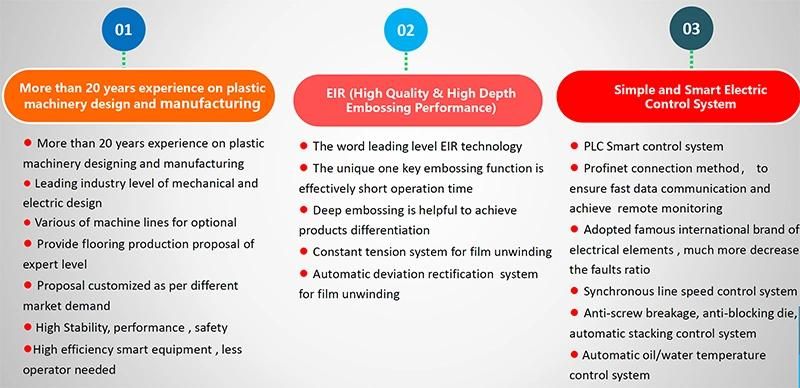

V. Advantages of BOYU WPC Production Machine Line

VI.Services

VII. Project Case

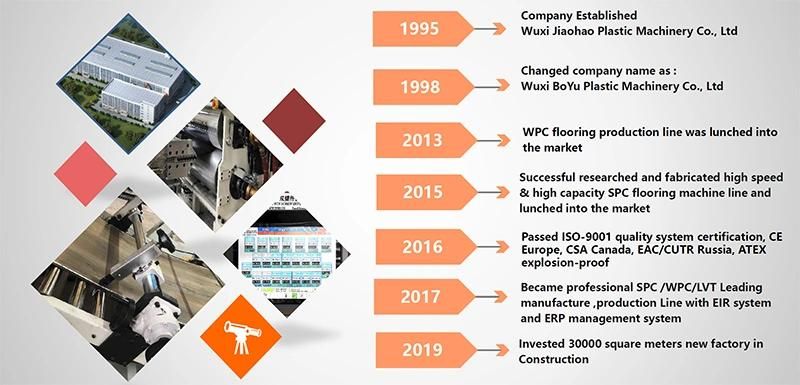

VII. Boyu Company Profile

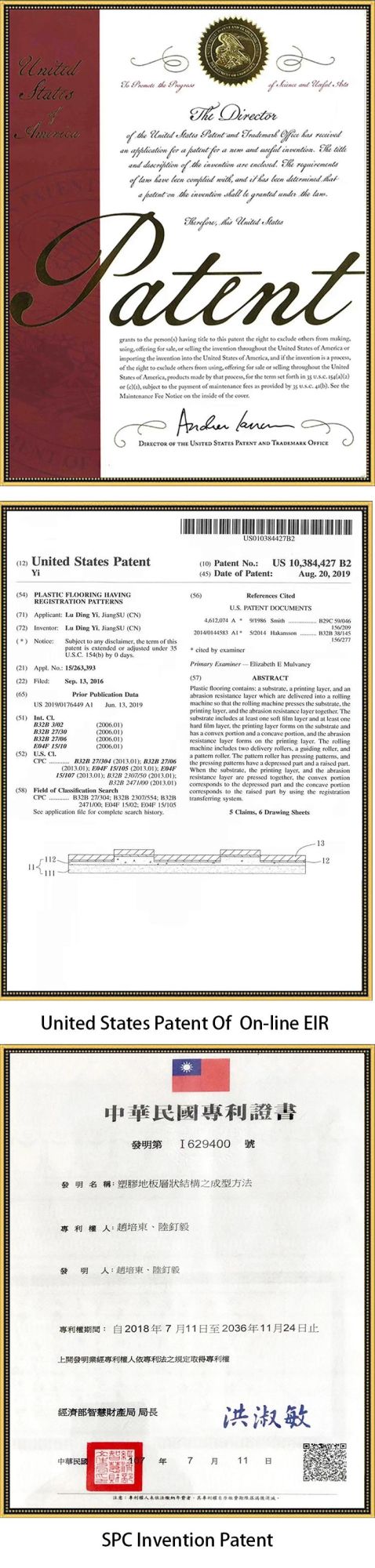

VIII. Patents Certificates

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23