PVC WPC Window and Door Profile Panel Ceiling Decking Production Extruder Extrusion Line ...

Ningbo Conwhole Hardware Co., Ltd. / 2022-07-04

=== Base Info ===

=== Description ===

Basic Info.

Model NO. SJSZ65/132 Customized Customized Contacctor Siemens Converter Delta Cooling Method Air Blowing Inverter Teco Products Breaker Siemens Buttons France Te Temperature-Controller Omron Transport Package Wooden Packing Specification Customized Trademark Trusty Origin Qingdao HS Code 84772090 Production Capacity 30 Sets/MonthProduct Description

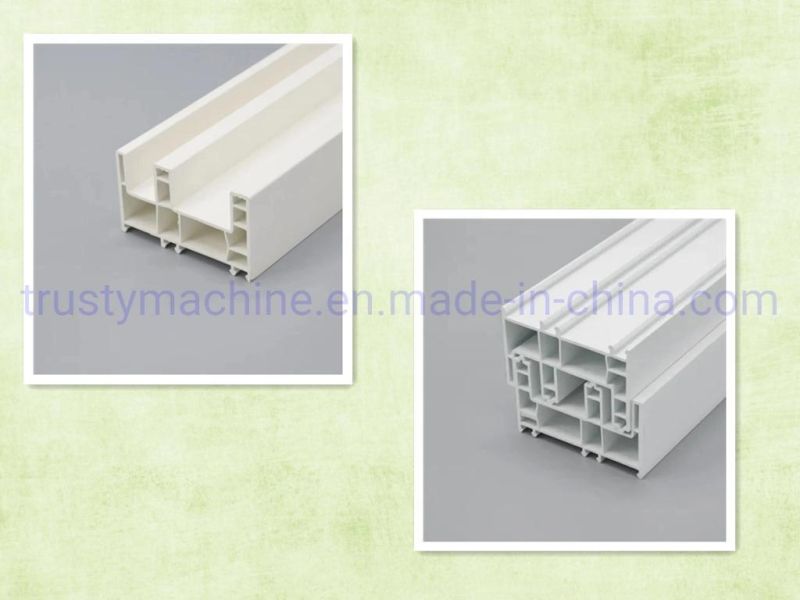

PVC WPC window door profile panel ceiling decking fencing make making extruder machine linePVC window and door profile Extrusion Line

Raw materail: PVC+Other chemical

Product Introduction:

The PVC door and window profile production line can choose different specifications of conical twin-screw extruders according to different profile sections and molds, and configure the corresponding vacuum calibration table, tractor, cutting machine, stacker and other auxiliary equipment.

Technical Parameter:

| Model | TPM-180 | TPM-300 | TPM-600 |

| Max.width of product(mm) | 180 | 300 | 600 |

| Extruder model | SJSZ-51/105 | SJSZ-65/132 | SJSZ-80/156 |

| Extrusion capacity(kg/h) | 180 | 250 | 350 |

| Motor power(kw) | 22 | 37 | 55 |

| Total length(m) | 18 | 22 | 26 |

PVC/WPC Ceiling/Wall Panel Extrusion Line

Product Introduction

PVC profile production line is composed of cone twin screw extruder, vacuum calibration tank, haul-off, cutter, stacker, and also coordinated with different profile break-section and mould to produce PVC door&window profile,indoor floor, decoration plate material, profile and multi-hole wire plastic products etc.

This extrusion line also can be used to produce wpc profile extrusion line WPC Machine can be used after recycling, and has been widely used in fields of floor, guard bar, tray, packing cases, partition board, window and door sheath, skirting line, etc. Advantage of PVC/WPC wall panel1.Easy installation,it can be installed directly onto concrete wall

2.No glue, the PVC/WPC wall panel are extruded directly, no glue used. Good for environment.

3.Multiple color choice. The PVC / WPC wall panel apply film lamination, so you can choose design and color which you like.

4.Easy to change. After use several years, if you want to redecorate the house, it is easy to take off from the wall and change to another design.

PVC/WPC Door Panel Extrusion Line

Product Introduction

The PVC WPC door panel extrusion line is suitable for producing the preparatory PVC WPC door panel.

We can provide the turnkey project for integrated door and door frame.

The whole production line includes the PVC WPC door frame extrusion line, WPC door panel extrutsion line and subsequent processing equipments.

The PVC WPC door has the advantages of fireproof, waterproof, anticaustic, moistureproof, mothproof, mildewproof and environmentally friendly.

The PVC WPC doors can be widely used in interior doors, hospitel ward doors, school classroom door, various styles can be customized.

