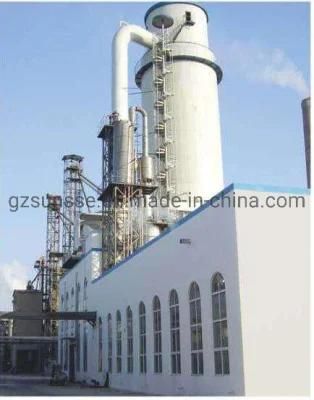

Automatic Control Corn/Maize Starch Plant Machine

Jiangsu Zhengheng Light Industrial Machinery Co., Ltd. / 2022-07-04

- Certification:CE, ISO9001

- Customized:Customized

- Application:Corn,Corn Starch,Rice Starch

- Processing Material:Agronomic Products

- Power Source:Electric

- Automatic Grade:Automatic

=== Base Info ===

- Transport Package:Customized

- Installation Time:2-6 Months

- Process:Corn Wet Mill

- Capacity:1000 Tons -3000 Tons Per Year

- Final Product:Corn Starch, Germ, Fiber, Gluten

- Product Name:Corn Starch Plant Equipment

- Model NO.:SUNSSE

- Specification:Design as Required

- Trademark:SUNSSE

- Origin:China Guangzhou

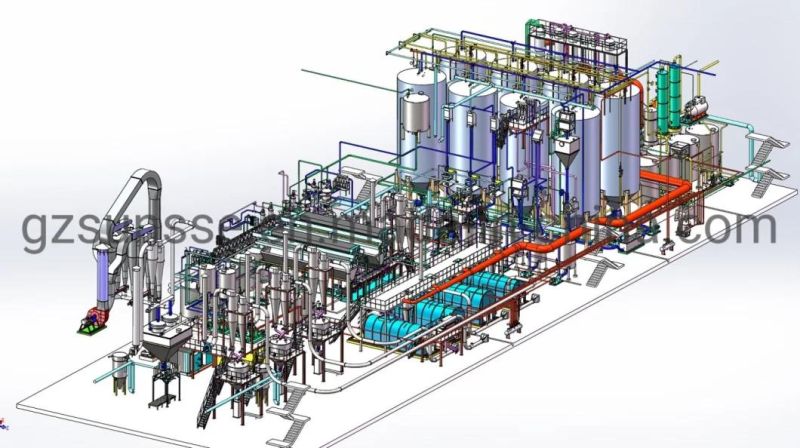

=== Description === Degerming Mill is mainly used to grind corn after steeping and working together with germ cyclone to separate corn germ from germ milk. In order to increase recovery rate of corn germ, two-stage crumbling process is recommenced. SUNSSE Centrifugal Separator is used in starch processing for starch milk pre-concentration, starch milk washing and concentration and, protein dewatering and concentration.

Degerming Mill is mainly used to grind corn after steeping and working together with germ cyclone to separate corn germ from germ milk. In order to increase recovery rate of corn germ, two-stage crumbling process is recommenced. SUNSSE Centrifugal Separator is used in starch processing for starch milk pre-concentration, starch milk washing and concentration and, protein dewatering and concentration.

1. Unique hanging-type driving mechanism eliminating axle load on the shaft and bearings and thus effectively increasing working life.

3. Large-size nozzles complete with cam-lock device minimizing blockage possibilities and enabling long-time continuous separation.

4. High precision dynamic balancing process adopted in rotor fabrication process ensuring smooth rotation and running.

5. Temperature sensors on each bearing providing real-time monitoring of the bearing condition.

6. Vibration sensor on the main shaft assembly providing real-time monitoring of operational parameters.

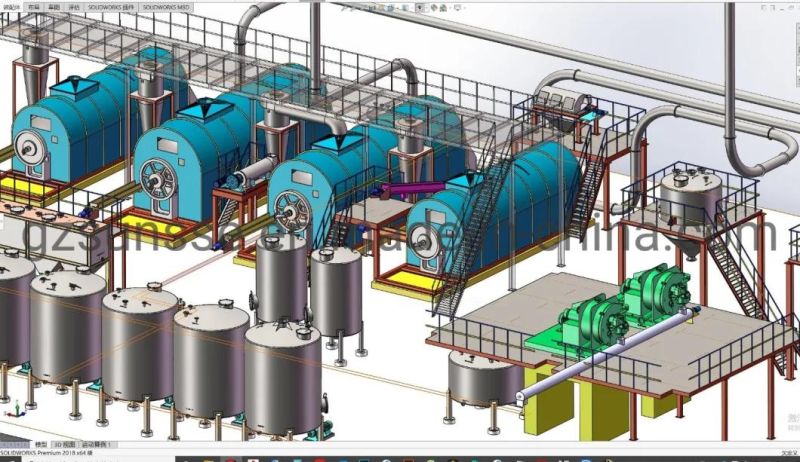

SUNSSE Dwatering Screw Presses is suitable for the dewatering of fibers in corn starch production, and also for the dewatering of similar coarse fiber materials in other industries.

