Cooking Oil Negative Pressure Solvent Extraction Desolventizing and Condensation Equipment

Shenzhen Xiangfeizhu Technology Co., Ltd. / 2022-07-05

- Type:Pressing Machines

- Application:Oil Seeds

- Voltage:220V

- Appearance:Vertical

- Press Materials:Soybean

- Press Series:Second

=== Base Info ===

- Model NO.:Huatai-Sesame

- Condition:New

- Customized:Customized

- Capacity:20tpd-3000tpd

- Extractor Type:Rotary, Chain, Loop

- Desolventizer:Dt, Dtc, Dtdc

- Transport Package:Bulk

- Specification:Customized

- Trademark:Huatai

- Origin:China

- HS Code:84792000

- Production Capacity:10sets,Year

=== Description ===

Basic Info.

Model NO. Huatai-Sesame Condition New Customized Customized Capacity 20tpd-3000tpd Extractor Type Rotary, Chain, Loop Desolventizer Dt, Dtc, Dtdc Transport Package Bulk Specification Customized Trademark Huatai Origin China HS Code 84792000 Production Capacity 10sets/YearProduct Description

Solvent extraction

The processing of vegetable oil in commercial applications is commonly done by chemical extraction, using solvent extracts, which produces higher yields and is quicker and less expensive. The most common solvent is petroleum-derived hexane. This technique is used for most of the "newer" industrial oils such as soybean and corn oils

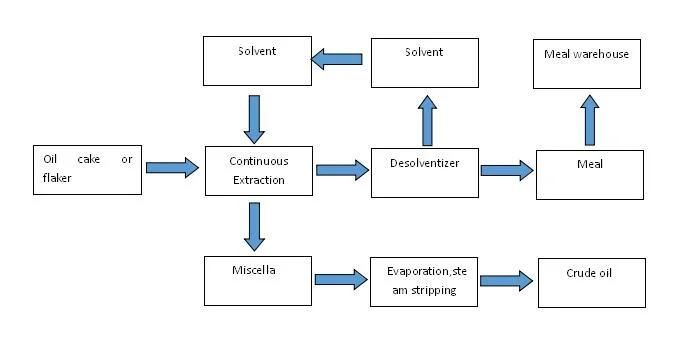

Solvent Extraction Flow Chart

A Continuous extraction

Material enters the buffer bin on the extractor firstly,the buffer bin is equipped with automatic material level control system, use variable frequency feeding screw conveyor to feed materials into extractor quantitatively .The materials run a circle from feed inlet to outlet in extractor, and spray with miscella with descending concentration between inlet and outlet, before entering drain section, spray with fresh solvent again, at last the wet meal discharges from the bottom of extractor, enters wet meal scraper. Concentrated miscella is pumped to cyclone hydraulic separator by pump to remove meal powder, then enter the miscella tank to further remove the impurities.

B .DTC desolventizing DTC

The wet meal discharged from the bottom of extractor is conveyed into upper part of the pre-desolventizing layer of DTC with scraper, heating with indirect steam, make part of solvent evaporate, meal temperature rises; pre-desolventized meal falls into desolventizing layer, utilize secondary steam from desolventizing layer to remove the solvent from the meal, later meal falls into desolventizing layer, feed direct steam, the steam is injected into meal from small holes at the bottom for steam distillation of solvent in meal,to remove the solvent,part of steam condenses in the meal, play a role in destroying active enzyme in the meal;the desolventized meal falls to the bottom of drying layer by discharge valve for drying,the dried meal is cooled in the cold air layer and then discharged by scraper and sent to the meal warehouse by the horizontal scraper.,

