Plastic Pet Bottle Washing Machine/Pet Bottle Washing Line

Taizhou Shangzheng Hydraulic Tools Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. BDX Application Plastic Pet Bottle Recycling Machine Material Stainless Steel 304 Final Pet Flake Water Content Less Than 3% Final Product Clean Flakes Main Motor Siemens PLC Siemens Contactor Schneider Delivery Date 45days Payment Type T/T or L/C Transport Package Wood Case or Plastic Film Specification CE and ISO SGS Trademark Sevenstars Origin Zhangjiagang HS Code 8477201000 Production Capacity 300-3000kg/HrProduct Description

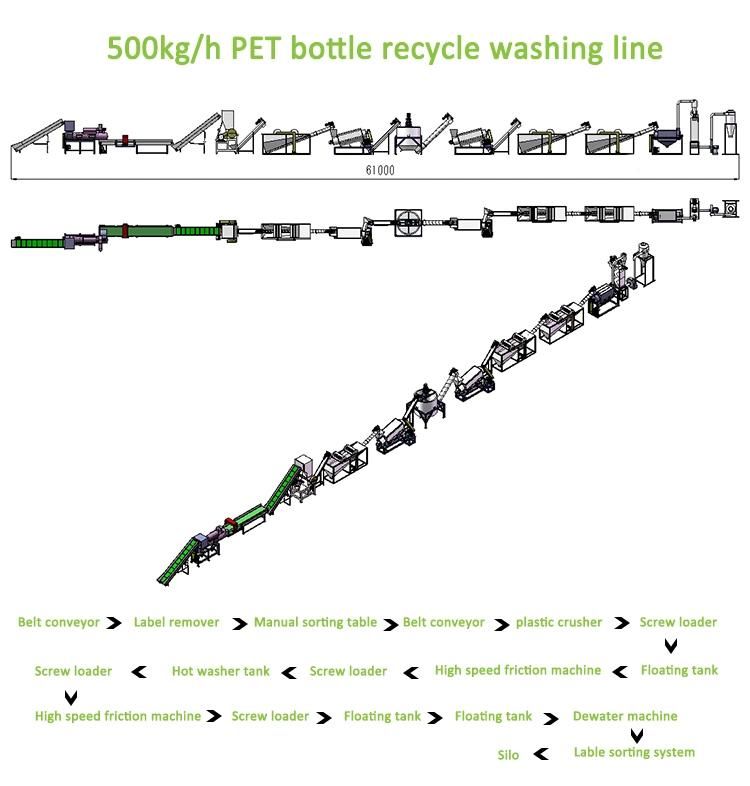

Plastic PET bottle washing machine / PET bottle recycling machine / plastic bottle washing line / PET bottle flake washing line

Product Description

The whole production line is researched,design and manufactured for pet bottles,barrels etc.

1. researched,designed and manufactured by our company, integration of European technology

2. high efficiency

3. working stable

4. large capacity etc.

5. Final product of good quality, low humidity content(less than 2%) and less impurities(less than 400PPM).

6. SUS-304,more than 3mm thickness,ensures whole production equipment long service life time.

Applications:

1. This washing,recycling line is mainly used for dealing with waste hdpe bottles/barrels,

PP barrels, PET bottles/Lumps etc.

2. Realizing one production line can process different material.

The whole production line is surely of standard and high quality with CE certification and ISO9001:2000.

Specifications :

No. | Equipment Name | Quantity | Comments |

1 | Belt conveyor | 1 set | |

2 | Bag opener | 1 set | Optional |

3 | Belt conveyor | 1 set | |

4 | Trommel | 1 set | Optional |

5 | Belt conveyor | 1 set | |

6 | Manual sorting conveyor | 1 set | Optional |

7 | Belt conveyor | 1 set | |

8 | Crusher | 1-2 sets | |

9 | Screw conveyor | 1 set | |

10 | Washing tank | 1 set | |

11 | Screw conveyor | 1 set | |

12 | Cooking boiler or Horizontal Hot washer | 1-2 sets | |

13 | Screw conveyor | 1 set | |

14 | High-speed washer | 1 set | |

15 | Washing tank | 1 set | |

16 | Screw conveyor | 1 set | |

17 | Horizontal Dewatering Machine | 1 set | |

18 | Cyclone separator | 1 set | |

19 | Drying system | 1 set | |

20 | Label separator | 1-2 sets | We can equipped with two label separators in the whole line, one at the beginning, another at the end |

21 | Final product silo | 1 set | |

22 | Control System | 1 set |

Our Service :

1. Purchase Service

We have a specialized and efficiency working team. If you are new on the Plastic Machinery area, Some samples of your products could be show to us will be appreciated ,we will give you specialized suggestion of whole work .

2. Shipping Service

We have a specialized and independent department which just for shipping the buyer's goods .The workers are knowing T/T, L/C Items very well. All Exported documents could be made perfectly.

We cooperated with the most famous shipping company in China also. They could provide the best and economic shipping ways to the buyer's port.

3.Installation and Training Services

Installation Services are available with all machines. We will dispatch technician to The Buyer's factory to installation and preoperation of machines .But the buyer need to supply the round trip tickets ,food ,hotel and other cost.

Training on our factory also be welcome.

4.After Sales Service

Our machines guarantee time is one year.

Many easy broken spare parts will be prepared in the tool box together with machines.

Any parts broken, Just a pictures or a videos.Then new free parts will reach within 3-7 Express working days .

If need know more about our machines/price/service:

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23