SUNSSE Dwatering Screw Presses is suitable for the dewatering of fibers in corn starch production, and also for the dewatering of similar coarse fiber materials in other industries.

1. This machine can be produced continuously with high dewatering efficiency.

2. Simple structure, easy to use and repair.

3. The whole machine has compact structure, small floor space and convenient transportation.

4. The starch-containing residue can be recycled, which can not only reduce the cost and improve the economic efficiency, but also improve the production operation environment.

The tube bundle dryer is mainly used to dry corn germ, gluten, and fiber.1. Low heat consumption.

2. Large capacity and high moisture evaporation capabilities making it suitable to process high moisture content materials.

3. High adaptability (capable of adjusting drying time based on material properties and processed material moisture requirement).

4. High degree of automation making it suitable for both continuous processing and batch operation as may be required by special applications.

5. Effectively insulated chamber in which drying takes place in negative pressure condition-resulting in the clean work area and minimized noise.

6. Compact design with minimum auxiliary equipment and reduced consumable parts, easy installation and low maintenance cost.

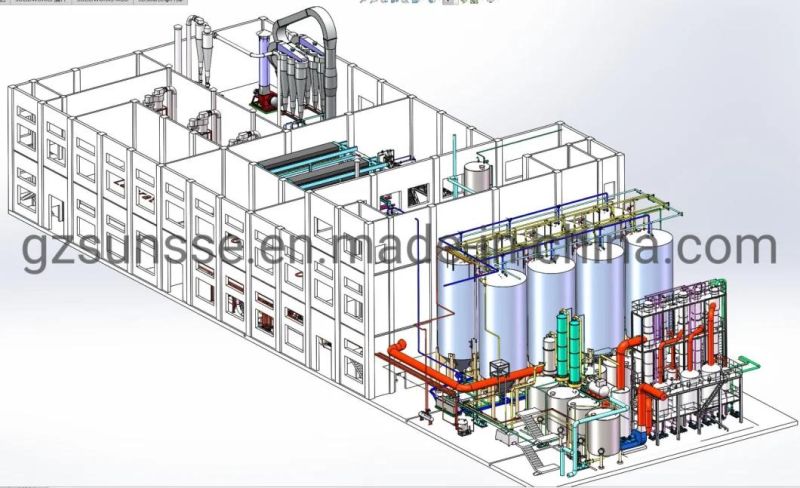

SUNSSE rotary drum vacuum filters have a filtration area of up to 200 m2 and the drum speed can be adjusted to the thickness of the filter sludge. The drum speed is mostly from 0.1 to 10 minutes per revolution. The absolute pressure of the operating vacuum is (0.25 to 0.8) x 10 Pa. The temperature of the filtered suspension should be lower than the vaporization temperature of the filtrate under the operating vacuum. This filter has a large capacity, is easy to operate, and the filter residue can be washed.

SUNSSE rotary drum vacuum filters have a filtration area of up to 200 m2 and the drum speed can be adjusted to the thickness of the filter sludge. The drum speed is mostly from 0.1 to 10 minutes per revolution. The absolute pressure of the operating vacuum is (0.25 to 0.8) x 10 Pa. The temperature of the filtered suspension should be lower than the vaporization temperature of the filtrate under the operating vacuum. This filter has a large capacity, is easy to operate, and the filter residue can be washed.

The starch washing system is mainly used to extract refined starch and remove soluble and insoluble proteins and micro fibers contained in the starch milk.

State-of-the-Art mechanical design

1. No internal leakage: optimal sealing

2. Pumps: single mechanical seal with internal flush

3. High wear resistant cyclonettes

4. Compact Design: serial and stacked

5. Easy operation, service & maintenance

6. Full capacity flexibility

7. Excellent performance

8. High outlet concentration (> 22Be)

9. Excellent starch yield

10. Low energy consumption

11. Minimum down time

12. Cleaning-In-Place (CIP)

13. Full stainless steel

14. Sustainability and long lifetime

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23