C.Evaporation, steam stripping

The miscella through the cyclone hydraulic separator go into the No. 1 evaporator, the DT vent can be used as the heating source of the NO. 1 evaporator. The evaporated solvent discharge into the evaporator condenser through the top of No. 1 evaporator separator, the vacuum of evaporator condenserkeep by the steam ejector. The concentrated miscella discharge from the No. 1 evaporator separator at the bottom, heated by the miscella heat exchanger and entered into the No. 2 evaporator. The No.2 evaporator use the indirect steam heating. The evaporated solvent gas go into the evaporation condenser with the solvent gas evaporated by the No.1 evaporator. The No.1 and No.2 evaporator are in the same vacuum. The second concentrated miscella flow out from the No.2 evaporator separator, pumped into the upper of oil stripper. The steam go into the oil stripper from bottom, remove the residue solvent in the miscella. The vents go into the stripper condenser,the vacuum in the oil stripping condenser maintained by high vacuum jet pump. At the bottom of the steam stripping tower, there is alevel control apparatus, which can guarantee the steady flow of the liquid seal and finished oil. The crude oil draw out by the stripper pump,after cooling, the crude oil pump into the oil storage tank.

,

.D.Solvent cooling and water separation section

Uncondensed vapor of the stripping condenser is pumped into the shell pass of No.1

evaporator by vacuum jet pump, uncondensed vapor of the evaporation condenser is pumped

into the shell pass of No.1 evaporator by vacuum jet pump, uncondensed vapor of shell pass

of No.1 evaporator enters the bottom of energy saver, heat exchange with fresh solvent, the vapor that has not been condensed enters the atmospheric condenser for further condensate. Condensate of evaporation condenser and steam-stripping condenser is pumped to water separation tank.The condensate of the first evaporator, the economizer shell condensate and other condensers flows into the water separator, and after the water is separated, the solvent enters the solvent turnover library.The fresh solvent pumped to the economizer to heat exchange and enter the extractor for recycling. The wastewater separated by the water separator enters the steaming water tank,after evaporated the residual solvent and discharged into the water sealing tank.

2.2.5 Tail gas absorption

Uncondensed vapor out from vent condenser enters from the bottom of absorber, lean

oil sprays down from the upside of the absorber, counter currently contact vent through packing

layer to absorb solvent, absorbed vent discharges into atmosphere by vent fan through flame

arrester from the top of absorber .

Rich oil which absorbs solvent is pumped into the heat exchanger between lean oil and rich oil, then heated by rich oil heater, and enters tower from the upside of desorber, inject direct steam from the bottom of oil stripper to desorber, desorpted gas enters evaporator condenser, lean oil enters absorber to recycle after heat exchanging and cooling.

.

2.3 Process features

1.Adopt loop extractor and big capacity recycle pump, with advantages of good permeation effect and lower solvent rate in the meal, make sure the residual oil in meal not more than

1.0% under the circumstance of smaller material-solvent ratio. It can improve theconcentration

of the miscella, reduce the solvent in the meal,and reduced solvent evaporation greatly.

2.Adopt negative pressure evaporation, reduce evaporation temperature, use DT vent from DTDC and the steam from steam-jet pump to heat No. 1 evaporator,saved heating

steam of No. 1 evaporator.

3.Use heat exchanger in paraffin recovery process, exchange heat between high temperature paraffin lean oil and low temperature paraffin rich oil, which saves part of heating.

4.Adopt superior steam trap to reduce steam consumption in workshop, at the same time, collect all the steam condensate and pump into it to the boiler room for recycling, economize soft water and thermal energy.

Crude extraction oil Quality:

| Item | Quality index |

| Moisture and volatile matter ≤ | ≤0.2% |

| Insoluble impurities≤ | ≤0.2% |

| Residue solvent in crude oil ≤ | ≤100ppm |

| Item | Consumption index |

| Electricity consumption ≤ | ≤17.5kwh/t (including forbidden area facility) |

| Steam consumption ≤ | ≤250kg/t |

| Solvent consumption≤ | ≤1.6kg/t |

| Cooling water consumption | The 1%-3% of circulating water quantity |

- Electric consumption , not include the outside equipment of extraction plant (such as the

- steam consumption is based on steam gauge pressure 8-10bar(G), and environment

- Solvent consumption is based on commercial n-hexane, and boiling point range 66-69ºC

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23