Technical Parameter

| TPM-800 | TPM-1000 | TPM-1200 | |

| Extruder Model | 80/156 | 92/188 | 92/188 |

| Max.Width | 800mm | 1000mm | 1200mm |

| Max.Extruder Capacity | 350kg/h-380kg/h | 450kg/h-500kg/h | 500kg/h-550kg/h |

| Main Motor Power | 90KW | 110KW | 110KW |

| Door Thickness | 20-50mm | 20-50mm | 20-50mm |

PE WPC Profile Extrusion Line

Used for:

PE WPC DECKING,FENCING,WALL CLADDING,BENCHES,PERGOLA,BEAM

Raw material:

100%Recycled PE granules(30%)+Wood Powder(65%)+chemical(5%)

Technical Parameter

1)For Pelletizing Production Line

| Model | L/D ratio | Max.capacity | Motor power | Suitable material | Max.rotating speed | Wood powder percentage |

| SHJ-65 | 40:1 | 200-220kg/h | 75kw | Pe+wood powder | 500r/min | ≤75% |

| SHJ-75 | 40:1 | 300-350kg/h | 90kw | Pe+wood powder | 500r/min | ≤75% |

| Model | TPM-65 | TPM-80 |

| Extruder model | SJSZ-65/132 | SJSZ- 80/156 |

| Motor power | 37kw | 75kw |

| Mac.Extrusion capacity | 140-160kg/h | 220-250kg/h |

| Co-extruder(Optional) | SJ35/28 | SJ45/28 |

Main Production Line

1.SRL 500 Mixer

2.PE-WPC Pelletizing Production line

1)SHJ65/40 Parallel Twin Screw Extruder

2)SWP-380 Crusher

3)Three Stages Wind Cooling&Conveying System

3.PE-WPC Profile Production LIne

1)SJSZ65/132 Conical Twin Screw Extruder

2)Mould

3)Calibration Table

4)Cutting Machine

5)Stacker

4.Sanding Machine

5.Embossing Machine

6.Brushing Machine

About us

About usQingdao Trusty Plastic Machinery Co., Ltd. is a professional plastic extrusion equipment

manufacturer integrating design, research and development, production and sales.

The company's main products are rich, the production technology is mature, and the after-sales service is guaranteed. Products are sold at home and abroad, such as: Brazil, Chile, Mexico, the Philippines, Italy, Russia, Pakistan, Vietnam, India, Algeria, Egypt and other countries.

Our company is located in Qingdao, one of the plastic machinery bases in China, where the railway, sea transportation, aviation and other transportation systems are very complete. And it is one of the regions with rapid economic development in the coastal cities.The advantaged geographical conditions have provided great convenience for the development of the company's trade.

Our company's main products are:

PVC door and window profile production line

WPC wood-plastic profile production line

PVC wall panel production line

PVC/PE/PPR/PP pipe production line

PP/PE/ABS board/sheet production line

PVC/WPC crust foam board production line

PE/PP/PC hollow sheet production line

PVC roof tile production line

PP/PET packing belt production line

According to customers' needs, to achieve diversified processing customization.

Over the years, the company has always adhered to the tenet of "honesty for basis, quality for living, innovation as the theme, and development as the focus", abide by the quality commitment to users, and won the trust of customers.

AFTER SALES SERVICES

| Technical documentation |

| All symbols on the equipment will be in English. We will be responsible for providing the Buyer with a general layout plan, electrical plan, installation orientation and manuals, in English. |

| Arrangements for inspection, installation and testing of the equipment |

| a. After all of the equipment is delivered to the customer's factory, the Buyer shall be responsible for all preparation work, e.g. electricity supply, water supply, cranes and labor, etc. b. We will prepare visa applications for their engineers, who will assist in the equipment installation and testing at the Buyer's factory. c. The Buyer will buy a round-trip air ticket for the engineer(s) after the visa application is approved. The Buyer is responsible for all expenses generated, e.g. visa application fees, meals, accommodation and an allowance of $80.00 per day for each engineer. d. The engineer(s) will provide free training for the operators and maintenance people, in Buyer's factory. e. If the Buyer does not request commissioning by our engineer(s) within four months from the date of the bill of lading, it will be accepted that all the equipment has been successfully tested and approved by the Buyer. |

| Quantity and quality guarantee |

| a. In cases of quantity discrepancies or equipment damage, at the destination, the Buyer will file a claim within 30 days after the arrival of the goods at its destination. The insurance company and the shipping company will be responsible for all discrepancies and damage caused by the shipping company or other transportation companies. b. Guarantee period and after-sales services: 13 months from the date of the bill of lading. During this guarantee period, if there is a quality issue, we will provide spare parts without charge. If malfunctions are caused by the Buyer's improper operation of equipment, we will provide the Buyer with spare parts at cost prices. c. Long-term service: Beyond one year, we will provide the Buyer with spare parts at reasonable prices and provide long-term technical guidance. |

New product

Hot product

- Gm Candi Interface

2022-06-23

- Scan Dash V2.0 for BMW

2022-06-23

- K+Can Commander 2.0

2022-06-23

- Mut-3 Professional Diagnostic Tool Mut3

2022-06-23

- CKM-100 Key Programmer for Benz/BMW

2022-06-23

- Fuel Injector Tester & Cleaner (MST-N6A)

2022-06-23

- Mst 9000+ Plus ECU Simulator

2022-06-23

- OBD Ii Code Reader Mst-300, OBD2 Code Scanner

2022-06-23

- Digital Battery Analyzer (SC-100)

2022-06-23

- VAS5052A PC VERSION with VAS5054A Wireless Bluetooth Communicate

2022-06-23